Device and method for preparing a pair of double-sided jacquard full formed 3D elastic bionic hair products

A hair product and 3D technology, which is applied in the field of paired preparation equipment for double-sided jacquard full-form 3D elastic bionic hair products, can solve problems such as unfavorable development and increased use costs, and achieve good wearability, excellent elasticity, and beautiful hairstyles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

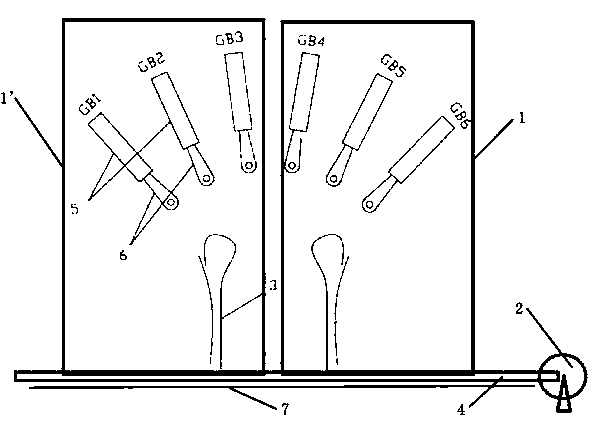

[0018] Such as figure 1 As shown, the double-sided jacquard fully formed 3D elastic bionic hair products paired preparation equipment includes a jacquard warp knitting machine, a hair bionic fixed-length cutting device and a frame moving device, and the front and rear of the jacquard warp knitting machine The needle beds are arranged on the front frame 1 and the rear frame 1' respectively. The frame moving device includes a motor 2, a lead screw 4 and a guide rail 7. The front and rear frames are arranged on the guide rails. The spacing is adjusted along the guide rails on the frame, and the hair bionic fixed-length cutting device is arranged on the rear frame.

[0019] The method for preparing double-sided jacquard full-formed 3D elastic bionic hair products in pairs using the described preparation equipment is as follows: the front and rear racks are respectively provided with 4 combs, and a jacquard comb is used Weaving with non-elastic yarn A, weaving with elastic yarn B ...

Embodiment 2

[0022] In order to prepare jacquard pattern jacquard and hollow-out base fabric wigs, double-sided jacquard fully formed 3D elastic bionic hair products are used in pairs to prepare: according to the head shape and heat dissipation requirements, a customized pattern base fabric is prepared on the top and back of the head; in order to meet For perspiration needs, jacquard and hollowing form a point contact form, and the point distribution flows to the neck for concentrated discharge. The hair bionic fixed-length cutting device intelligently adjusts the movement of the rack on the slide rail according to the fashion trend and customer needs, ensuring that the length of each comb is changed to meet customer needs and remote customization orders for 35 cm long wig headgear. The rack moving device gives the motor a motion signal to adjust the rotation of the lead screw, and the front and rear racks adjust the distance along the slide rail. The knitting motion of each part in the kn...

Embodiment 3

[0024] In order to prepare jacquard base fabric pattern jacquard and hollow base fabric wigs, double-sided jacquard fully formed 3D elastic bionic hair products are used in pairs to prepare: according to the head shape and warmth requirements, a custom-made compact pattern base fabric is prepared on the top of the head and the back of the head; To meet the thermal insulation requirements, the hollow spiral thermal insulation base fabric is directly prepared from Jacquard. The hair bionic fixed-length cutting device intelligently adjusts the movement of the rack on the slide rail according to the fashion trend and customer needs, ensuring the change of the length of the hair in each comb, meeting customer needs and remotely customizing orders for 45 cm long wig hair pieces. The rack moving device gives the motor a motion signal to adjust the rotation of the lead screw, and the front and rear racks adjust the distance along the slide rail. The knitting motion of each part in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com