Pole piece producing and winding defect full-function detection method and system, device and medium

A detection method, a full-featured technology, applied in the direction of optical testing flaws/defects, measuring devices, photo interpretation, etc., can solve the problem of unable to meet the huge demand and high quality requirements of consumers for lithium batteries, and the high precision of cell design. Requirements, can not guarantee the quality of battery winding and other issues, to achieve the effect of solving the problem of glue defects, small errors, and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

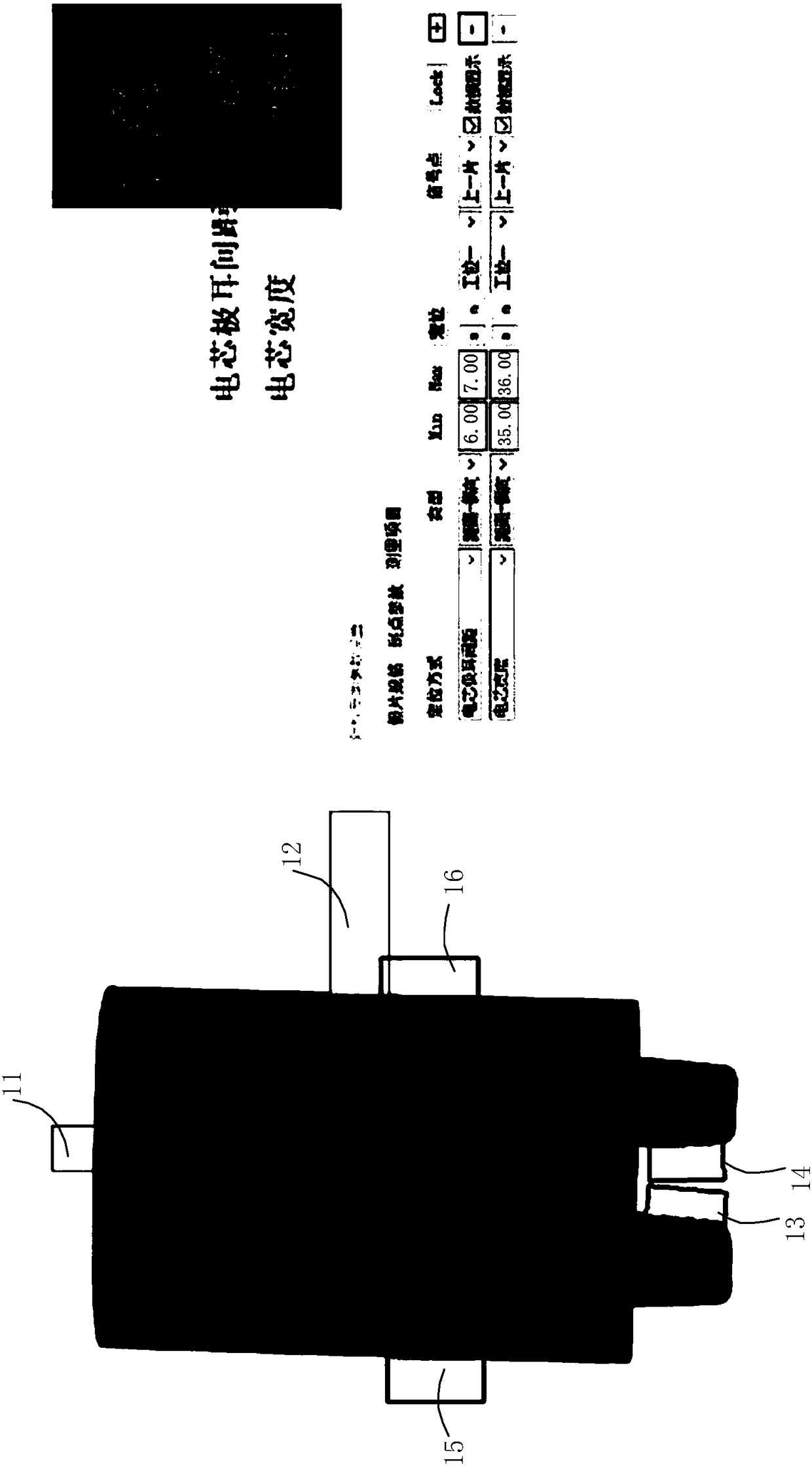

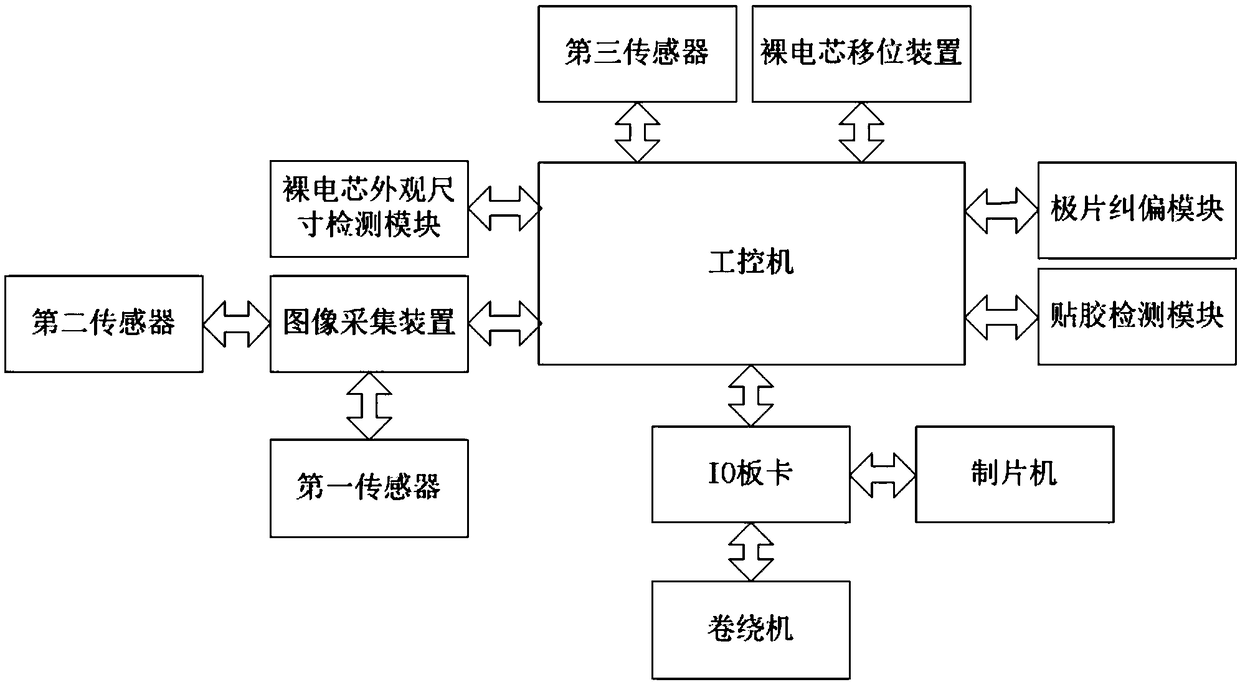

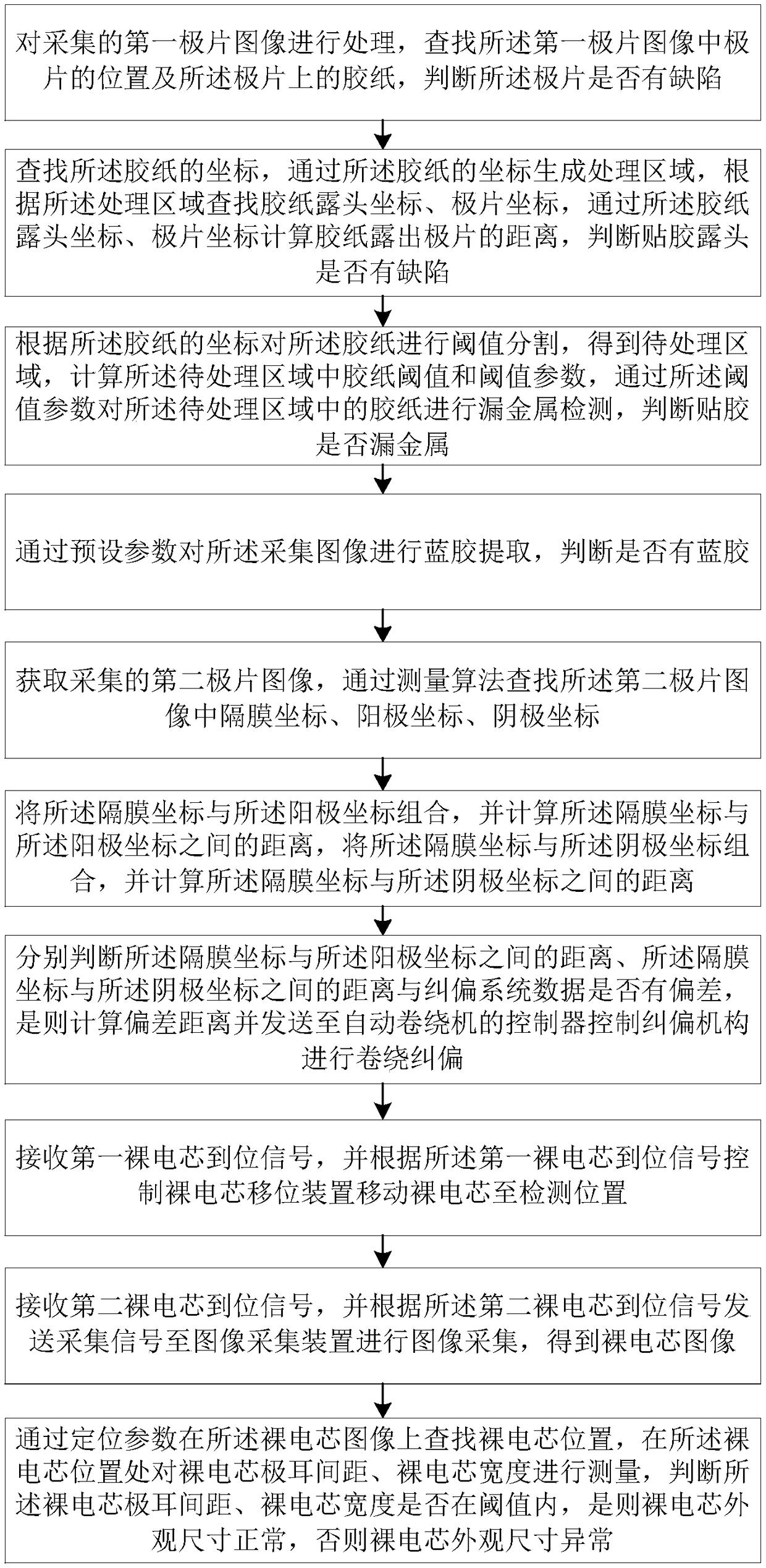

[0045] A full-featured detection system for pole piece winding defects, such as figure 1 As shown, it includes film making machine, winding machine, first sensor, second sensor, third sensor, image acquisition device, IO board, industrial computer, glue detection module, pole piece correction module, appearance and size of bare cell Detection module, bare cell shifting device; the first sensor is connected to the image acquisition device, the image acquisition device is connected to the industrial computer, the industrial computer is connected to the production machine through the IO board, and the glue detection module is installed in the industrial c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com