Bent rail elevator lifting rack

A technology of curved track and elevator frame, which is applied in elevators, elevators in buildings, vertical pipelines, etc., which can solve the problem of high cost of rust prevention and maintenance of the steel structure of the hoistway, without consideration of the installation of elevators, civil engineering, and long installation periods, etc. To solve the problem, to achieve the effect of saving steel structure parts and curtain walls, eliminating the need for counterweight devices, saving production costs and installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

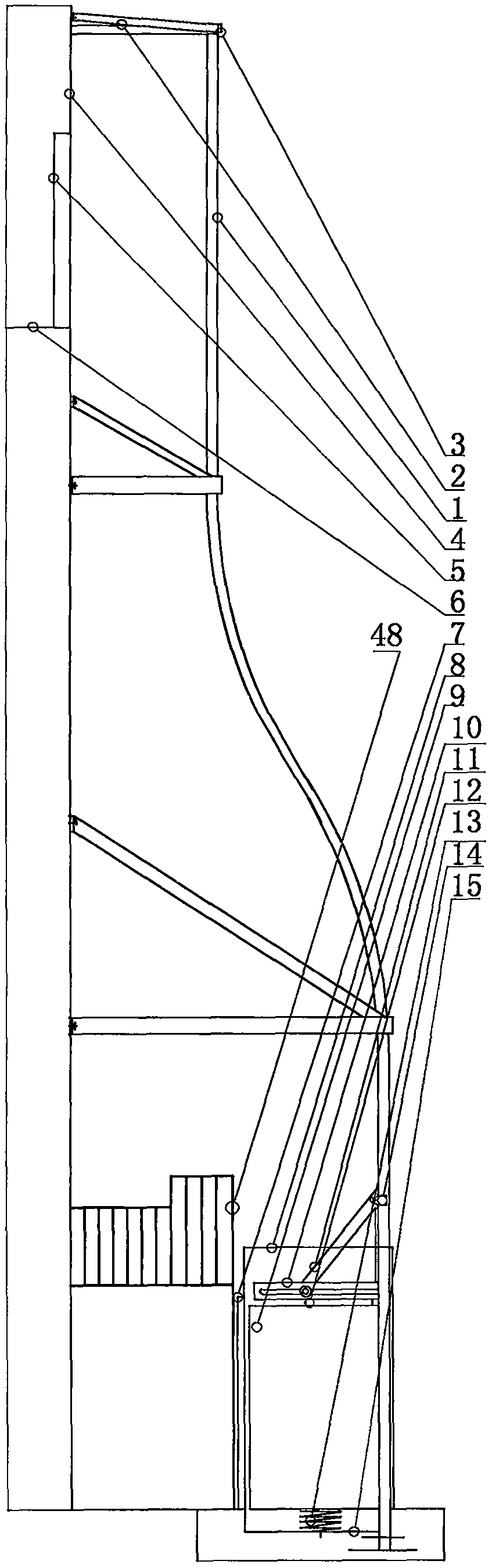

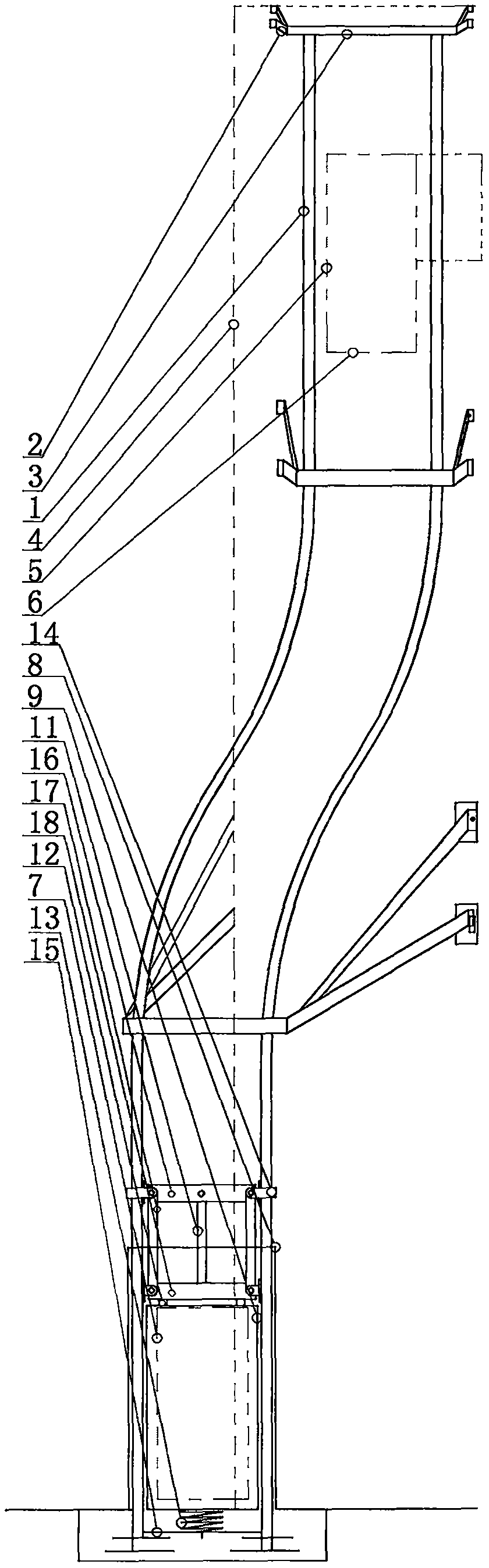

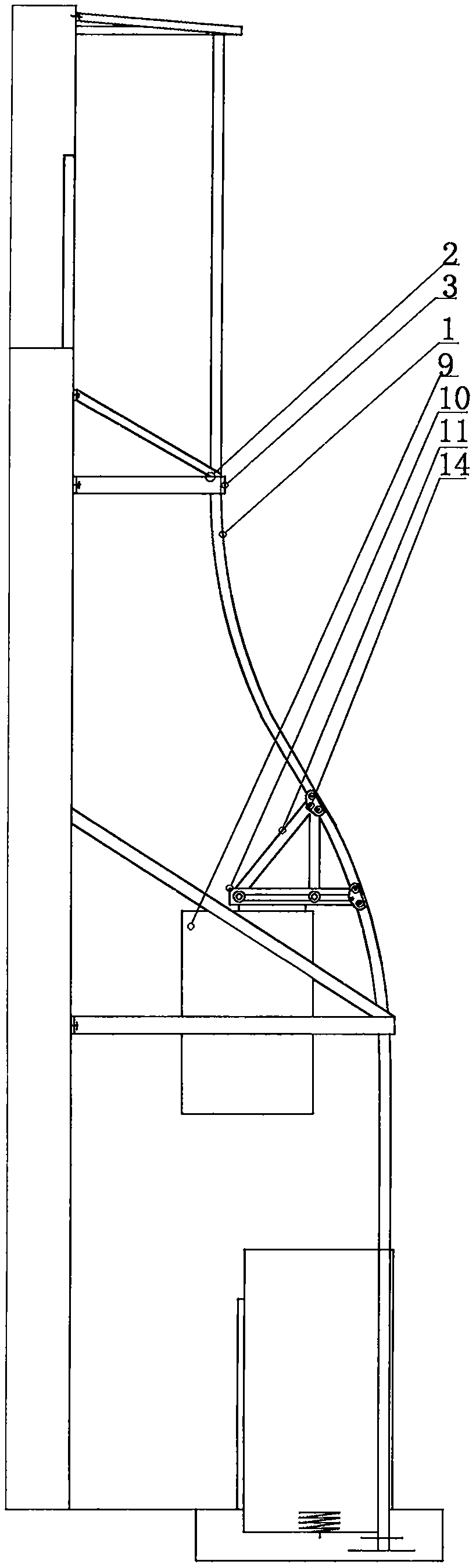

[0038] The specific implementation manners of the present application will be further described below in conjunction with the accompanying drawings.

[0039]In the figure, it includes curved track 1, transverse brace 2, track distance rod 3, corridor wall 4, corridor elevator door 5, corridor 6, elevator door 7, elevator cover 8, car box 9, leveling frame 10, and leveling angle 11. Balance contact 12, buffer spring 13, lateral positioning wheel 14, car pit 15, active beam device 16, boom 17, passive beam device 18, boom groove 19, longitudinal positioning wheel 20, gear 21, rack 22. Gear shaft 23, leveling ear 24, worm motor 25, frequency converter 26, power supply slide bar 27, power supply chute 28, synchronous stopper 29, pulley groove 30, leveling screw seat 31, leveling motor 32, Screw rod 33, leveling car 34, leveling buckle 35, connecting ear 36, pulley 37, car seat 38, car shaft 39, leveling spring 40, waterproof dustproof cover 41, waterproof soft board 42, power supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com