Basalt scale corrosion-resistant wave-absorbing paint and preparation method thereof

A technology of wave absorbing paint and basalt, applied in the field of paint and wave absorbing paint, can solve the problems of low mechanical strength of glass flakes, insufficient acid and alkali resistance, insufficient wear resistance, etc., and achieve excellent physical and chemical properties and mechanical properties, anti-corrosion properties. Outstanding performance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

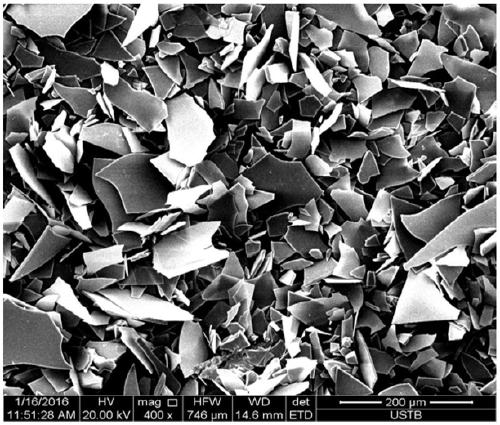

[0020] Mix basalt flakes, flaky sendust powder and polyurethane resin at a mass ratio of 0.2:0.4:1, stir thoroughly for 10 minutes, and add diluent (ethyl acetate: butyl acetate volume ratio =1:1 composition), followed by mechanical stirring at a speed of 480 rpm for 30 minutes, and the resulting mixed solution was placed in an ultrasonic oscillator for 30 minutes to obtain a uniformly mixed solution. Then add the polyurethane curing agent according to the mass ratio of 0.3 to the polyurethane resin, and then repeat the above mechanical stirring and ultrasonic vibration for 30 minutes each to obtain the wave-absorbing coating. Such as figure 1 As shown, the added basalt scales are flakes of 10 microns to 200 microns, with a thickness of 0.8 microns to 6 microns.

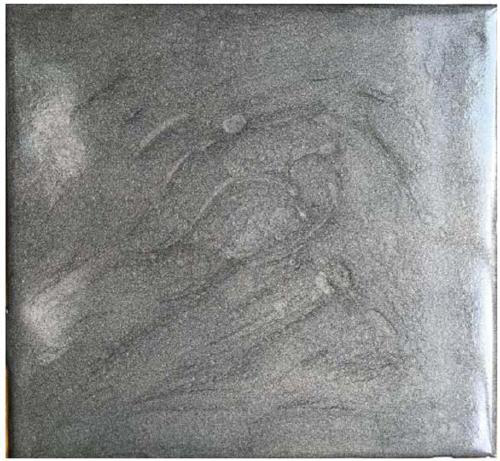

[0021] The prepared coating was injected into the prepared mold, coated on a 200 mm × 200 mm Al plate, and the thickness of the coating was controlled to be 1.5 mm through the mold. Finally, it is naturally cured a...

Embodiment 2

[0024] Mix basalt flakes, flaky sendust powder and polyurethane resin at a mass ratio of 0.4:0.4:1, stir thoroughly for 20 minutes, and add diluent (ethyl acetate: butyl acetate volume ratio =1:1 composition), followed by mechanical stirring at a speed of 480 rpm for 60 minutes, and the resulting mixed solution was placed in an ultrasonic oscillator for 30 minutes to obtain a uniformly mixed solution. Then add the polyurethane curing agent according to the mass ratio of 0.3 to the polyurethane resin, and then repeat the above mechanical stirring and ultrasonic vibration for 30 minutes each to obtain the wave-absorbing coating.

[0025] The prepared coating was injected into the prepared mold, coated on a 200 mm × 200 mm Al plate, and the thickness of the coating was controlled to be 1.5 mm through the mold. Finally, it is naturally cured and formed at room temperature. After curing and formed, the sample is demoulded for trimming and performance testing.

[0026] The electrom...

Embodiment 3

[0028] Mix basalt flakes, flaky sendust powder and epoxy resin at a mass ratio of 0.5:0.5:1, stir thoroughly for 40 minutes, and add diluent (n-butanol:xylene volume Ratio = 1:1 composition), followed by mechanical stirring at a speed of 500 rpm for 40 minutes, and the resulting mixed solution was placed in an ultrasonic oscillator for 30 minutes to obtain a uniformly mixed solution. Then, after adding the curing agent hexamethylenediamine in a ratio of 0.5 to the mass ratio of the epoxy resin, repeat the above mechanical stirring and ultrasonic vibration for 20 minutes each to obtain the wave-absorbing coating.

[0029] The prepared coating was injected into the prepared mold, coated on a 200 mm × 200 mm Al plate, and the thickness of the coating was controlled to be 1.5 mm through the mold. Finally, it is naturally cured and formed at room temperature. After curing and formed, the sample is demoulded for trimming and performance testing.

[0030]The electromagnetic wave abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com