Industrialized circulating-water culture pond water-level control and sewage discharging integrated device

A technology of circulating aquaculture and water level control, which is applied in fish farming, application, animal husbandry, etc., can solve the problems of high cost of aquaculture pipes and ditches, energy consumption, and high cost, and reduce the cost of pipes and ditches and manual operation costs Reduction, the effect of material cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

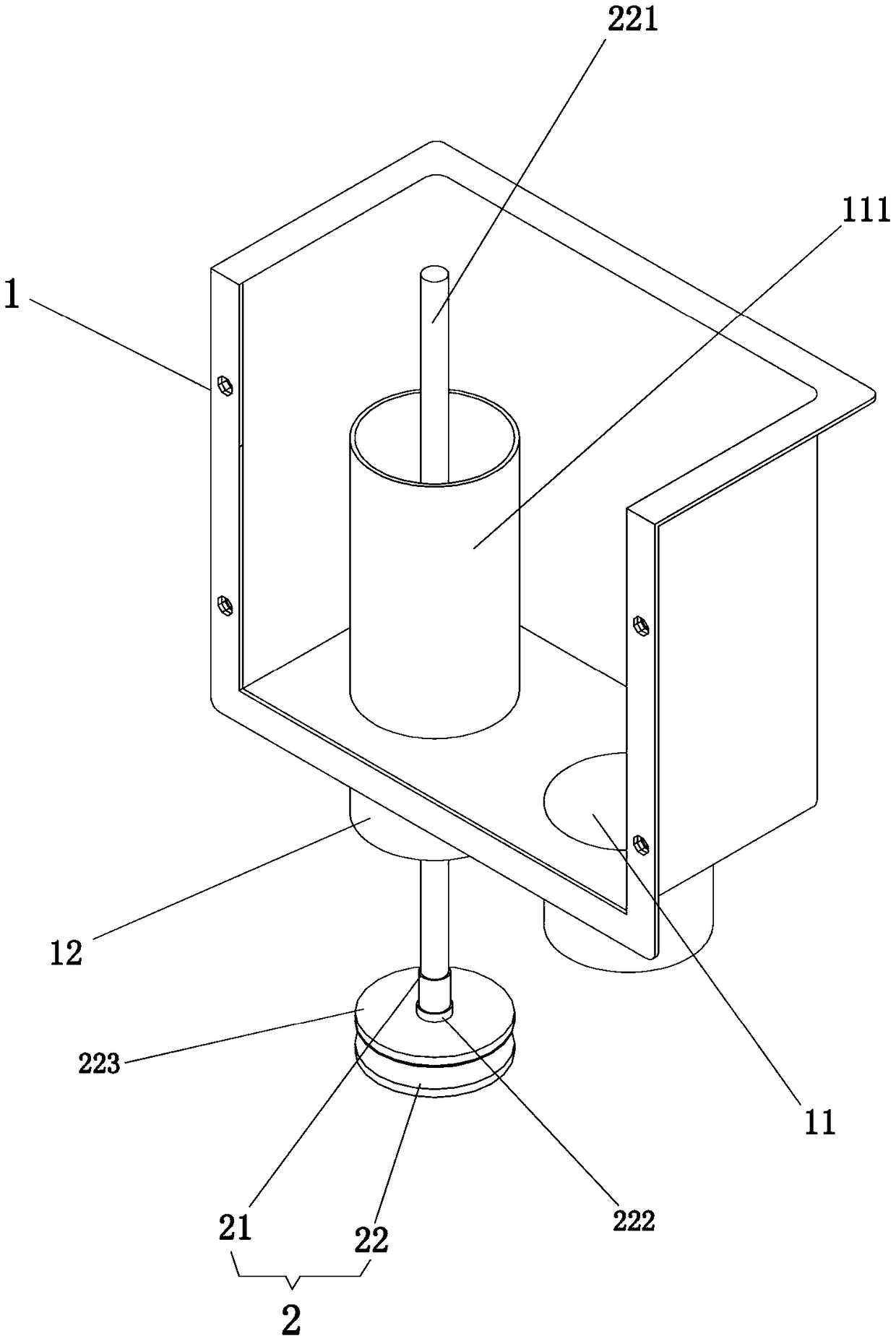

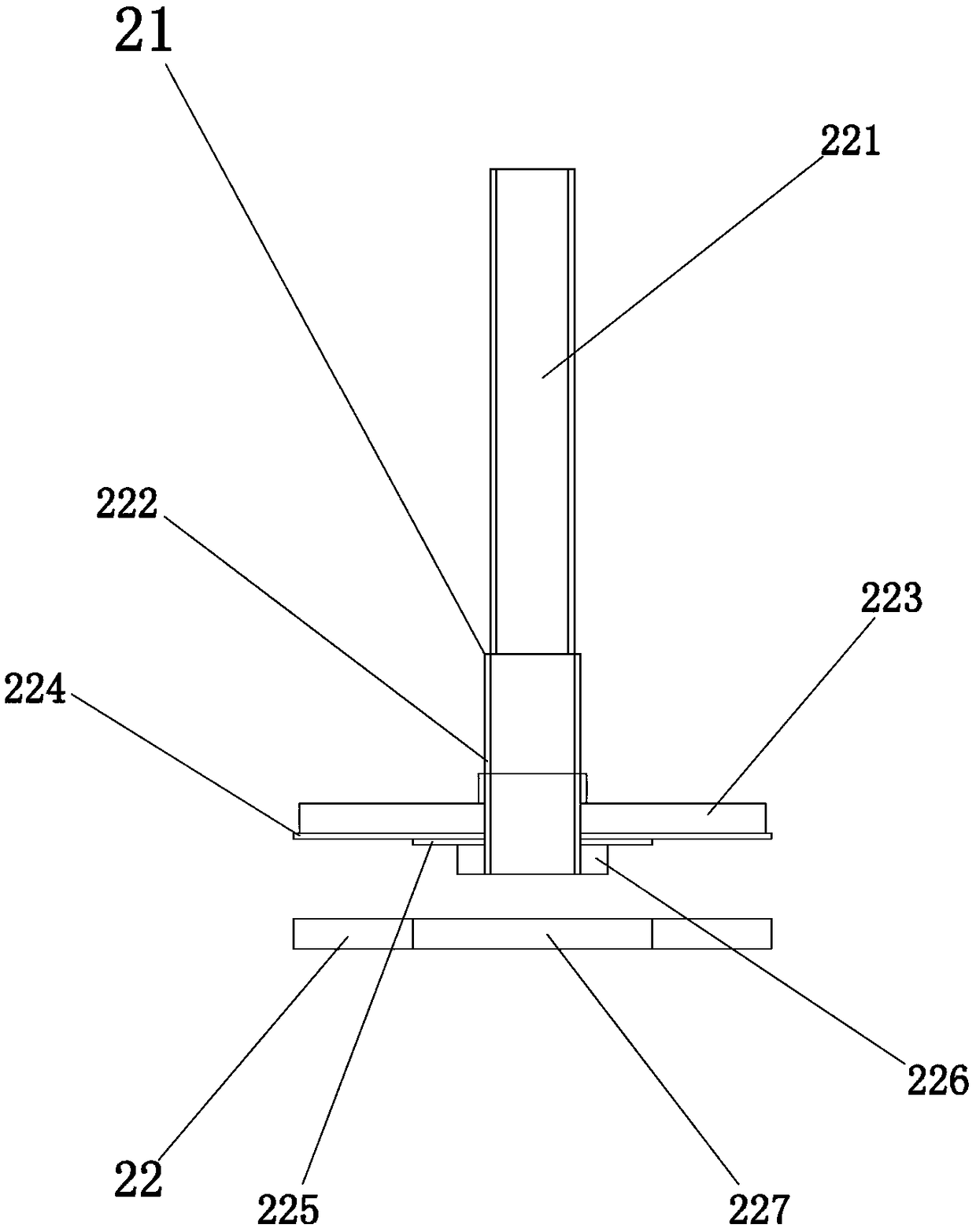

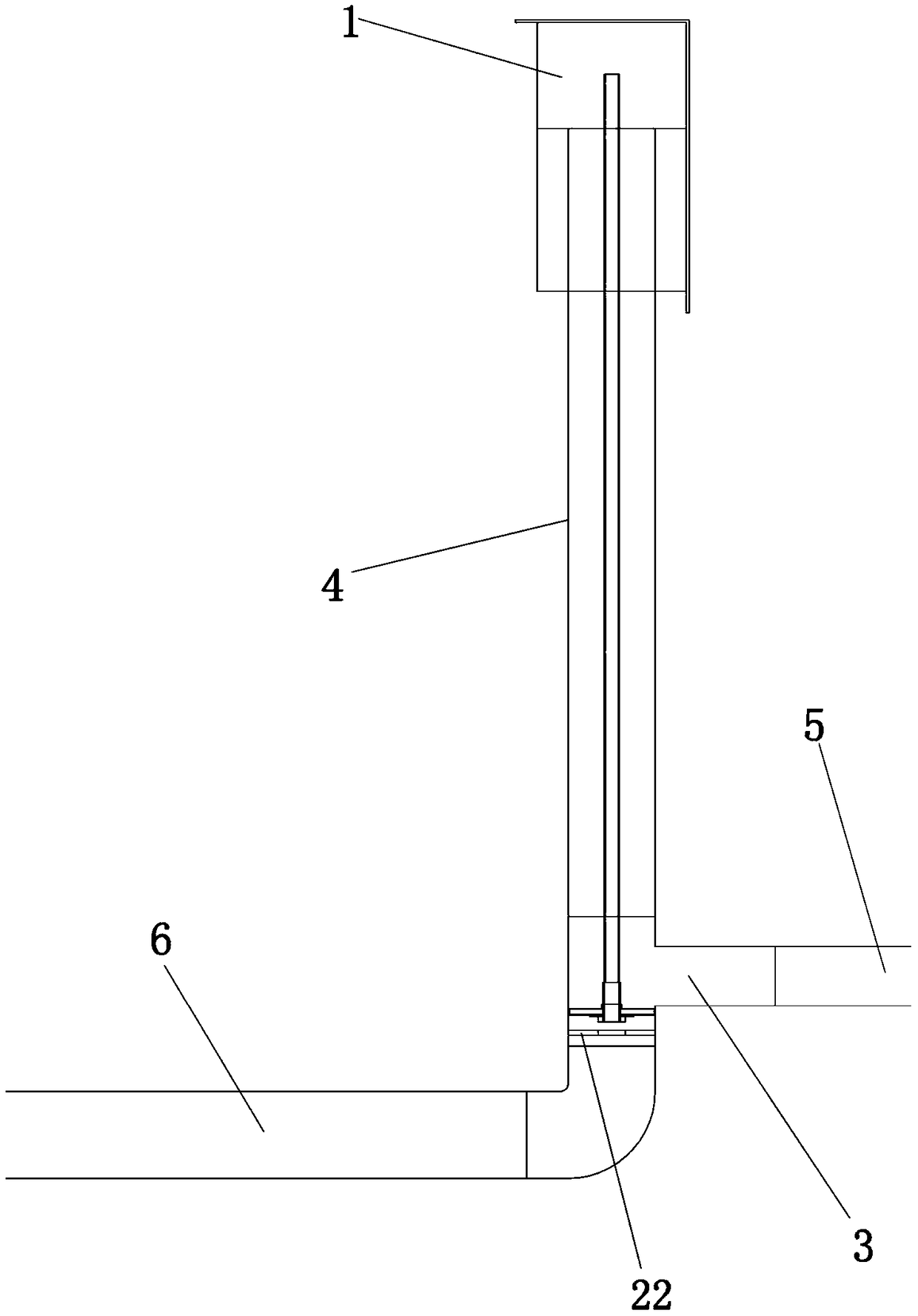

[0025] An integrated device for water level control and sewage discharge of industrial circulating water aquaculture ponds, such as figure 1 , figure 2 , image 3 As shown, it includes a water tank body 1 located on the side wall of the culture pond, and the water tank body 1 is made of glass fiber reinforced plastic or PP or PE material; the top of the water tank body 1 is flush with the surface of the side wall of the culture pond; The inner bottom of 1 is provided with a water inlet 12 and a water outlet 11; the bottom end of the water outlet 11 is connected with the main return pipe of the culture pond through a pipeline; Joint 3, the other two connecting ends of the three-way joint 3 communicate with the sewage pipe 6 and the main drain pipe 5 at the bottom of the culture pond respectively; the water inlet 12 is provided with a plug-in mechanism 2 for the water inlet 12 On-off with the drain pipe 5; the plug-in mechanism 2 includes a plug body 21 and a fixed plate 22, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com