Press of gun barrel air guide hoop

A technology for press-fitting machines and gun barrels, which is applied in the direction of workpiece clamping devices, metal processing, metal processing equipment, etc. It can solve problems such as difficult insertion, high labor intensity, and deformation of gun barrels, so as to achieve uniform clamping force and reduce labor costs. Strength, the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

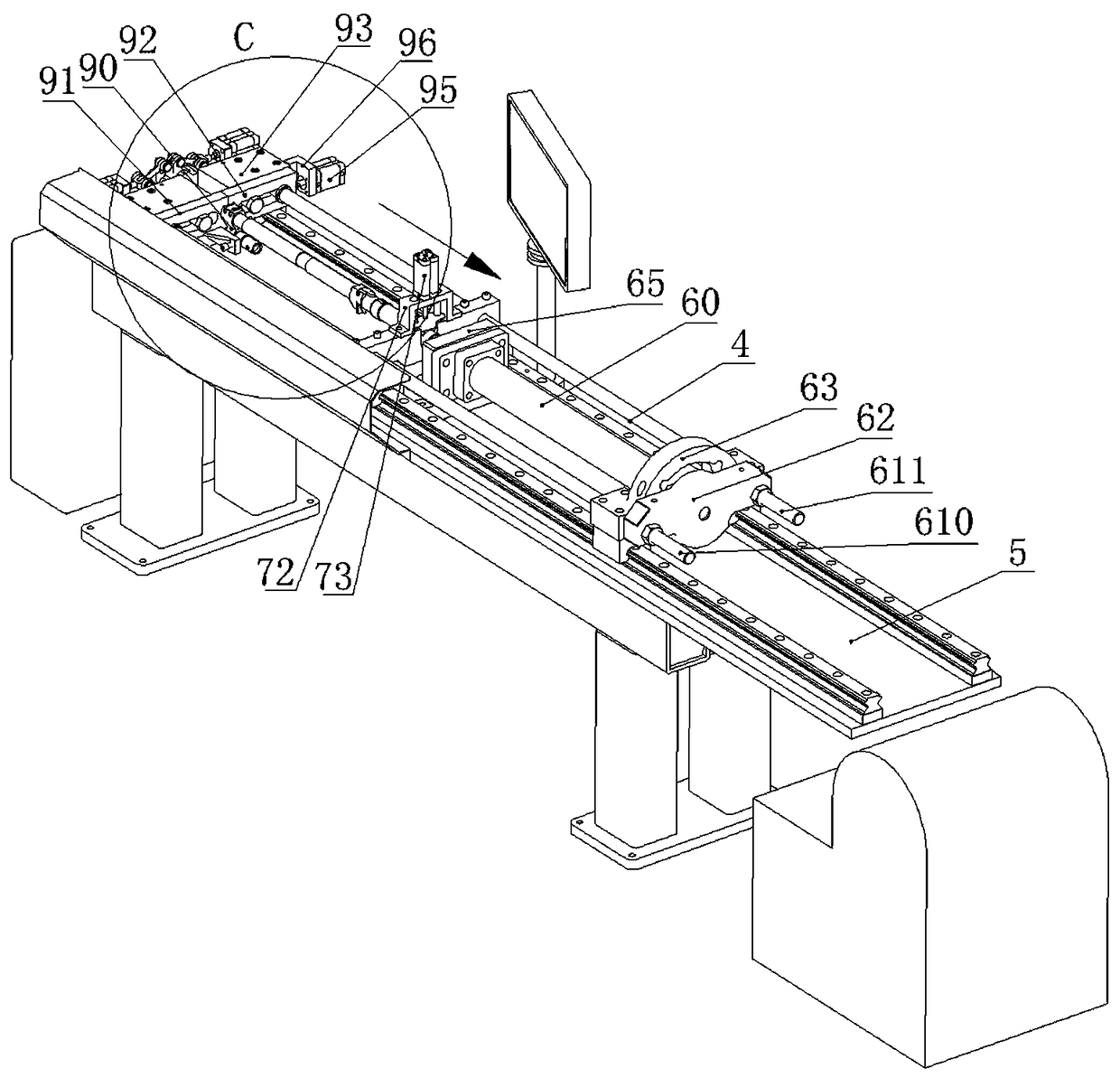

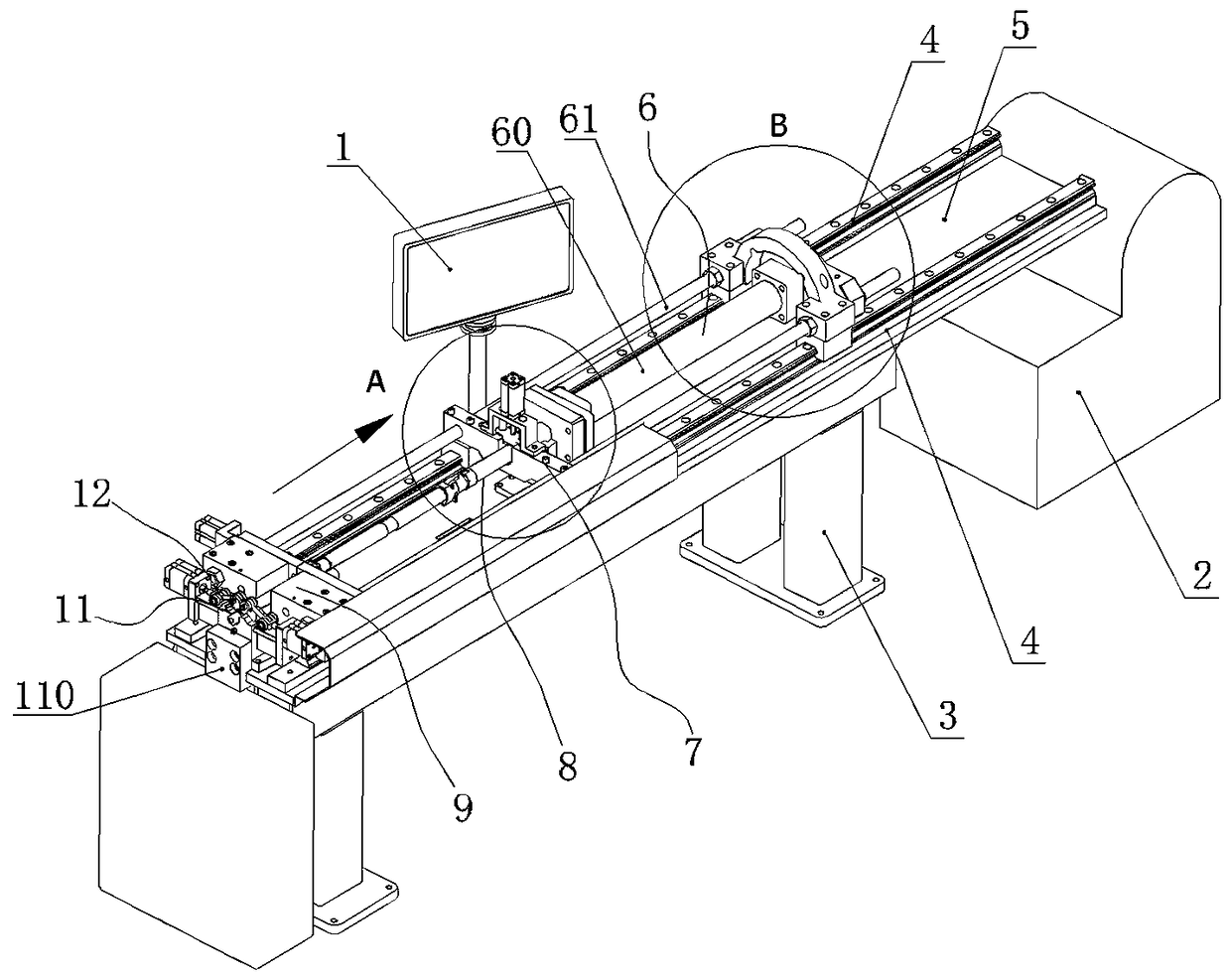

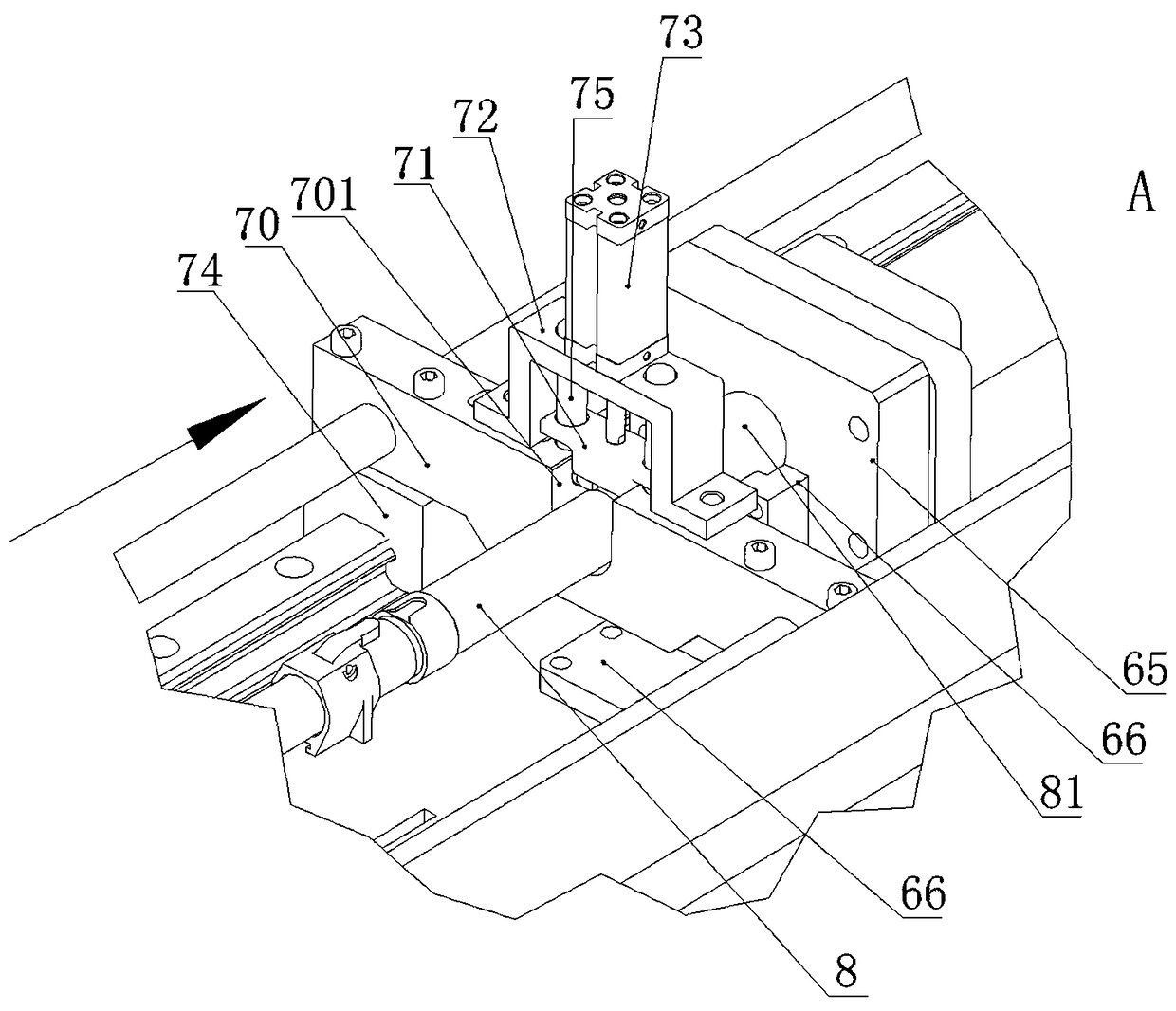

[0039] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments. Extend forward, indicated by the arrow in the figure.

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 The gas block press-fitting machine for the gun barrel shown, its device includes a control cabinet, a control panel 1, a power source 2, a support base 3, a guide rail 4, a guide rail base 5, a power press-fit assembly 6, and a barrel rear positioning assembly 7. The front positioning tooling 11 of the gas block positioning assembly 9 and the gun barrel, the support base 3 supports the guide rail base 5, and the guide rails 4 are two horizontally placed side by side, and are installed in parallel along the front and rear directions of the guide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com