High-speed geotechnical centrifugal machine structure

A geotechnical centrifuge, high-speed technology, applied in the field of centrifuges, can solve problems such as the influence of the running stability of the centrifuge, and achieve the effect of improving the anti-overturning ability, avoiding resonance, and satisfying the conditions of stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

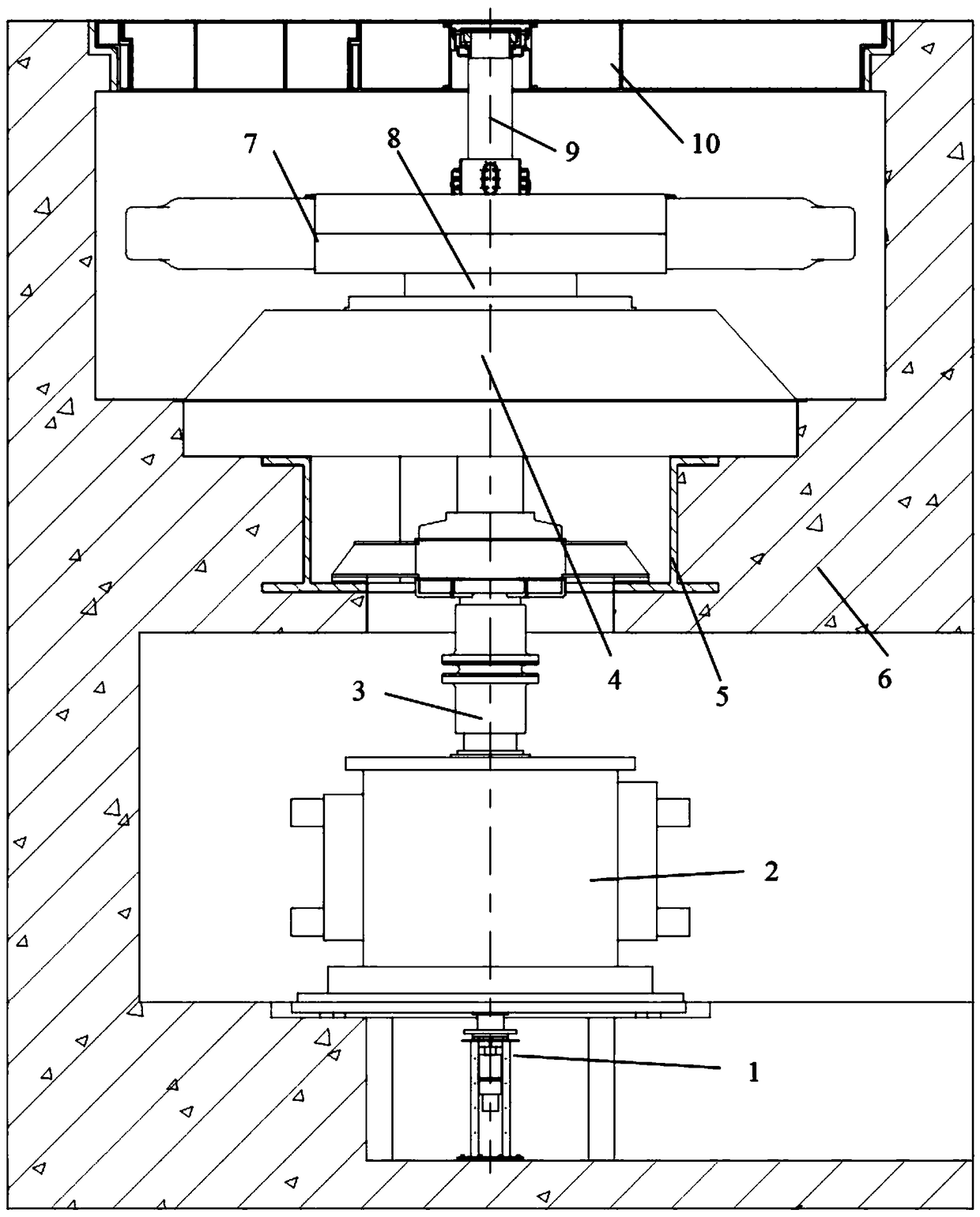

[0047] Example 1, such as figure 1 as shown,

[0048] A high-speed geotechnical centrifuge structure, installed in the concrete machine room 6, the concrete machine room 6 includes an underground negative floor and an underground negative second floor connected up and down, and the high-speed geotechnical centrifuge structure includes:

[0049] The main shaft 9 of the hollow structure;

[0050] The coupling 3, the motor 2, and the collector ring 1 for controlling the speed of the motor 2 are installed in the negative second floor of the concrete machine room 6; the motor 2 is installed in the concrete machine room 6 of the negative second floor underground, and the motor 2 The rotating shaft is connected to the main shaft 9 through the coupling 3; the collector ring 1 is installed at the lower part of the motor 2, and the water, electricity and air are transported into the main shaft 9 through the collector ring 1;

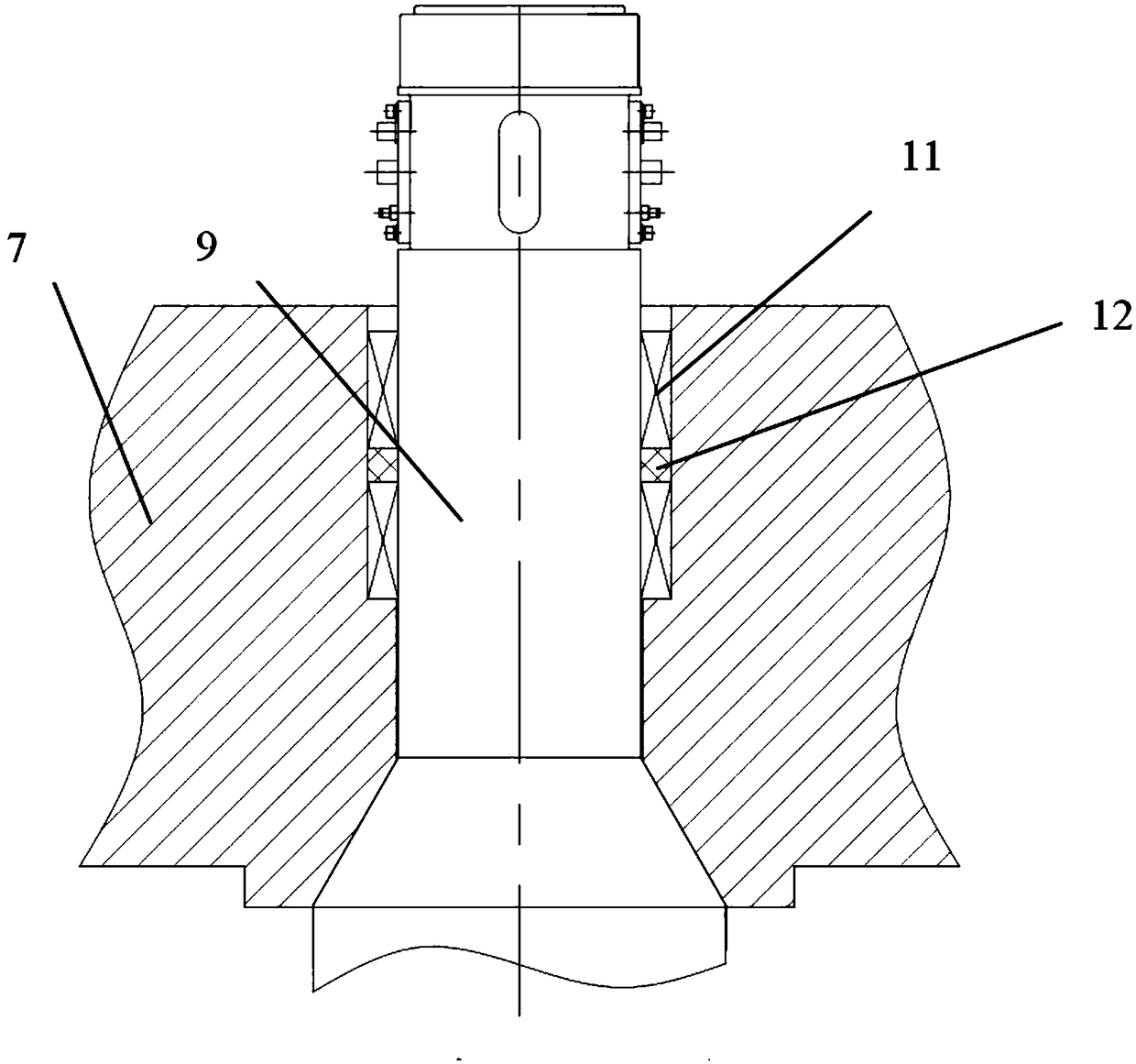

[0051] The rotating arm 7 and the middle transmission supp...

Embodiment 2

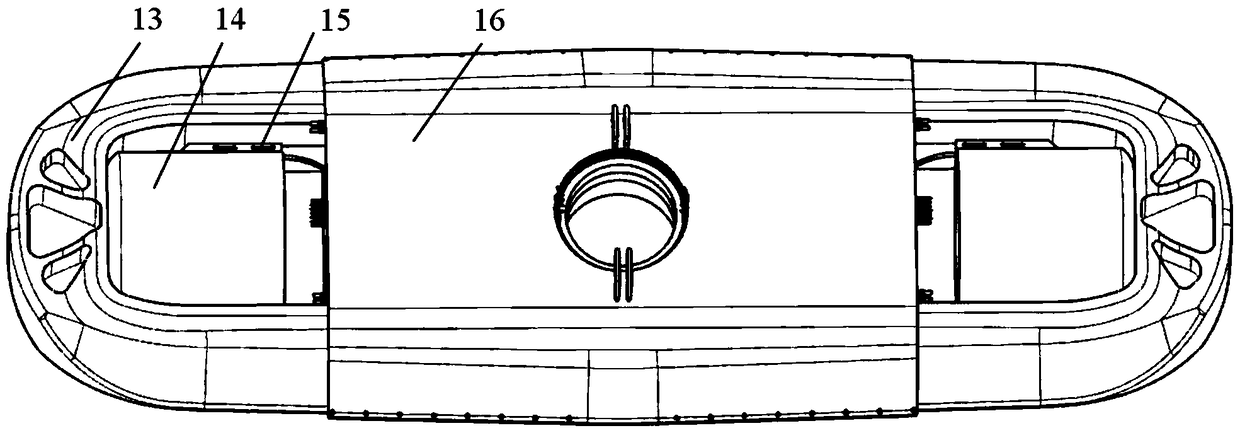

[0056] Example 2, such as image 3 as shown,

[0057] The difference between this embodiment and Embodiment 1 is that the rotating arm 7 includes:

[0058] Arm frame 13; the arm frame 13 is an integrally forged pocket beam structure;

[0059] pipeline support 16; the pipeline support 16 is set in the middle of the boom 13;

[0060] Slide rails 15; a group of slide rails 15 are arranged at both ends of the boom 13, and the installation direction of the slide rails 15 is perpendicular to the main shaft 9;

[0061] Hanging basket 14; the hanging basket 14 is slidably installed in the slide rail 15. When the high-speed geotechnical centrifuge rotates, the hanging basket 14 and the model in it will slide along the slide rail 15 under the action of centrifugal force, so that the bottom of the hanging basket 14 In contact with the boom 13.

[0062] The arm frame 13 adopts a pocket beam structure, which is integrally forged during manufacture, and can withstand a centrifugal force...

Embodiment 3

[0063] Example 3, such as Figure 4 as shown,

[0064] The difference between this embodiment and Embodiment 1 is that the structure of the high-speed geotechnical centrifuge also includes:

[0065] The upper transmission support, the upper transmission support includes an upper guide bearing seat 17 and an upper guide radial bearing 18; the upper guide bearing seat 17 is installed in the machine room cover plate 10, and the upper guide radial bearing 18 is set on the upper part of the main shaft 9 and installed on the On the upper guide bearing seat 17;

[0066] The lower transmission support; the lower transmission support includes the lower guide bearing seat 22 and the lower guide radial bearing 23, the lower guide bearing seat 22 is installed on the embedded part 5, the lower guide radial bearing 23 is set on the lower part of the main shaft 9, and is installed on the lower guide On the bearing seat 22;

[0067] The middle transmission support 4 includes a middle guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com