Automatic control method for solution stirring

A solution and stirring container technology, applied in the direction of electric controllers, mixer accessories, chemical instruments and methods, etc., can solve the problems of inability to judge raw materials and waste processing time, so as to improve intelligence and automation, improve efficiency and effect, and simplify The effect of the action steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

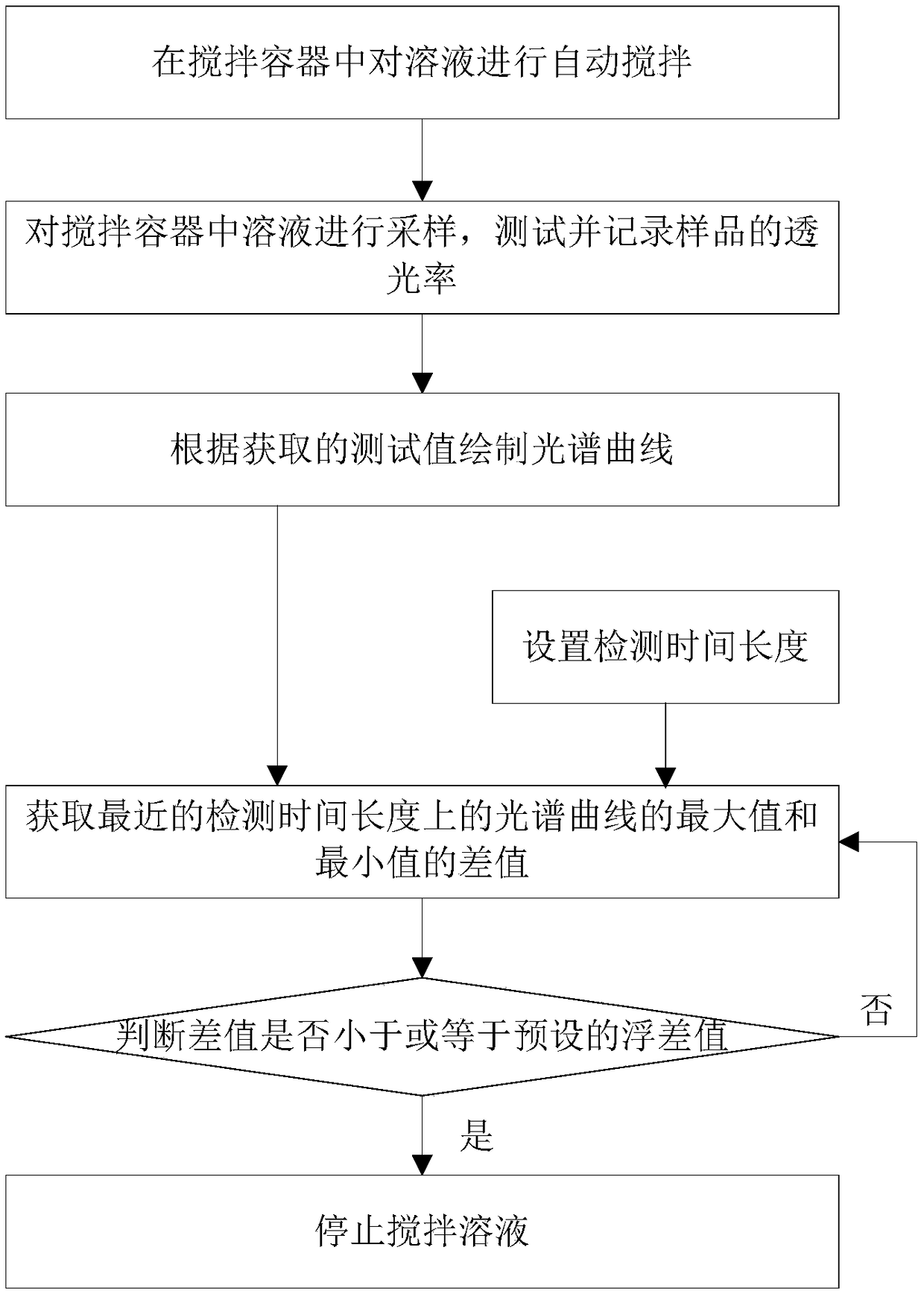

[0028] refer to figure 1 , a kind of solution stirring automatic control method that the present embodiment proposes, comprises the following steps:

[0029] S1. The solution is automatically stirred in the stirring container.

[0030] S2. Sampling the solution in the stirring container, testing and recording the light transmittance of the sample. The transmittance of the solution is determined by its concentration. In this step, the transmittance of the test sample is equal to the concentration of the test sample.

[0031] In this step, the light transmittance of the sample in the sample chamber is tested in real time by the spectrometer 3 . In this step, by converting the concentration detection of the solution into the light transmittance detection, the operation steps are simplified and the operation difficulty is reduced.

[0032] S3. Draw a spectrum curve according to the acquired test value. In this way, through the spectral curve, the change trend of the light tran...

Embodiment 2

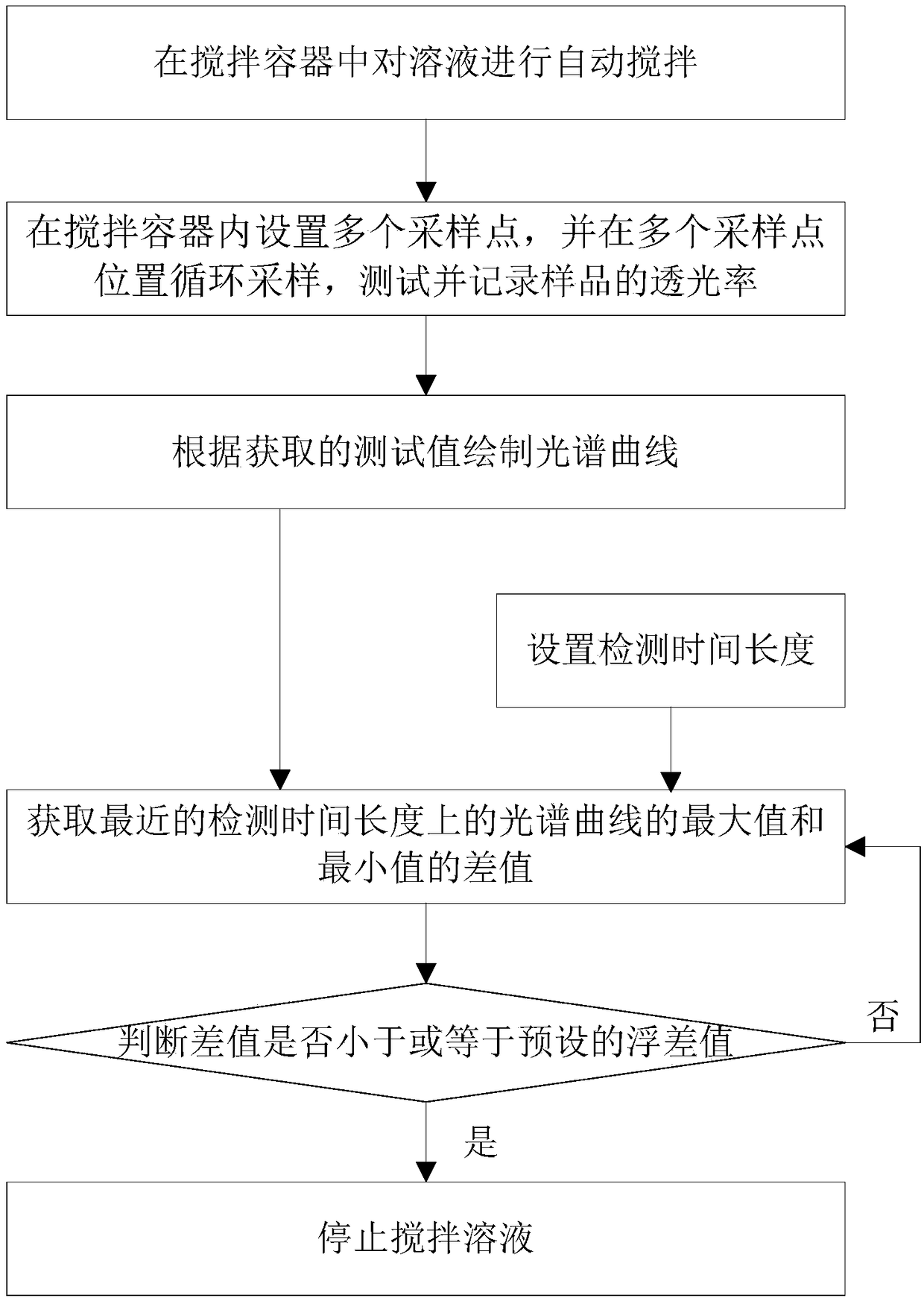

[0039] Compared with Example 1, in step S2 of this example, a plurality of sampling points are set in the stirred vessel, and sampling is carried out in cycles at the positions of the plurality of sampling points. The setting of multiple sampling point positions is conducive to further improving the representativeness of sample collection, realizing the comprehensiveness of the detection of the solution in the stirring container, thereby further improving the accuracy of judging the uniformity of the solution.

[0040] Specifically, in step S2 of this embodiment, a preset sampling time value is set between any two adjacent samplings. Thereby, periodic sampling is realized, and the orderliness of solution detection is improved.

[0041] Specifically, in this embodiment, the detection time length is greater than or equal to the product of the sampling time value and the sampling point, so as to ensure that at least one round of detection of the solution at each sampling point is...

Embodiment 3

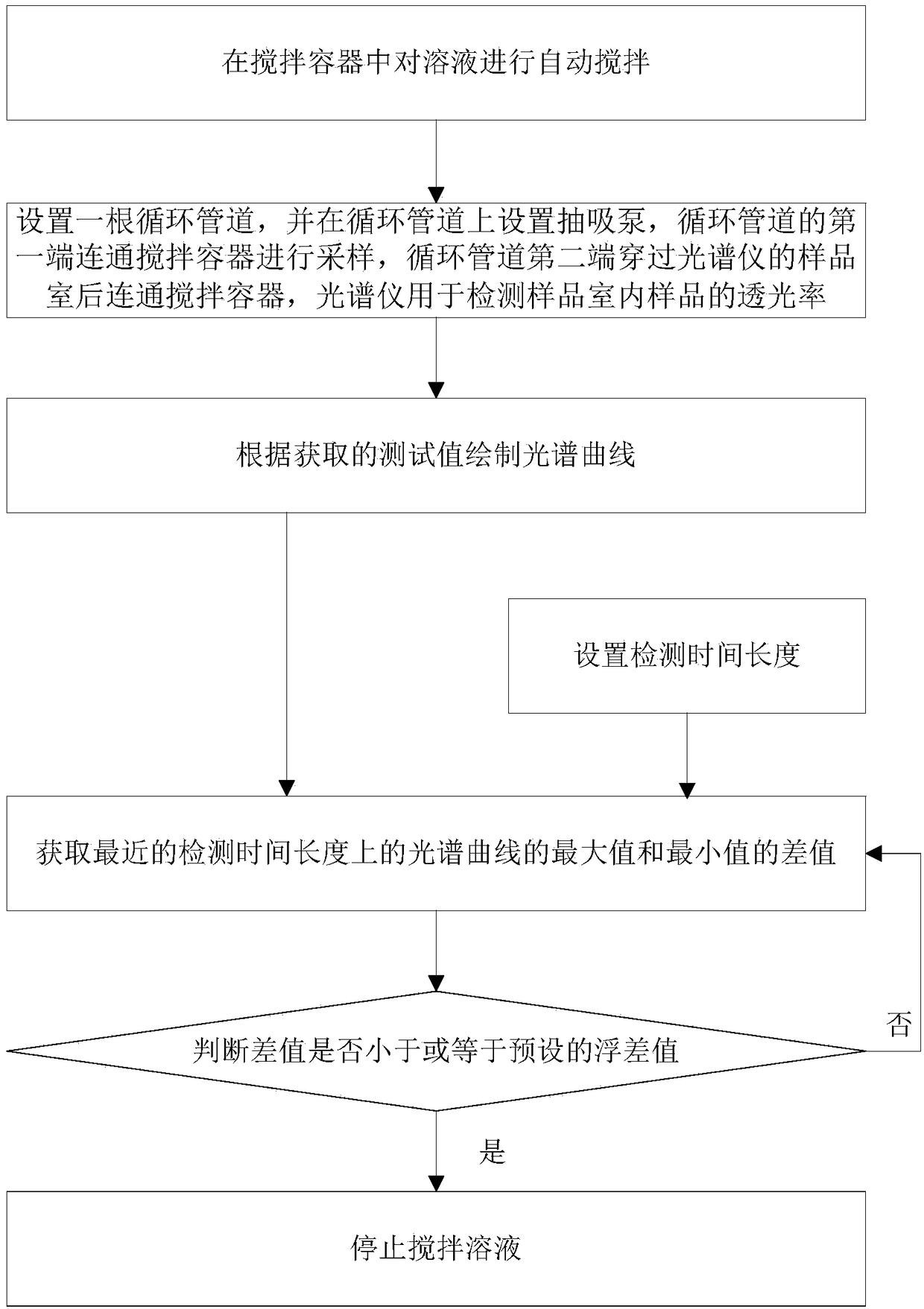

[0043] With respect to embodiment 1, the step S2 of this embodiment is specifically: a circulation pipeline is set, and a suction pump is arranged on the circulation pipeline, the first end of the circulation pipeline 2 is connected to the stirring container for sampling, and the second end of the circulation pipeline 2 After passing through the sample chamber of the spectrometer 3, it is connected to the stirring container, and the spectrometer 3 is used to detect the light transmittance of the sample in the sample chamber.

[0044] In this way, through the spectrometer 3, the solution concentration test is converted into the solution light transmittance test, and the continuous sampling of the solution through the flow channel is realized through the circulation pipeline 2, and the step of extracting the solution from the stirring container is also avoided. The operation difficulty is reduced, the test efficiency is improved, and it is beneficial to ensure the environmental s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com