Electronic cigarette, sheet heating body of electronic cigarette and preparation method of sheet heating body

A technology of heating elements and electronic cigarettes, applied in the field of electronic cigarettes, can solve the problems of unfavorable risks for consumers, insertion of heating elements into shredded tobacco, and harmful substances in shredded tobacco, so as to improve heating stability, uniformity of baking temperature, and stable performance and quality Performance and service life, temperature measurement accuracy comprehensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

[0035] The invention adopts the heating principle of ceramic internal resistance wire and new ceramic technology to prepare a heating element with excellent performance and quality, which can improve the series of defects existing in the center heating of the existing resistance wire heating element.

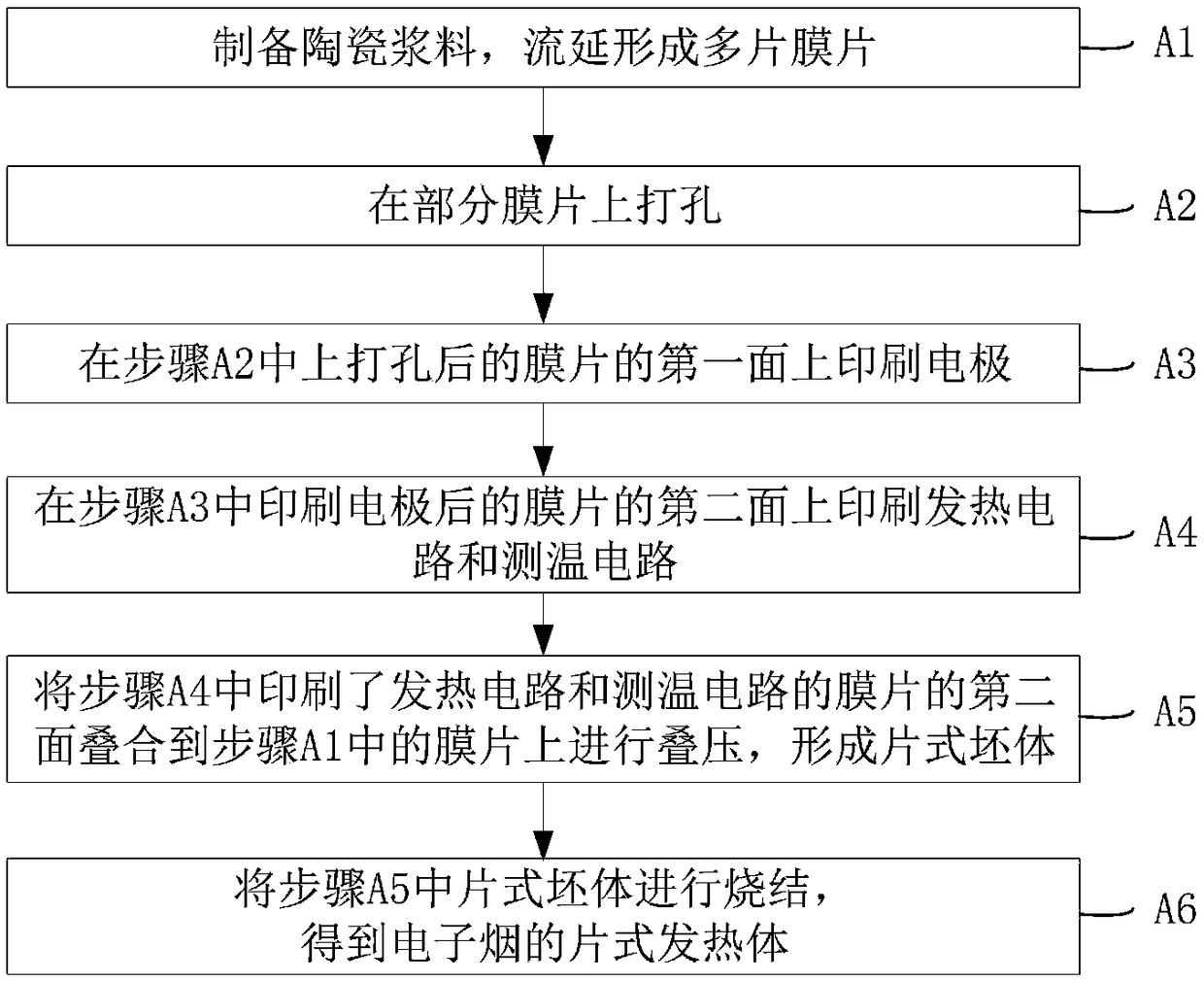

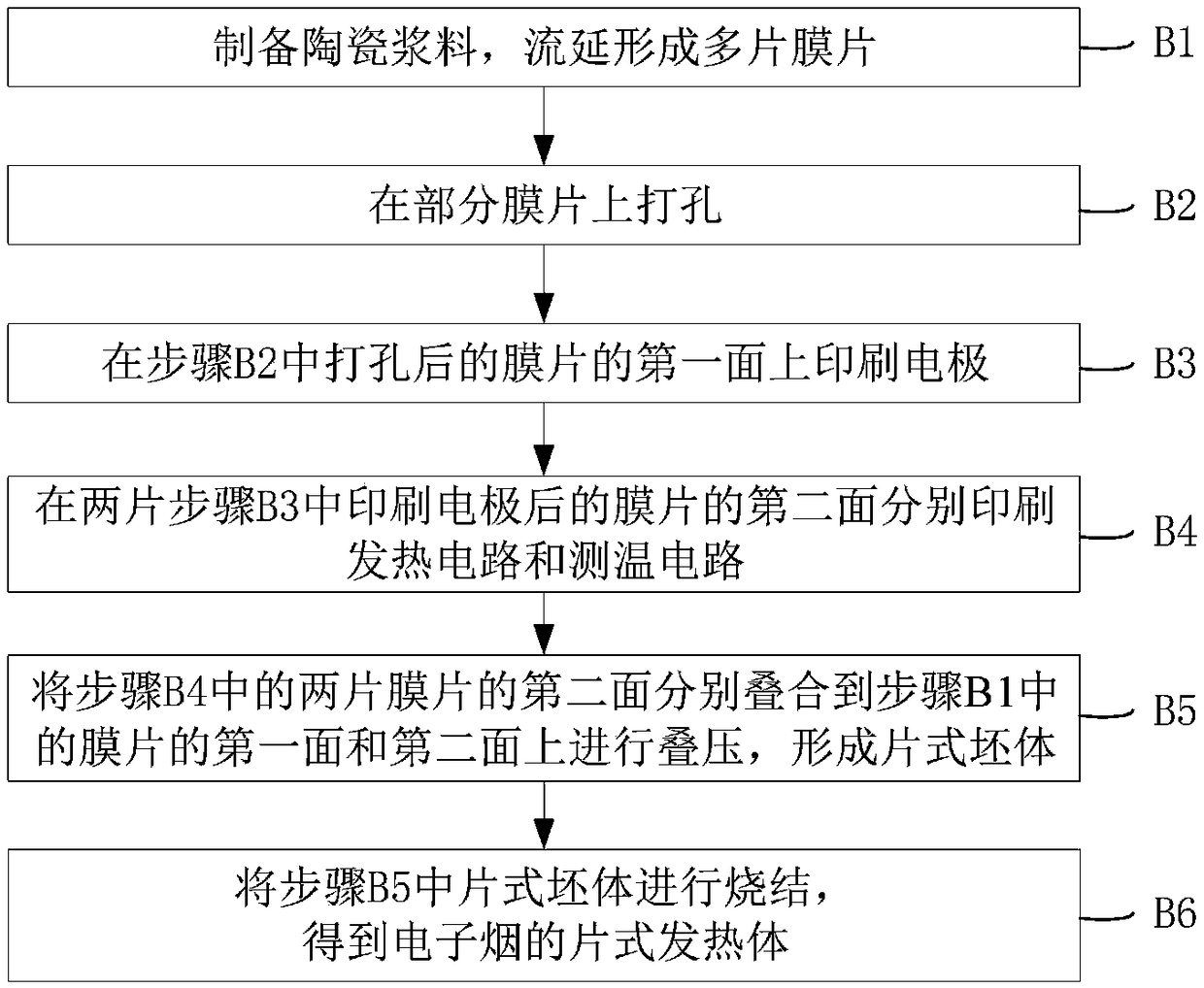

[0036] Such as figure 1 As shown, Embodiment 1 of the present invention discloses a method for preparing a sheet-type heating element of an electronic cigarette, including the following steps:

[0037] A1: Prepare ceramic slurry and cast to form multiple diaphragms;

[0038] Specifically, the ceramic slurry includes alumina (Al 2 o 3 ), zirconia (ZrO), aluminum nitride (AlN), silicon carbide (SiC), silicon nitride (Si 3 N 4 ) of at least one, by casting the ceramic slurry to make the film thickness reach the design value, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com