A kind of pet waste fiber/bamboo fiber reinforced styrene-free soybean oil-based resin composite material

A soybean oil-based resin and styrene-free technology, which is applied in the field of fiber-reinforced resin composite materials, can solve the problems of poor heat resistance, high viscosity, and low crosslinking degree of epoxy soybean oil acrylate, so as to achieve reduced use and good pull The effect of stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

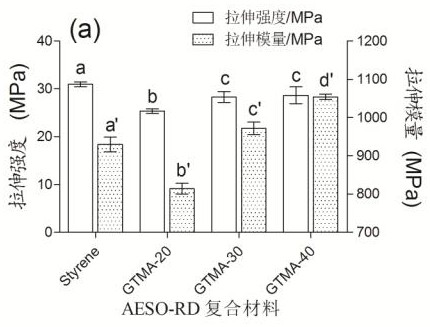

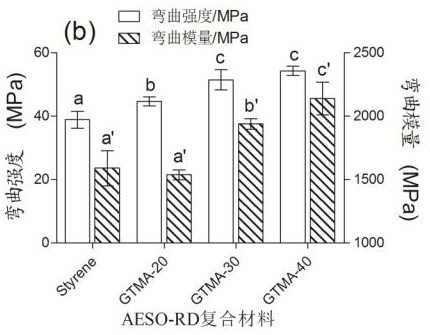

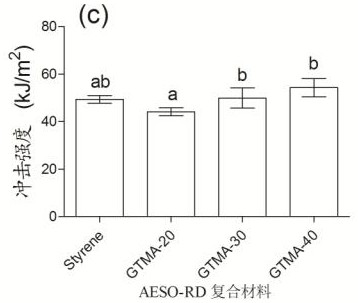

[0022] PET waste fiber / bamboo fiber reinforced soybean oil-based resin composite material:

[0023] The preparation process of soybean oil-based resin is as follows: soybean oil derivatives (42 g) and crosslinking agent (18 g) are placed in a round bottom flask, and stirred with a magnetic stirrer at room temperature for 5 minutes to obtain a soybean oil-based resin mixture; The soybean oil derivative is AESO; the crosslinking agent is GTMA; the initiator is TBPB.

[0024] Composite material preparation method: Weigh 60g of soybean oil-based resin mixture and 1.2g of TBPB, mix and stir for 3 minutes with a glass rod. Take the dried fiber felt out of the oven, wrap it in a plastic airtight bag, and when it is cooled to room temperature, 2 pieces of PET waste fiber / bamboo fiber fiber felt (60g) are laminated and arranged in the orthogonal direction to form a fiber slab. Uniformly mixed soybean oil-based resin and additives are evenly coated on both surfaces of the fiber mat, th...

Embodiment 2

[0027] PET waste fiber / bamboo fiber reinforced soybean oil-based resin composite material:

[0028] The preparation process of soybean oil-based resin is as follows: soybean oil derivatives (48g) and cross-linking agent (12g) are placed in a round bottom flask, and stirred with a magnetic stirrer at room temperature for 5 minutes to obtain a soybean oil-based resin mixture; The soybean oil derivative is AESO; the crosslinking agent is GTMA; the initiator is TBPB.

[0029] Composite material preparation method: Weigh 60g of soybean oil-based resin mixture and 1.2g of TBPB, mix and stir for 3 minutes with a glass rod. Take the dried fiber felt out of the oven, wrap it in a plastic airtight bag, and when it is cooled to room temperature, 2 pieces of PET waste fiber / bamboo fiber fiber felt (60g) are laminated and arranged in the orthogonal direction to form a fiber slab. Uniformly mixed soybean oil-based resin and additives are evenly coated on both surfaces of the fiber mat, then ...

Embodiment 3

[0032] PET waste fiber / bamboo fiber reinforced soybean oil-based resin composite material:

[0033] The preparation process of soybean oil-based resin is as follows: soybean oil derivatives (36g) and cross-linking agent (24g) are placed in a round bottom flask, and stirred with a magnetic stirrer at room temperature for 5 minutes to obtain a soybean oil-based resin mixture; The soybean oil derivative is AESO; the crosslinking agent is GTMA; the initiator is TBPB.

[0034] Composite material preparation method: Weigh 60g of soybean oil-based resin mixture and 1.2g of TBPB, mix and stir for 3 minutes with a glass rod. Take the dried fiber felt out of the oven, wrap it in a plastic airtight bag, and when it is cooled to room temperature, 2 pieces of PET waste fiber / bamboo fiber fiber felt (60g) are laminated and arranged in the orthogonal direction to form a fiber slab. Uniformly mixed soybean oil-based resin and additives are evenly coated on both surfaces of the fiber slab, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com