Epitaxial material for N-face light emergence AlGaInP LED thin film chips and preparation method of epitaxial material

A technology of thin-film chips and epitaxial materials, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low electro-optical conversion efficiency, achieve the effects of eliminating light absorption, improving adhesion, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention will be further described.

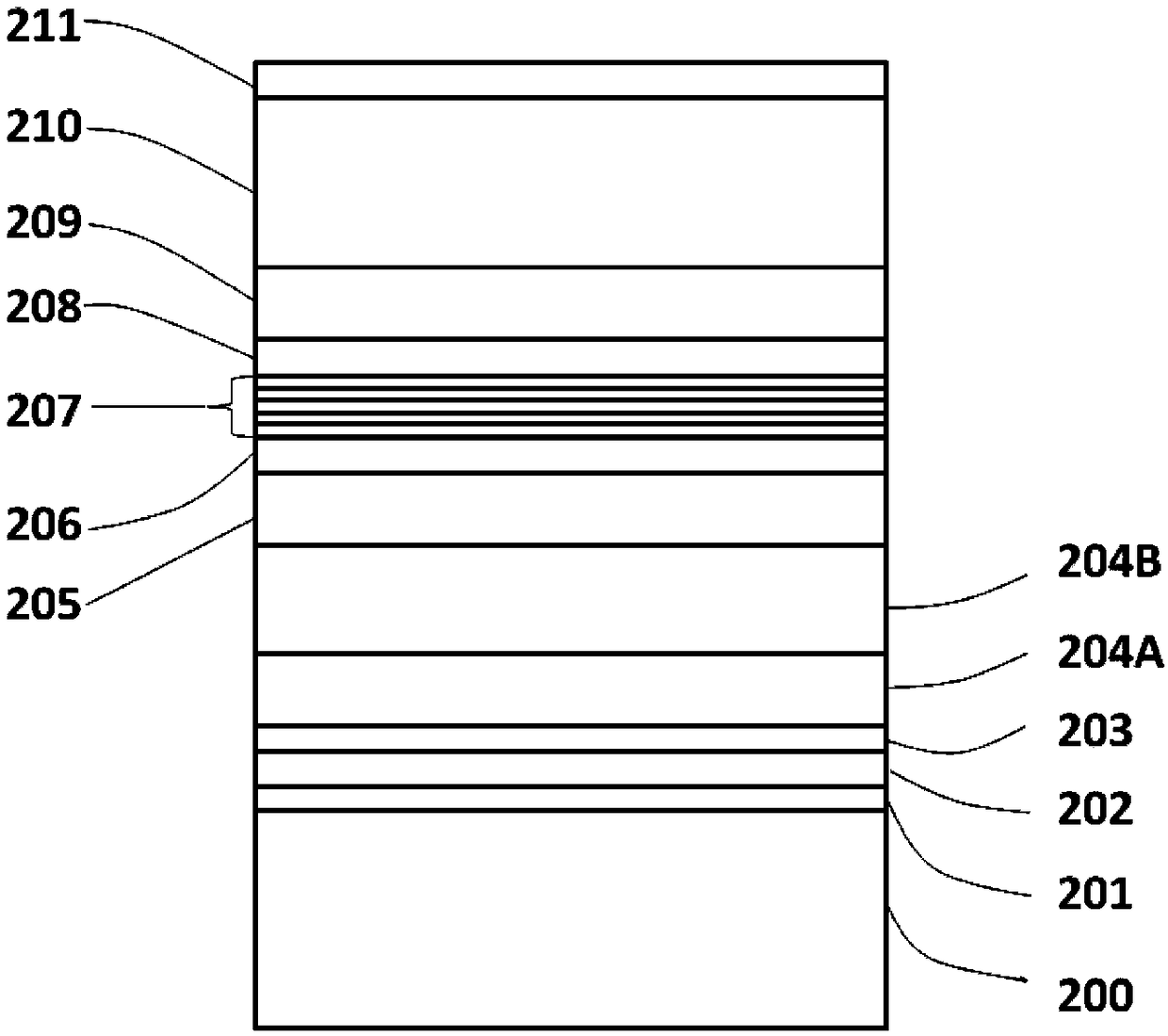

[0027] figure 2It is a schematic structural diagram of an epitaxial material for an N-surface light-emitting AlGaInP LED thin film chip of the present invention. According to the sequence of epitaxial growth, it includes an N-type GaAs substrate 200, an N-type GaAs buffer layer 201, and a first etch layer from bottom to top. Barrier layer 202, second corrosion barrier layer 203, first N-type roughened layer 204A, second N-type roughened layer 204B, N-type confinement layer 205, N-side space layer 206, multiple quantum well light-emitting region 207, P-side The space layer 208 , the P-type confinement layer 209 , the P-type current spreading layer 210 and the P-type ohmic contact layer 211 .

[0028] The (Al x1 Ga 1-x1 ) y1 In 1-y1 1P material with a forbidden band width than that used in the quantum wells of the multi-quantum well light-emitting region 207 (Al x5 Ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com