Flattening and fastening device for 12-inch wafers

A fixing device and flattening technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as affecting subsequent processes, unable to flatten and fix, and achieve the effect of avoiding omission and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following embodiments are combined with the accompanying drawings to explain the composition, working principle, implementation method and beneficial effects of the 12-inch wafer flattening device provided by the present invention. Be specific.

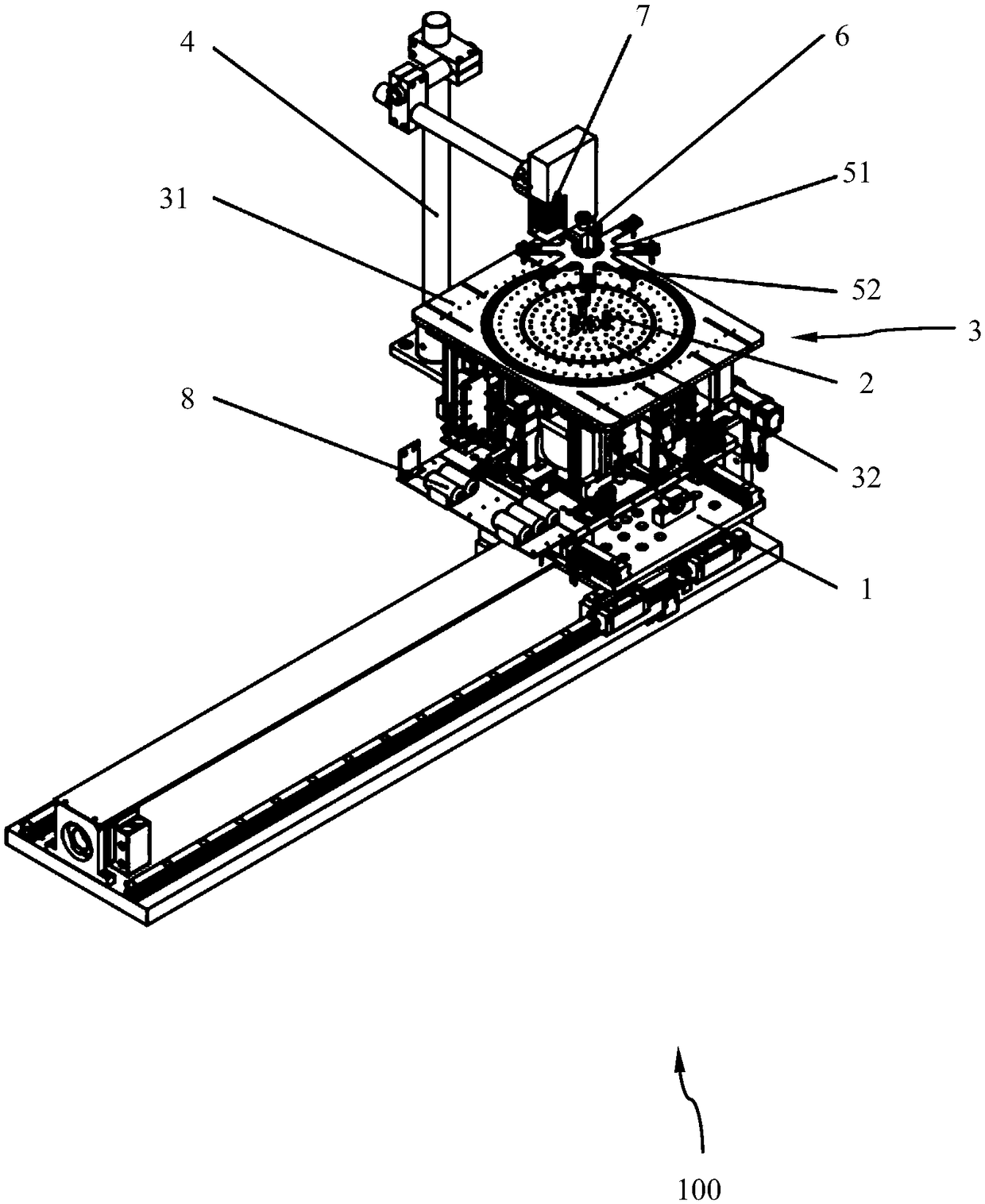

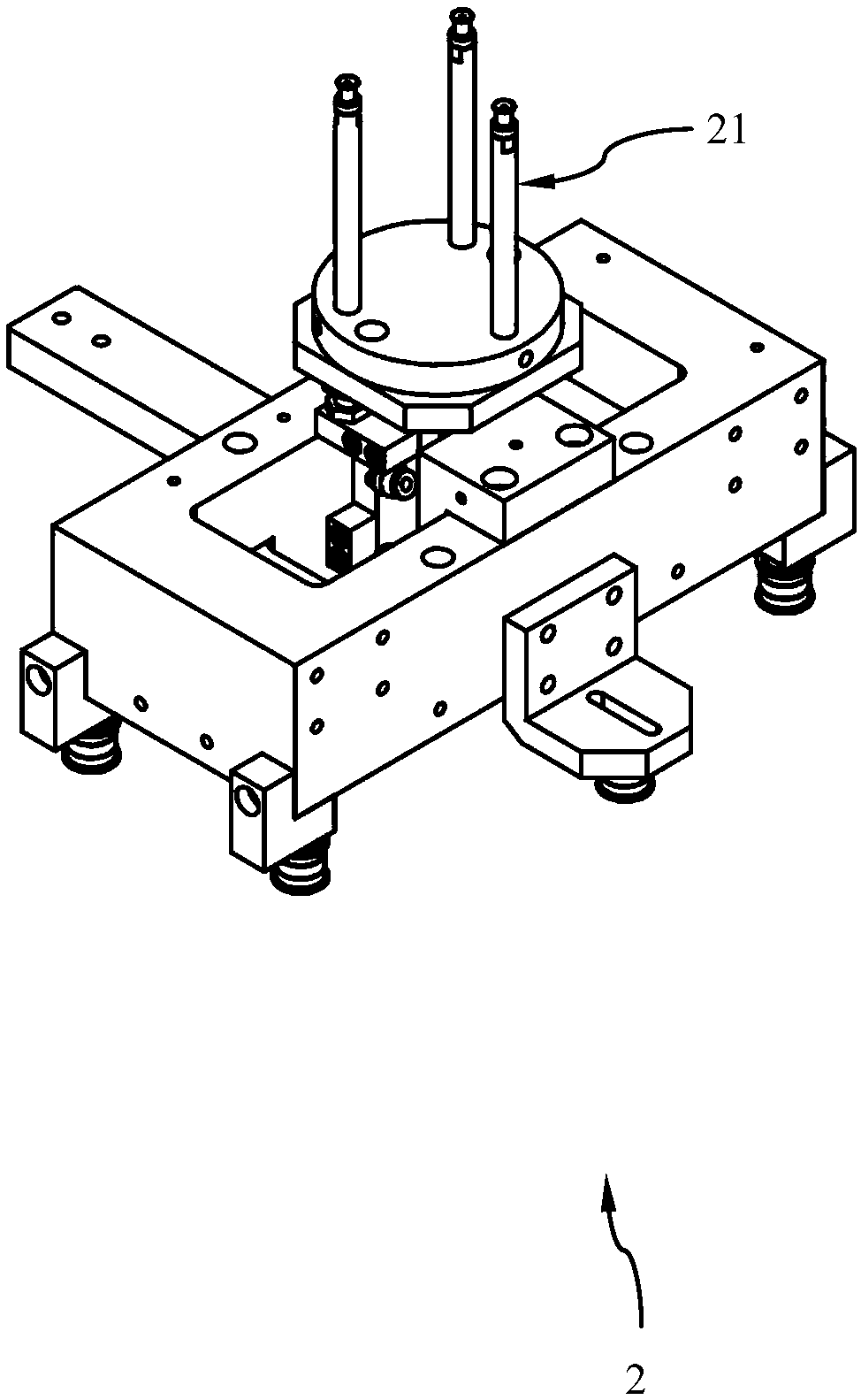

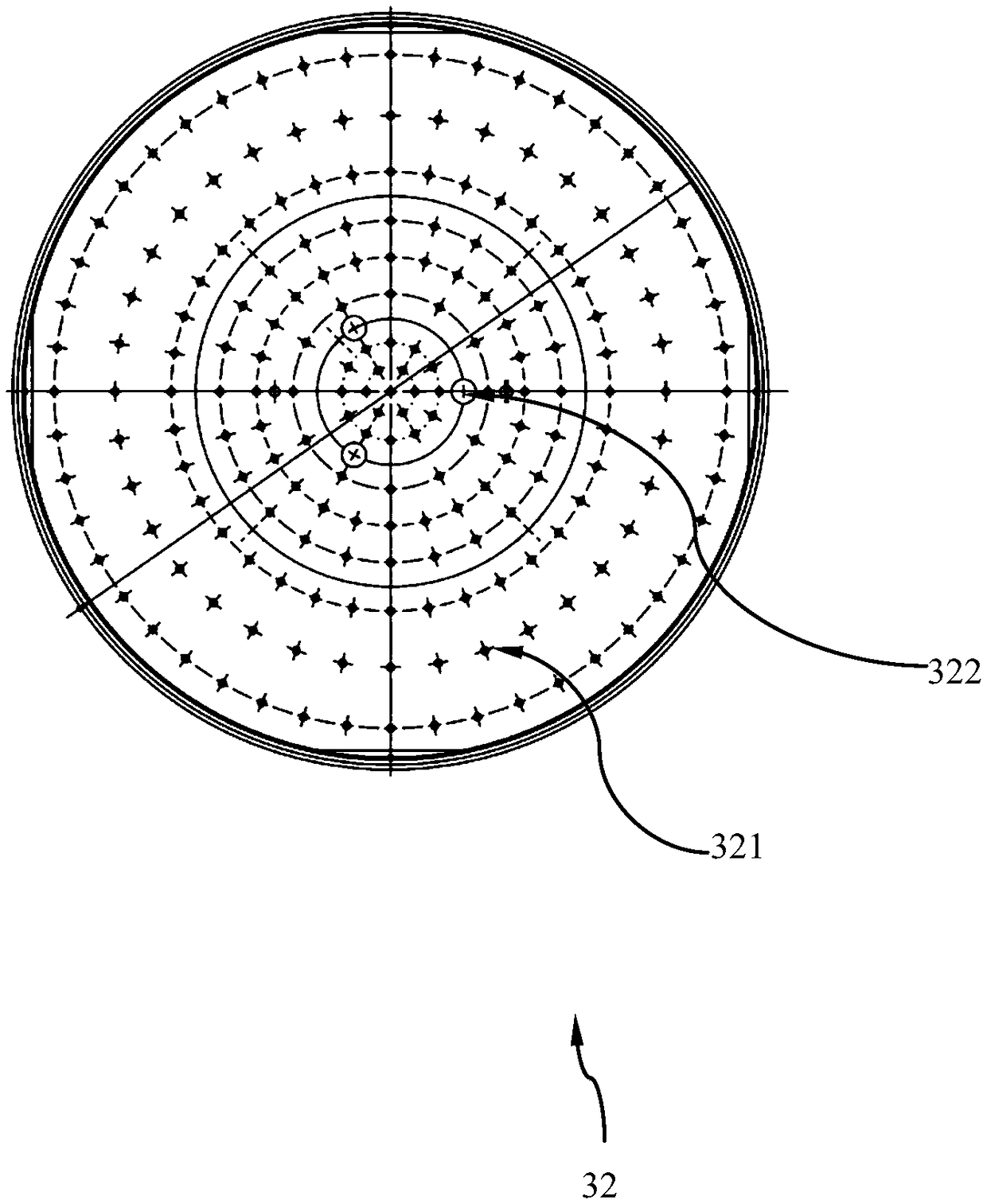

[0026] figure 1 It is a structural schematic diagram of a flattening and fixing device for a 12-inch wafer in an embodiment of the present invention.

[0027] Such as figure 1 As shown, the 12-inch wafer flattening and fixing device 100 in this embodiment is used to flatten and fix warped wafers placed in packaging equipment, and has a carrier table 1, an adsorption fixing part, a crimping fixing part, a detection part and control department.

[0028] The carrying platform 1 is installed in the packaging equipment and can move horizontally between various stations in the packaging equipment.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com