Anticorrosive reaction kettle convenient for pressure detection

A reaction kettle and corrosion-resistant technology, applied in the field of pressure detection, can solve the problems of easily damaged pressure detection device and high temperature, and achieve the effects of saving land, low temperature and high reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

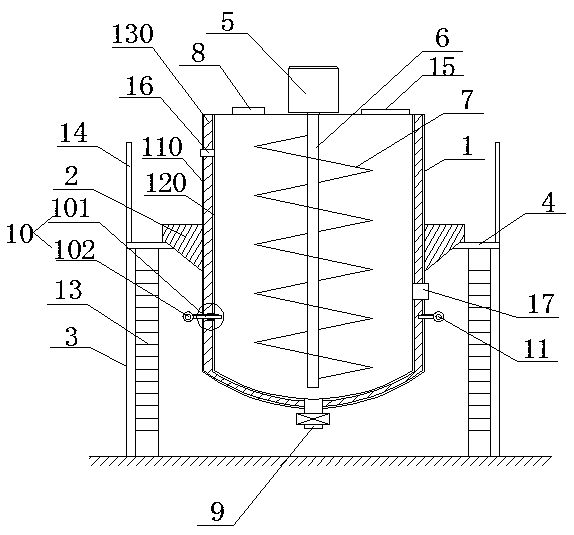

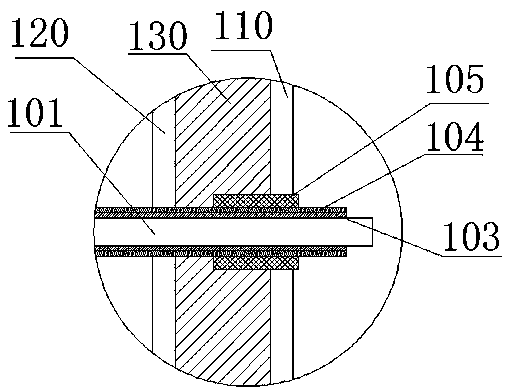

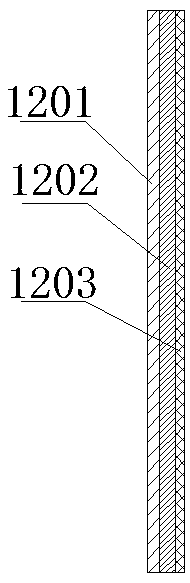

[0022] Such as figure 1 , figure 2 , image 3 A corrosion-resistant reactor convenient for pressure detection is shown, including a reactor body 1, a connecting bracket 2, a supporting frame 3, and a secondary platform 4. The reactor is provided with a connecting bracket, and the connecting bracket is connected to the secondary platform. The two-level platform is connected to the supporting frame. The reaction kettle of the present invention has two layers, the upper and the lower. During actual operation, workers operate on the two-level platform to realize feeding. The top of the reactor body is provided with a motor 5, the motor is connected to the stirring shaft 6, the stirring shaft is located in the reactor body, the stirring shaft is connected to the stirring paddle 7, the top of the reactor body is also provided with a material inlet 8, and the bottom of the reactor body is provided with Material export9. The material enters from the material inlet, and then reacts...

Embodiment 2

[0030] Such as Figure 4 As shown, in the present invention, the pressure detection body includes an amplifier, an A / D converter, a single-chip microcomputer, an LED display, and of course a casing. The pressure signal of the position to be detected is converted into an electrical signal through the pressure sensing probe, and then the signal is amplified by the operational amplifier, and sent to the 8-bit A / D converter, and then the analog signal is converted into a digital signal that can be recognized by the single-chip microcomputer, and then passed through The single-chip microcomputer converts the display information that can be recognized by the LED display, and finally outputs and displays it on the instrument panel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com