System and method for measuring waste gas pressure in coke oven bridge tube

A measurement system and raw gas technology, applied in the direction of pressure difference measurement between multiple valves, measuring devices, measuring fluid pressure, etc., can solve problems such as blockage of pressure guiding pipes, overflow of raw gas, unsatisfactory effects, etc., to achieve sealing Good effect, good anti-blocking effect, and solve the effect of overheating and burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

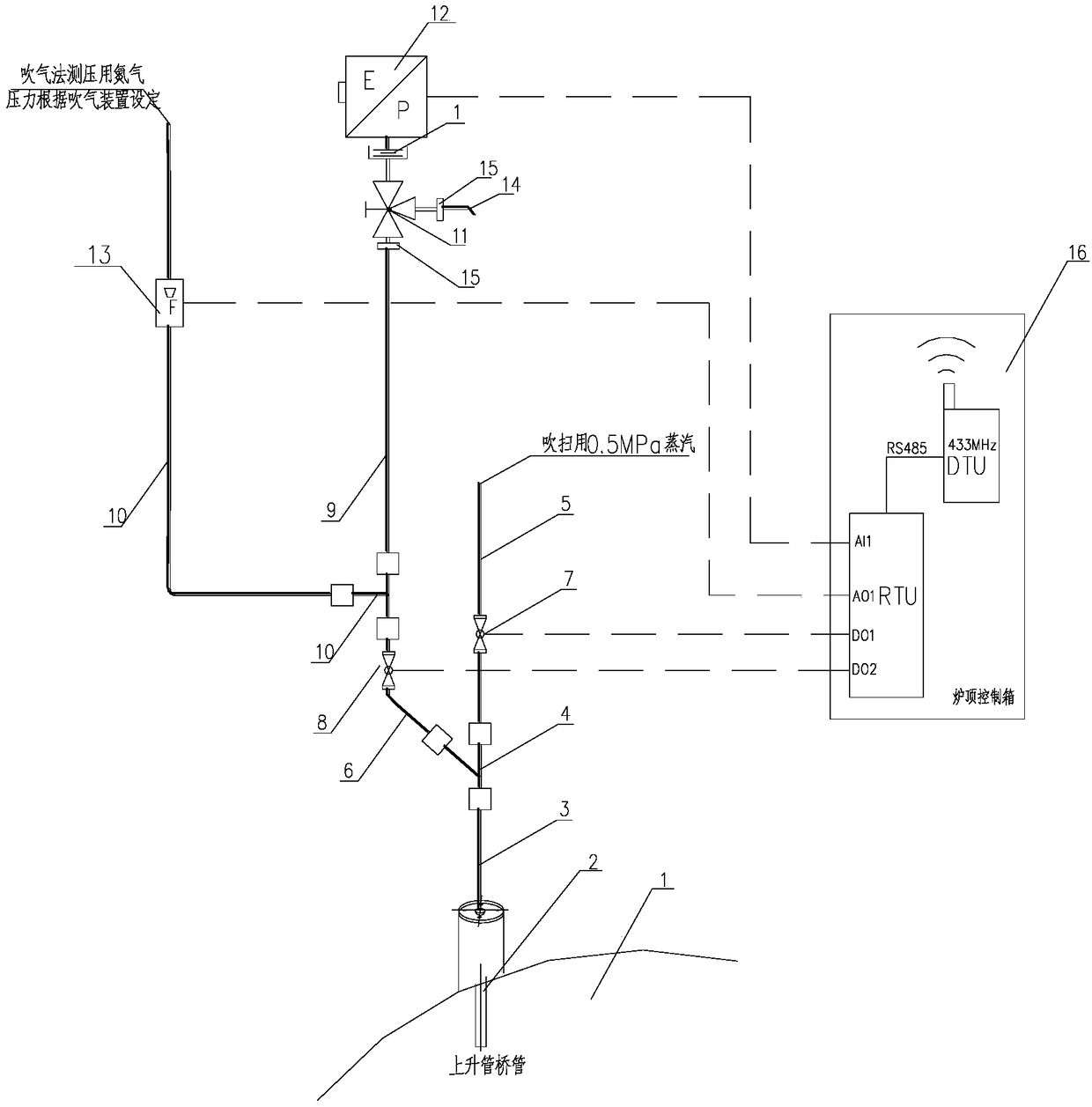

[0025] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] Such as figure 1 As shown, a coke oven bridge pipe raw gas pressure measurement system includes a sampling probe 2, a differential pressure transmitter 12, a constant flow blowing device 13, and also includes a first shut-off valve 7, a second shut-off valve 8, a special-shaped card Set tee joint 4 and tee joint 10.

[0027] The sampling probe 2 is installed at the coke oven riser bridge pipe 1, the outlet of the sampling probe 2 is connected to the special-shaped ferrule tee joint 4 through the sampling main pipeline 3, and the special-shaped ferrule tee joint 4 is divided into two ways: steam blowing Sweep pipeline 5 and pressure detection pipeline 6; the middle of the steam purge pipeline 5 is connected to the steam for purging through the first shut-off valve 7, and the middle of the pressure detection pipeline 6 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com