Bolt installing device

An installation device and bolt technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of reduced operation speed, bolt assembly errors, cumbersome installation process, etc., to reduce the probability of assembly errors, and not easy to malfunction. , the effect of reducing the amount of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described with reference to the accompanying drawings.

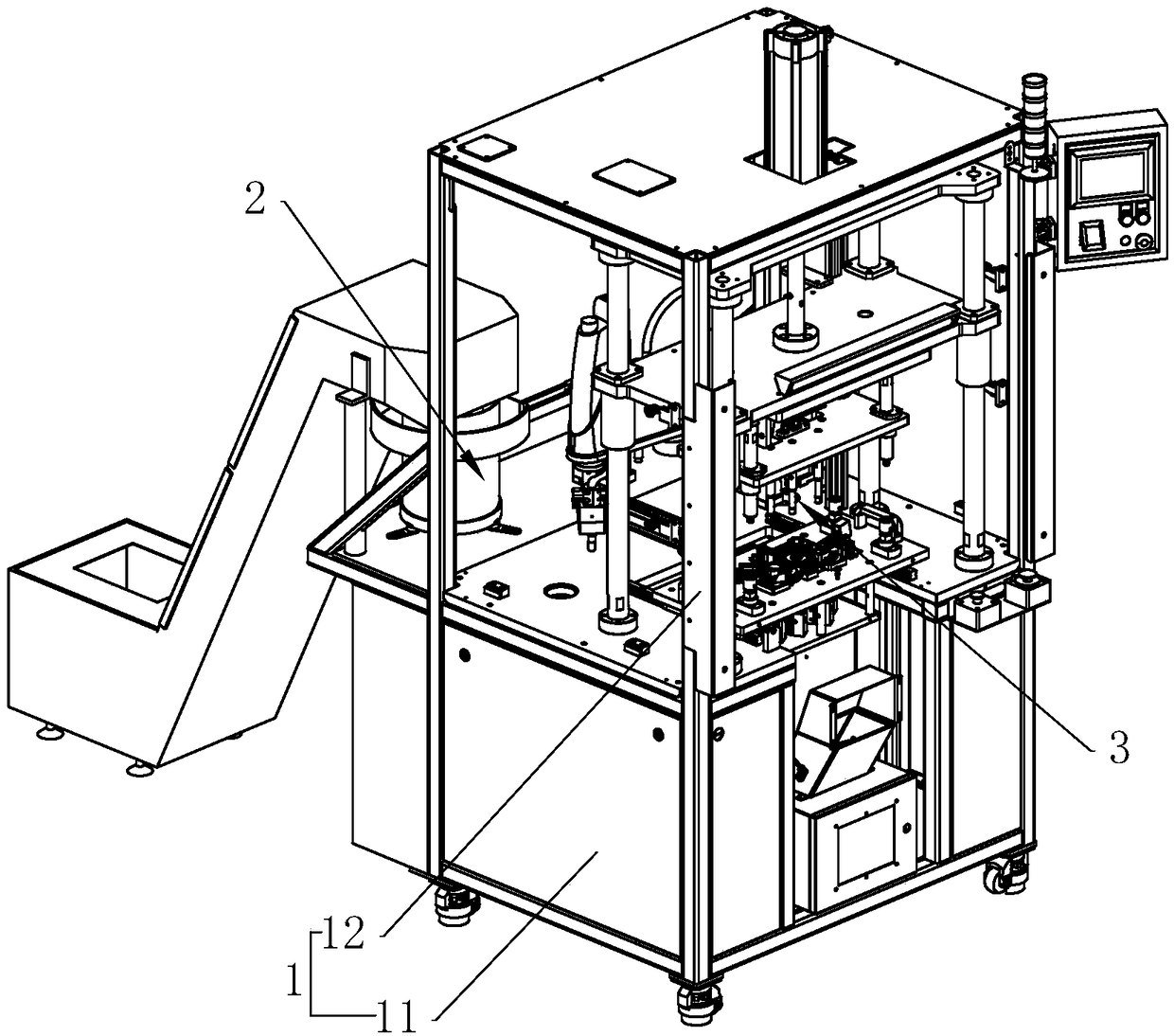

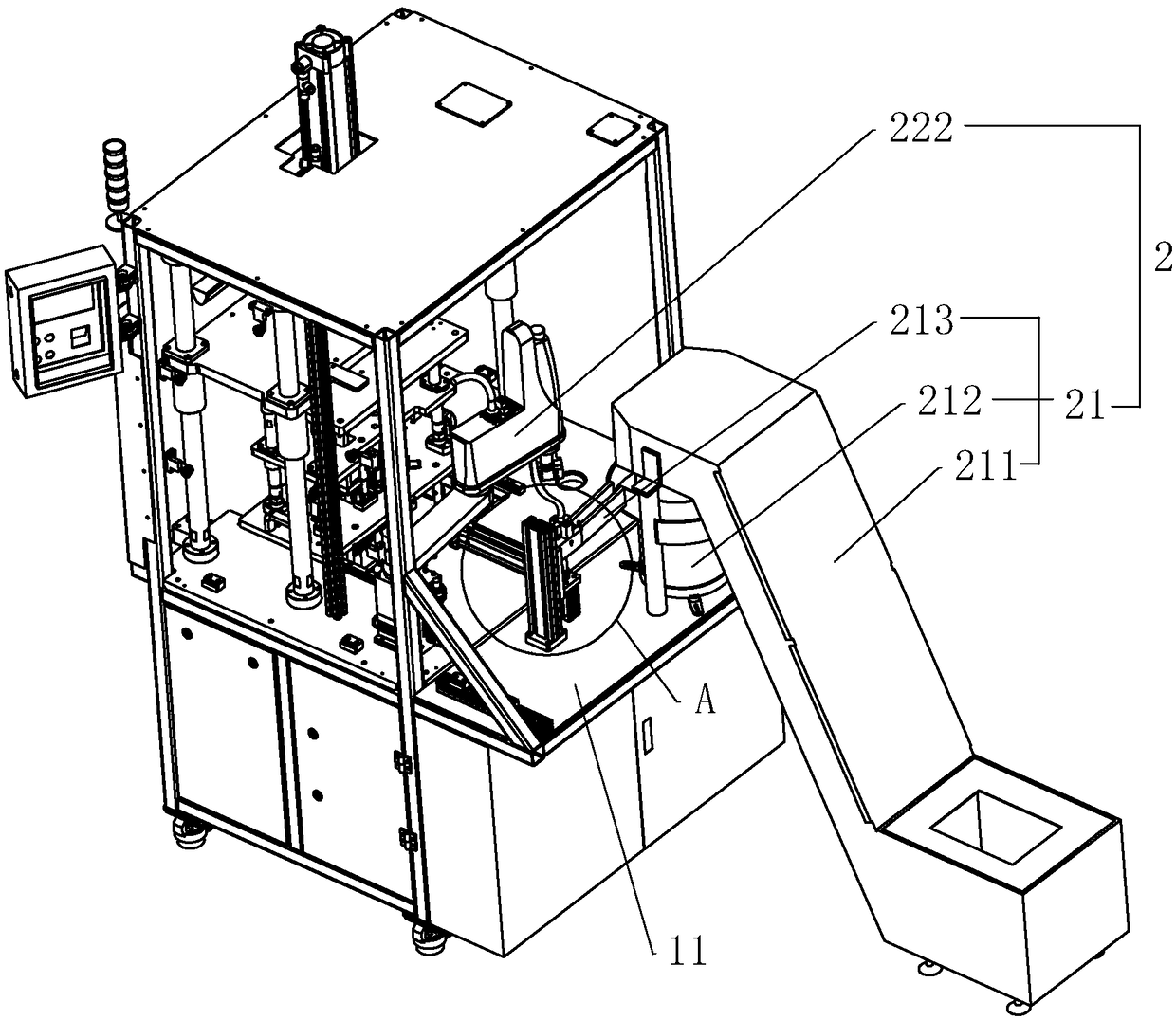

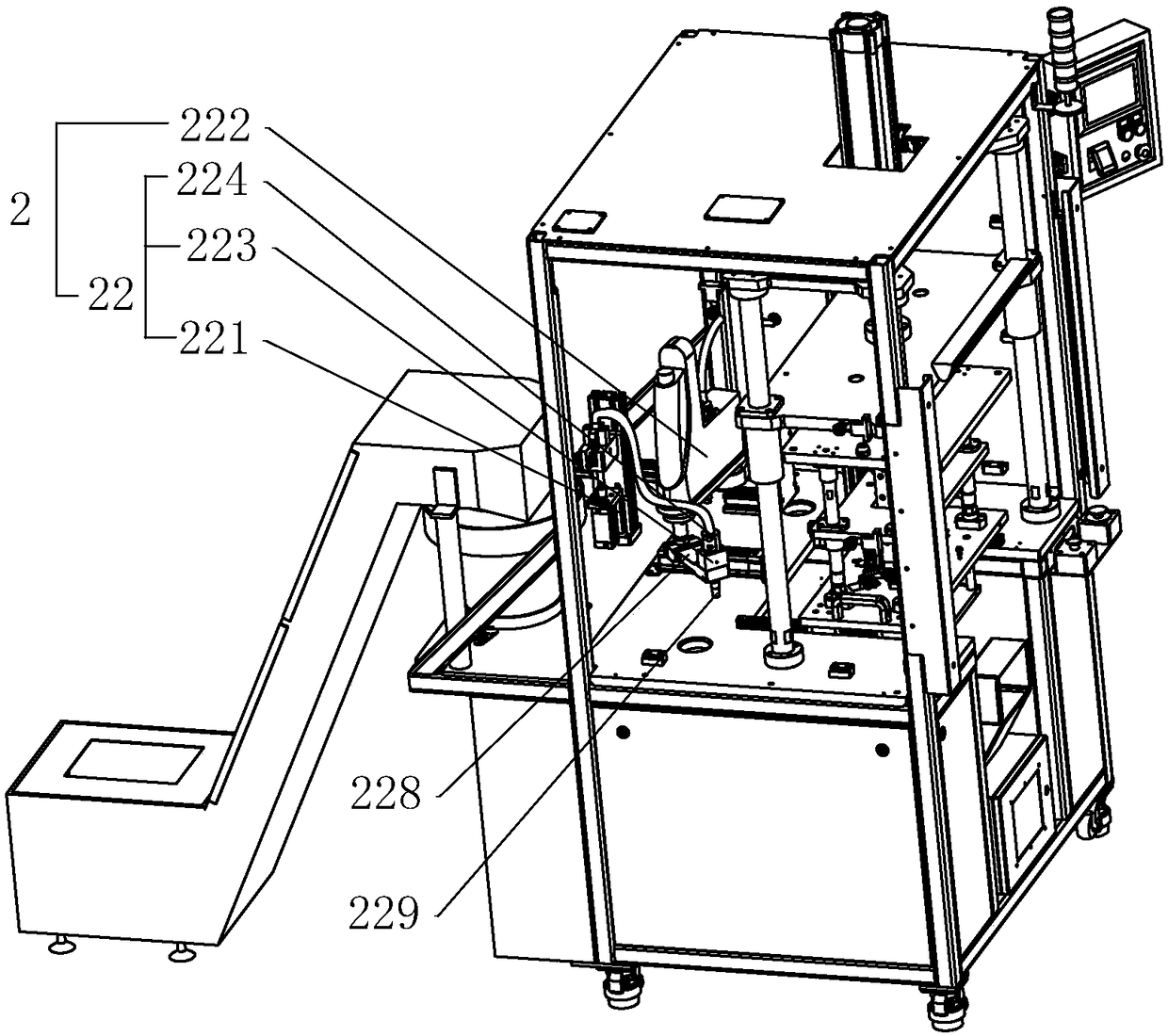

[0035]As shown in the figure and the figure, a bolt installation device includes a frame 1, on which a placement device 2 and a bolt installation assembly 3 are arranged, the frame 1 includes a base 11 and a mounting frame 12, and the mounting frame 12 is fixedly connected on the base 11. The placing device 2 includes a feeding assembly 21, a manipulator 222 and a conveying assembly 22. The feeding assembly 21 includes a hoist 211, a vibrating plate 212 and a feeding frame 213. The hoisting machine 211 is fixedly connected to the base 11, and the vibrating plate 212 is fixedly connected to the base 11. On the base 11 , a material delivery frame 213 with a C-shaped cross section is fixedly connected to the discharge port of the vibrating plate 212 , and the discharge port of the hoist 211 is located directly above the vibrating plate 212 . As shown in the figure and the figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com