Special tool for detaching anti-loose lock sheet

A special tool and locking plate technology, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problem of indentation on the workpiece, and achieve the effect of reducing friction, reducing operation difficulty, and smooth and labor-saving rotation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

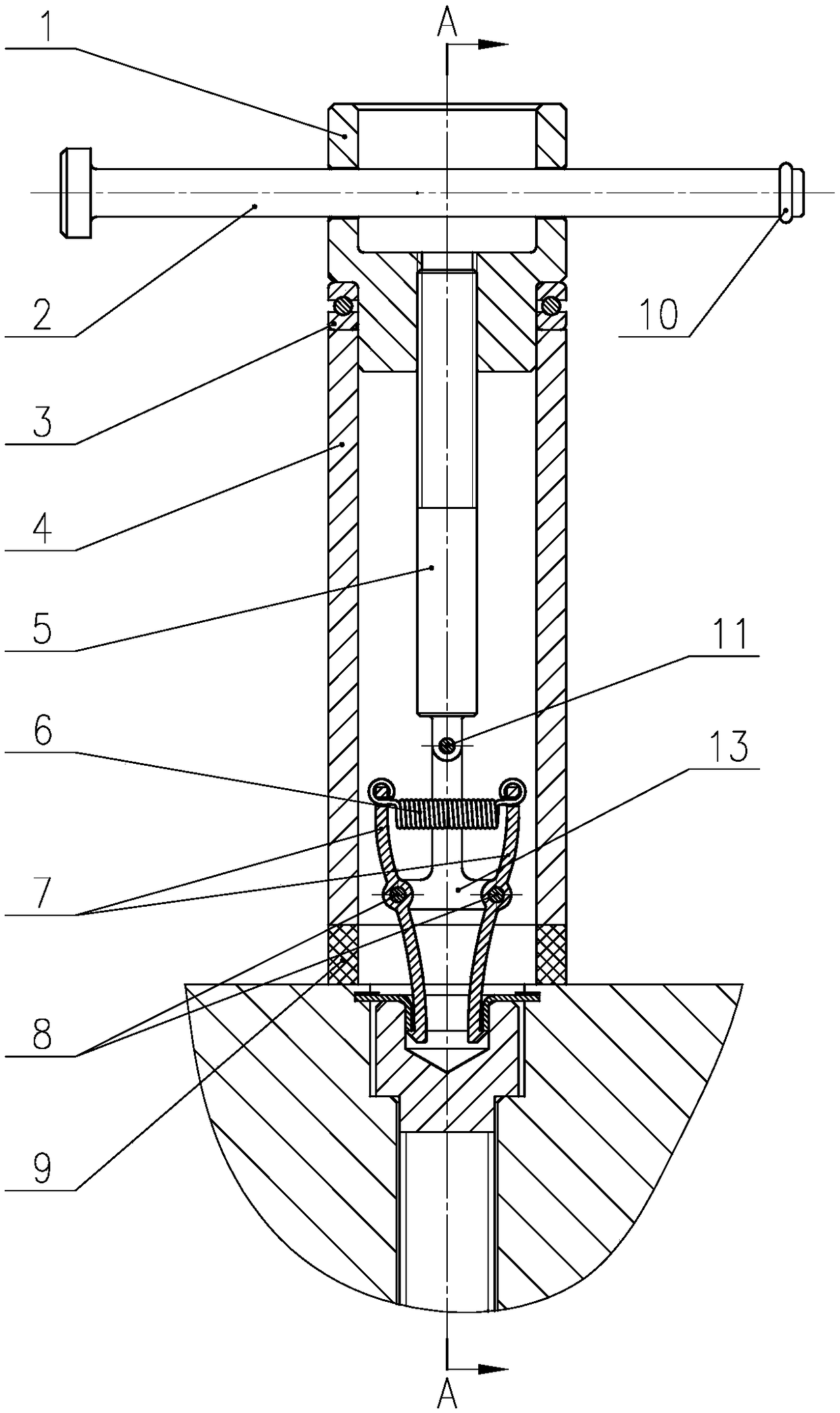

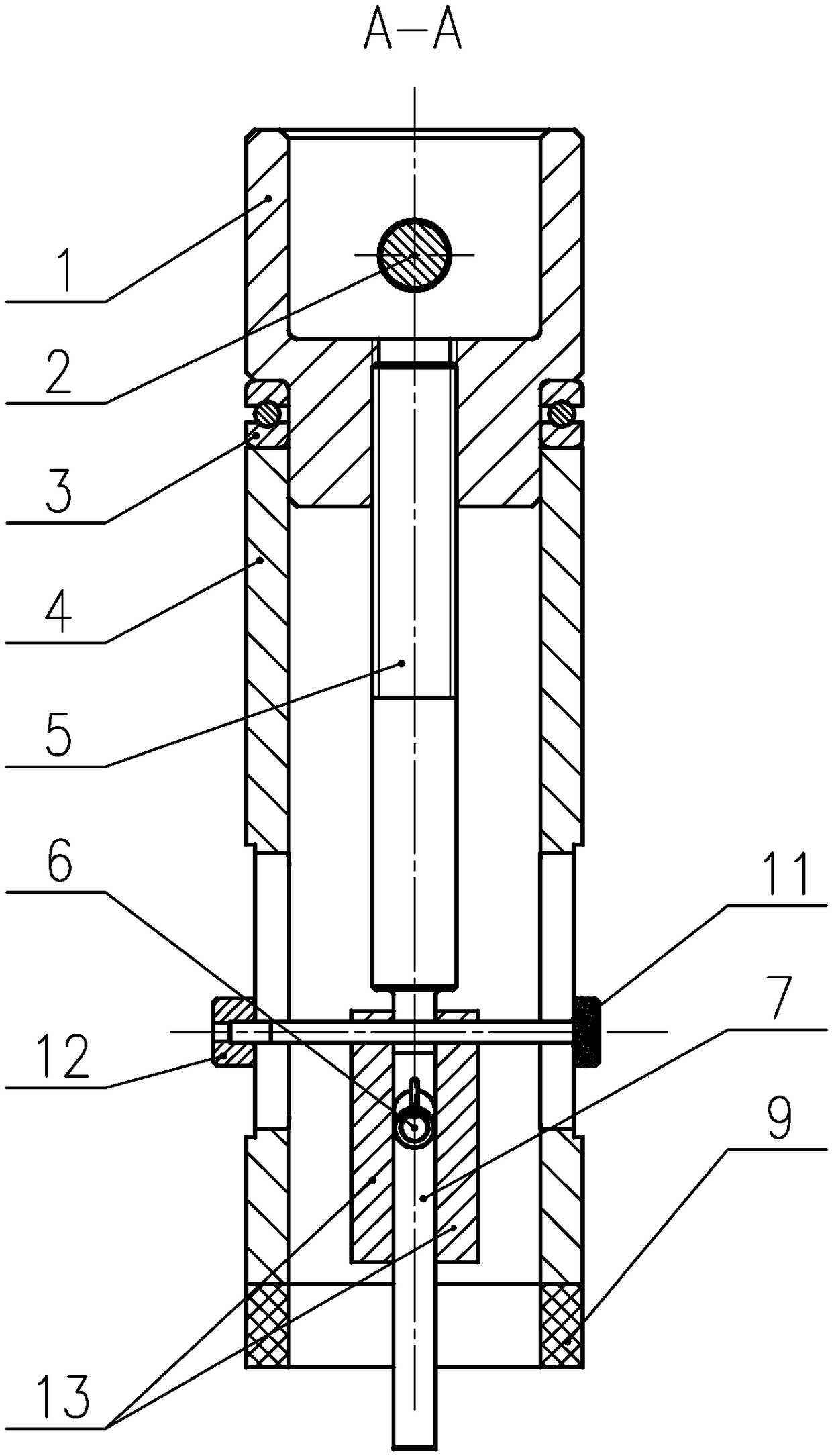

[0012] Such as figure 1 As shown, a special tool for removing the anti-loosening lock piece, the hook 7 is hinged with the T-shaped connector 13 through the pin 8, and the tension spring 6 is installed in the round hole opened at the upper end of the two hooks 7; the T-shaped connector 13 is fixedly connected with the lifting screw 5 through the connecting screw 11; the lifting screw 5 is threadedly connected with the end nut 1; the wrench 2 is installed in the two round holes opened on the end nut 1, and the O-ring 10 is installed in the groove at one end of the wrench 2 Backing plate 9 is pasted and fixed on the lower end of sleeve 4; Nut 12 is threadedly connected with connecting screw 11, as figure 2 shown.

[0013] Such as figure 2 Shown, the waist-shaped hole that its side wall of sleeve 4 offers installs connecting screw 11.

[0014] The assembly that extension spring 6, hook claw 7, pin 8 and T-shaped connector 13 forms can be replaced in a complete set. During ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com