Scotch block jack for passenger train garage and passenger station of railway

A technology for railway passenger cars and passenger technical stations, which is applied in the direction of railway car body components, railway braking systems, and brakes that interact with brake components and rails. Foundation and other problems, to achieve the effect of long return time, increase traction efficiency and reduce failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

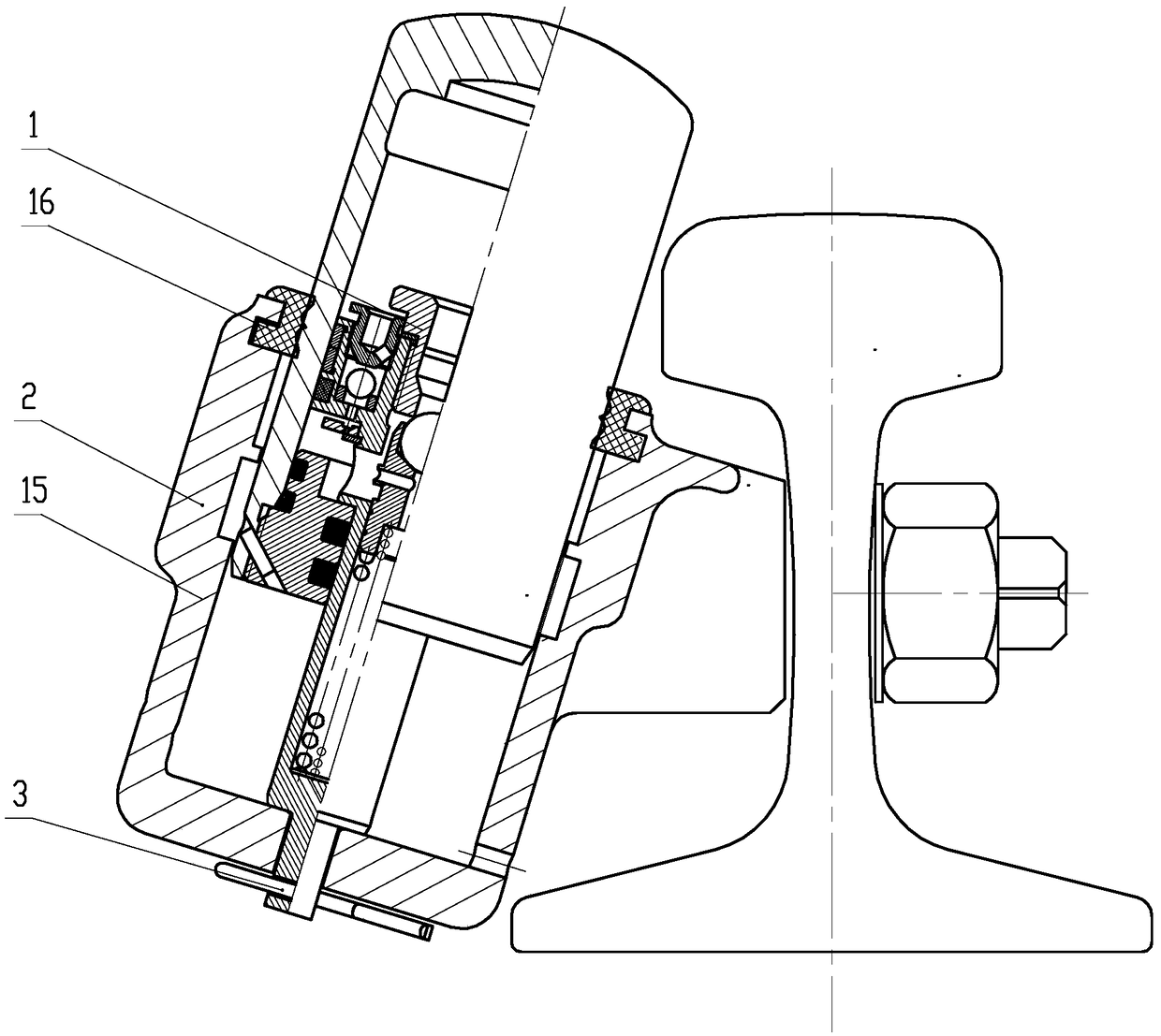

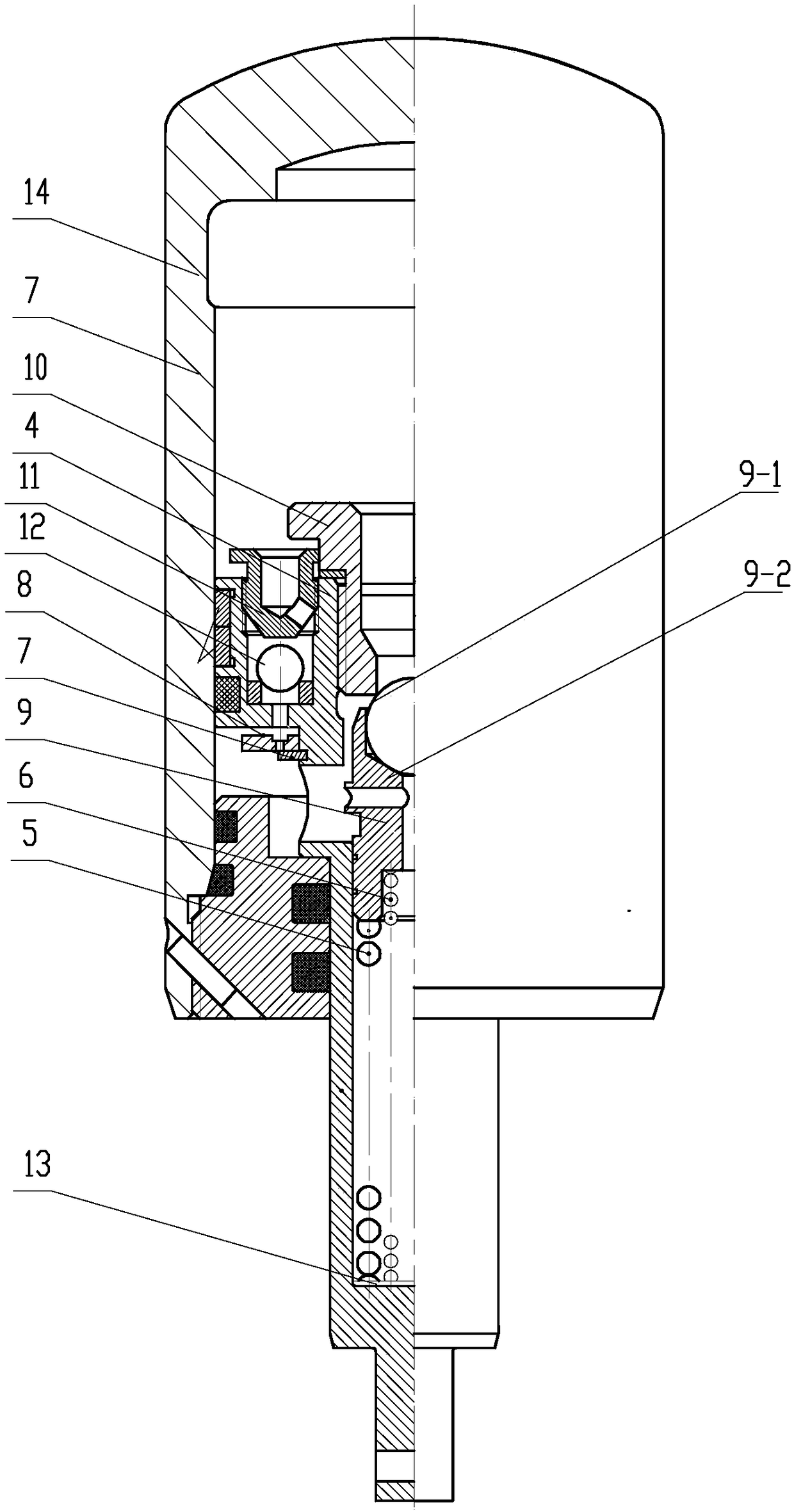

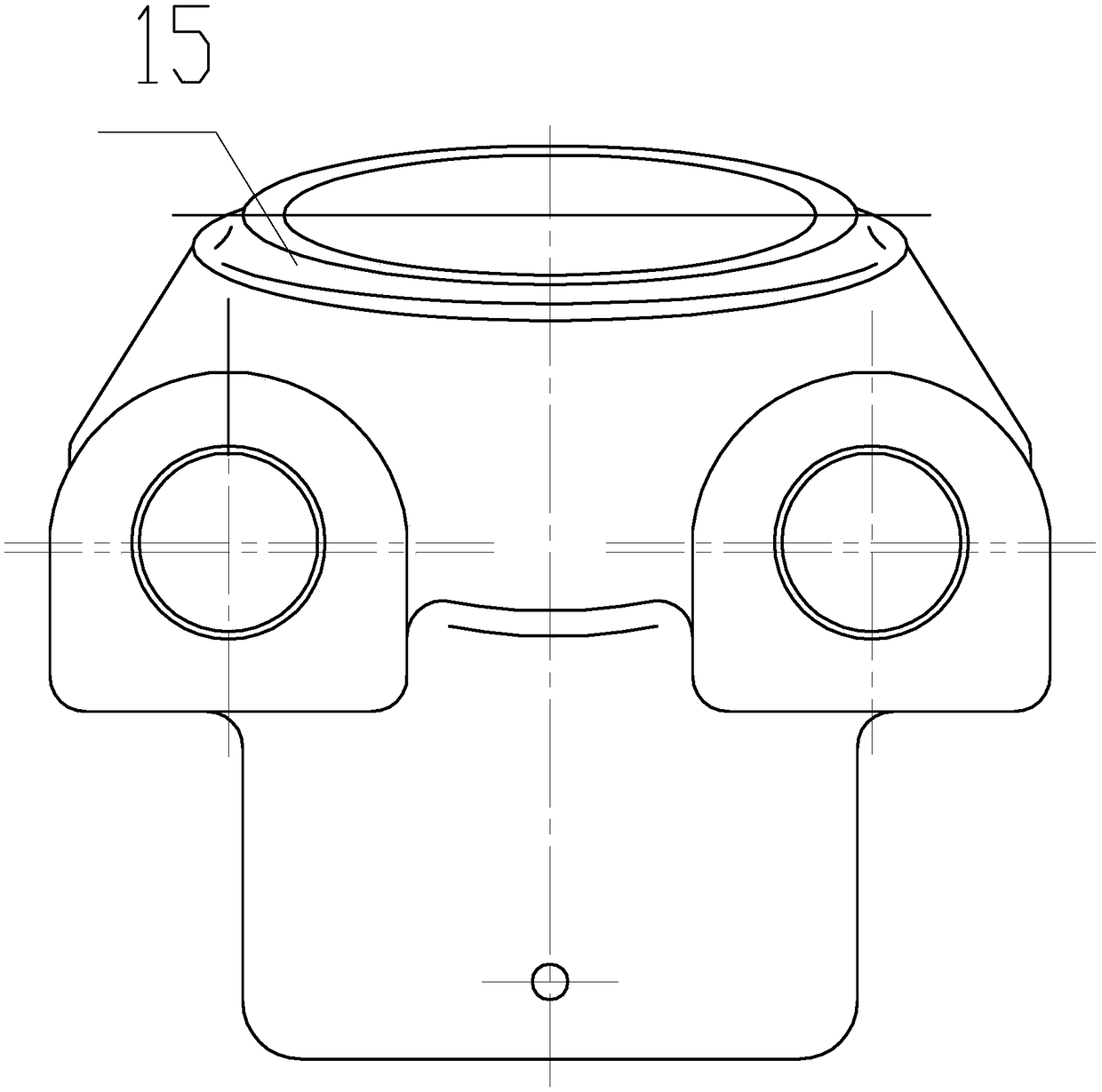

[0020] Specific implementation mode one: combine Figure 1-Figure 5 Describe this embodiment mode, a kind of wheel stop top that is used for railway passenger depot, passenger technology station described in this embodiment mode, it comprises housing assembly 2, slide oil cylinder assembly 1 and anti-shock structure 3; Slide oil cylinder assembly 1 Including piston rod 4, pressure valve outer spring 5, pressure valve inner spring 6, circlip 7, return valve plate 8, pressure valve stem 9, pressure valve seat 10, check valve adjusting screw 11, check valve steel ball 12, Sliding oil cylinder 14 and sealing assembly; the top of the piston rod 4 is processed with a spring installation blind hole, the pressure valve outer spring 5 and the pressure valve inner spring 6 are set in the spring installation blind hole of the piston rod 4, and the pressure valve outer spring 5 is set in the On the inner spring 6 of the pressure valve, the pressure valve stem 9 is arranged in the spring i...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination figure 1 Describe this embodiment, a kind of wheel stop top that is used for railway passenger garage, passenger technology station described in this embodiment, stop impact structure 3 is cotter pin or R pin, and cotter pin or R pin is inserted in the bottom end of piston rod 4 On the connecting column, the others are the same as those in Embodiment 1.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, the wheel stopper used for railway passenger garages and passenger technical stations described in this embodiment, the sliding cylinder assembly 1 also includes a pressure adjustment pad 13, and the pressure adjustment pad 13 is arranged at the bottom of the spring installation blind hole On the end, the bottom ends of the pressure valve outer spring 5 and the pressure valve inner spring 6 bear on the pressure adjustment pad 13 . Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com