Metal shell watertight connector

A technology of watertight connectors and metal shells, which is applied in the direction of connection, base/shell, and two-part connection devices, etc. It can solve problems such as plug drop-off, poor reliability, and economic loss, and achieve the goal of ensuring sealing and waterproofing, avoiding wear and tear, and ensuring life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

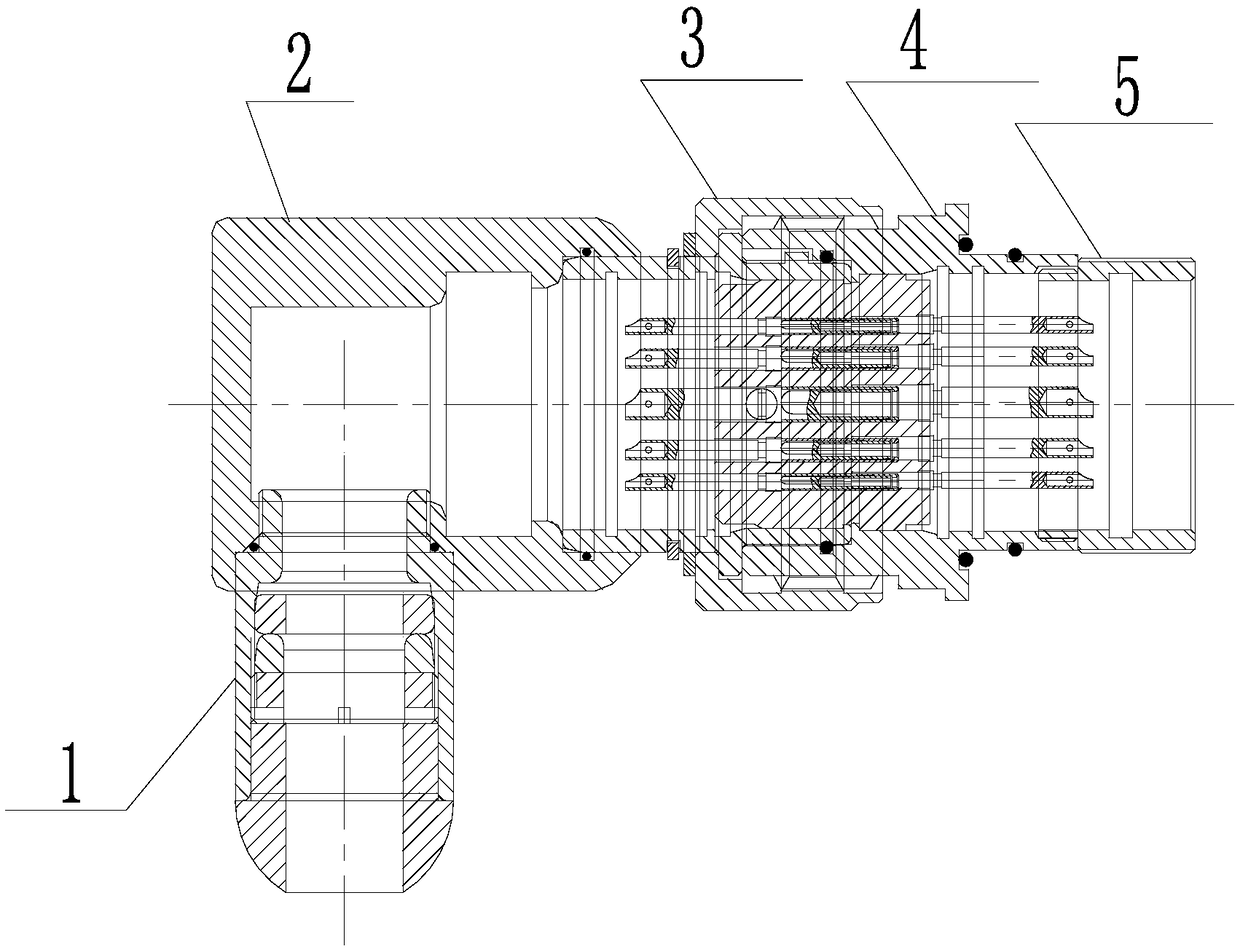

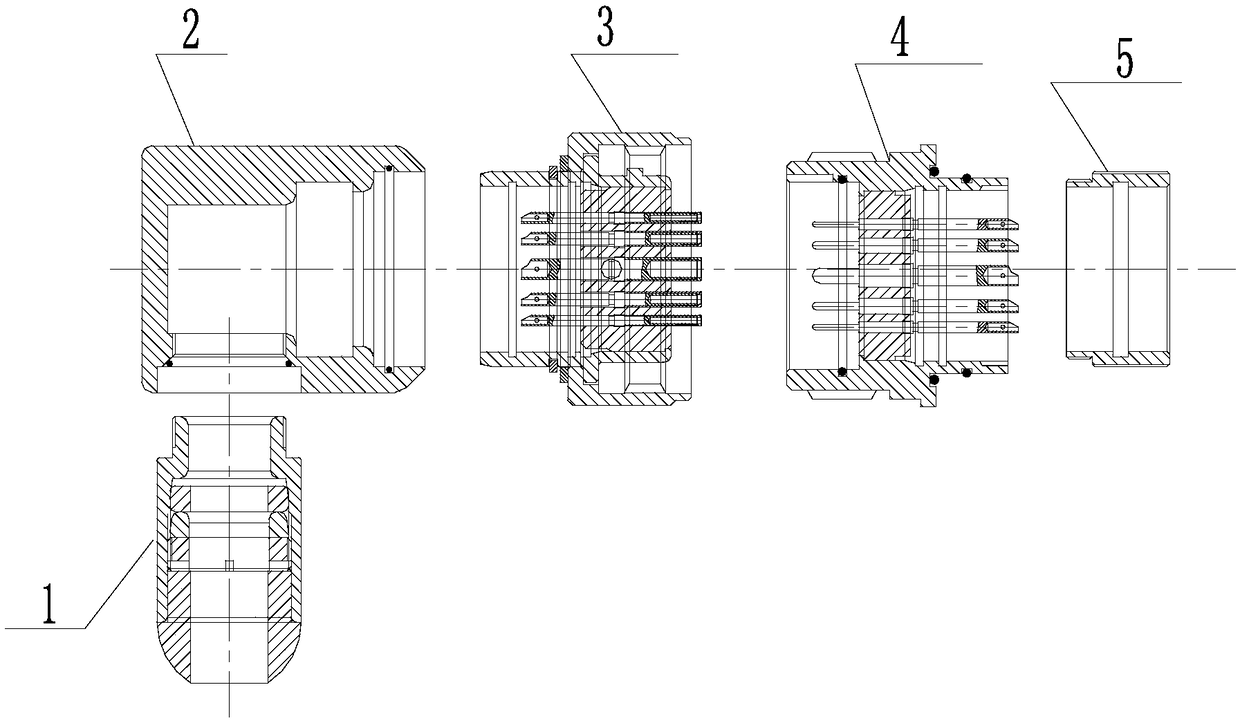

[0033] Such as Figure 1-10 As shown, the metal shell watertight connector includes a grommet assembly 1, a grommet assembly 2, a socket female assembly 3, a pin assembly 4 and a pin reinforcement assembly 5, and the grommet assembly 2 is closed at the left end, and the right end An open hollow cylinder structure, and the outer wall of the hollow cylinder structure is provided with an installation through hole 6, the grommet assembly 1 is installed in the installation through hole 6, and the right end of the grommet assembly 2 is connected to the female socket assembly 3, the socket female assembly 3 is connected to the pin assembly 4, and the pin assembly 4 is connected to the pin reinforcement assembly 5.

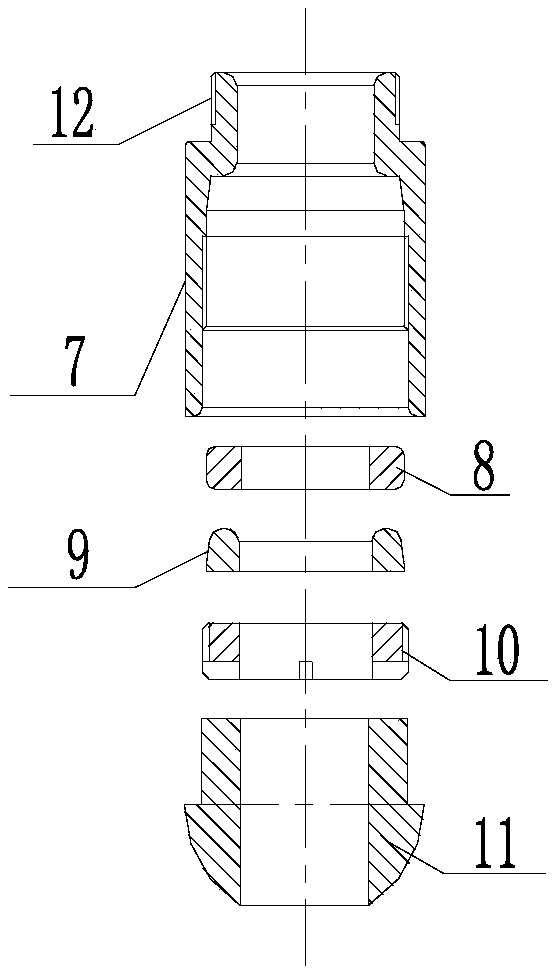

[0034] The grommet assembly 1 includes a grommet connecting sleeve 7, a compression soft washer 8, a conical hard washer 9, a set screw 10 and a mushroom-shaped grommet 11. The grommet connecting sleeve 7 is a hollow structure, so The upper middle part of the protective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com