Vehicle backstop sliding window assembly

A technology for sliding windows and components, which is applied to vehicle components, windows, windshields, etc., and can solve the problems of cable bending damage, easy bending damage of cables, increased structural complexity and production costs of rear window sliding windows, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

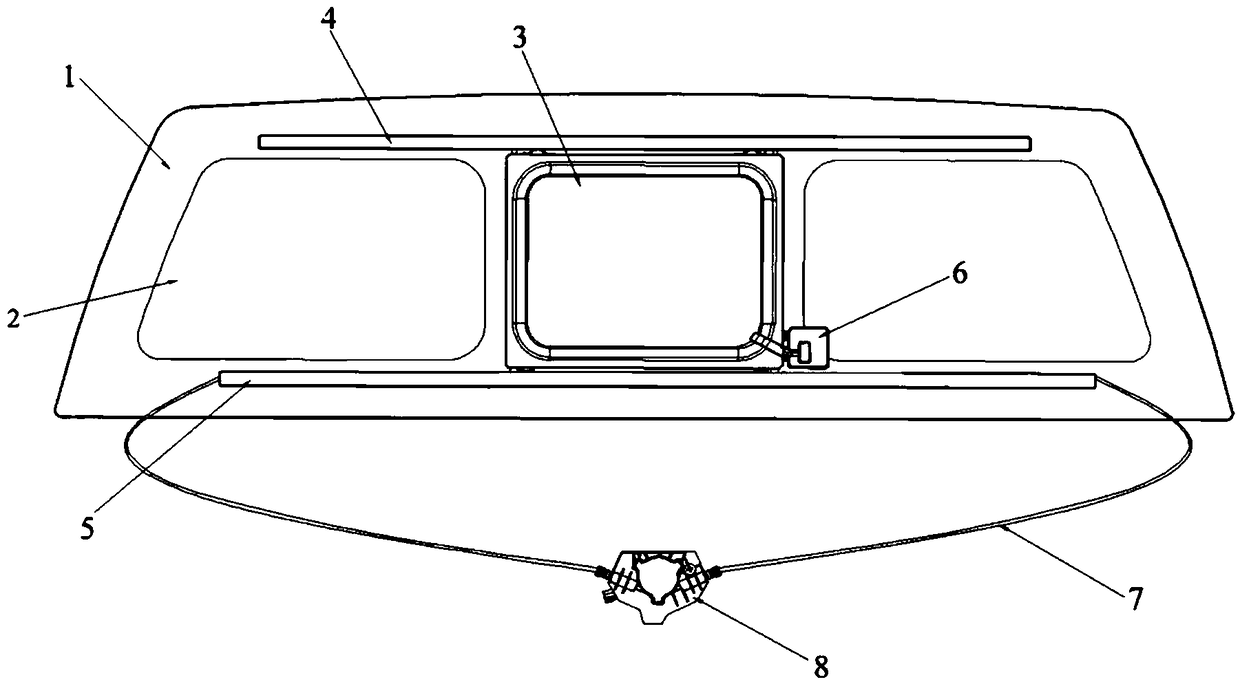

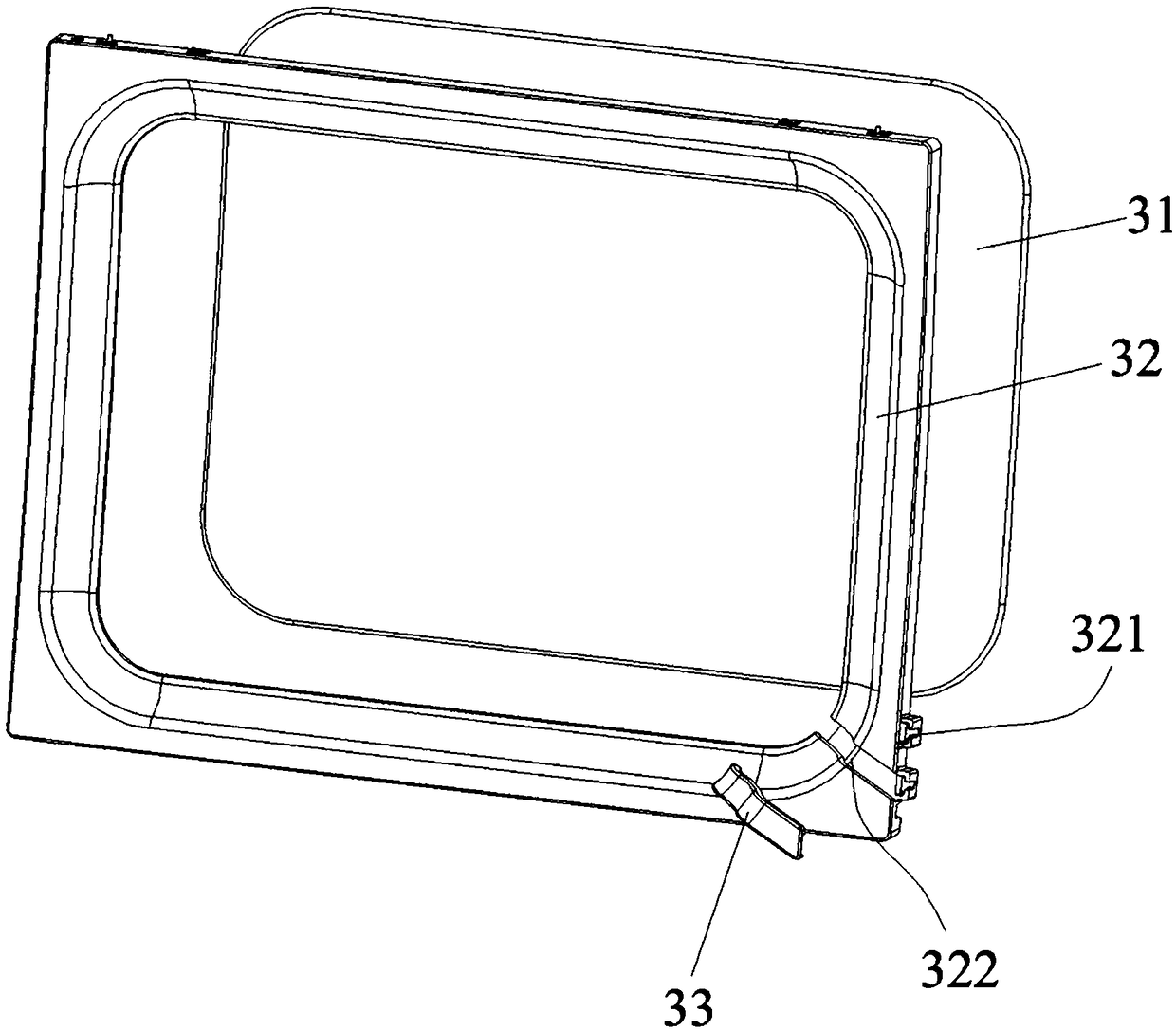

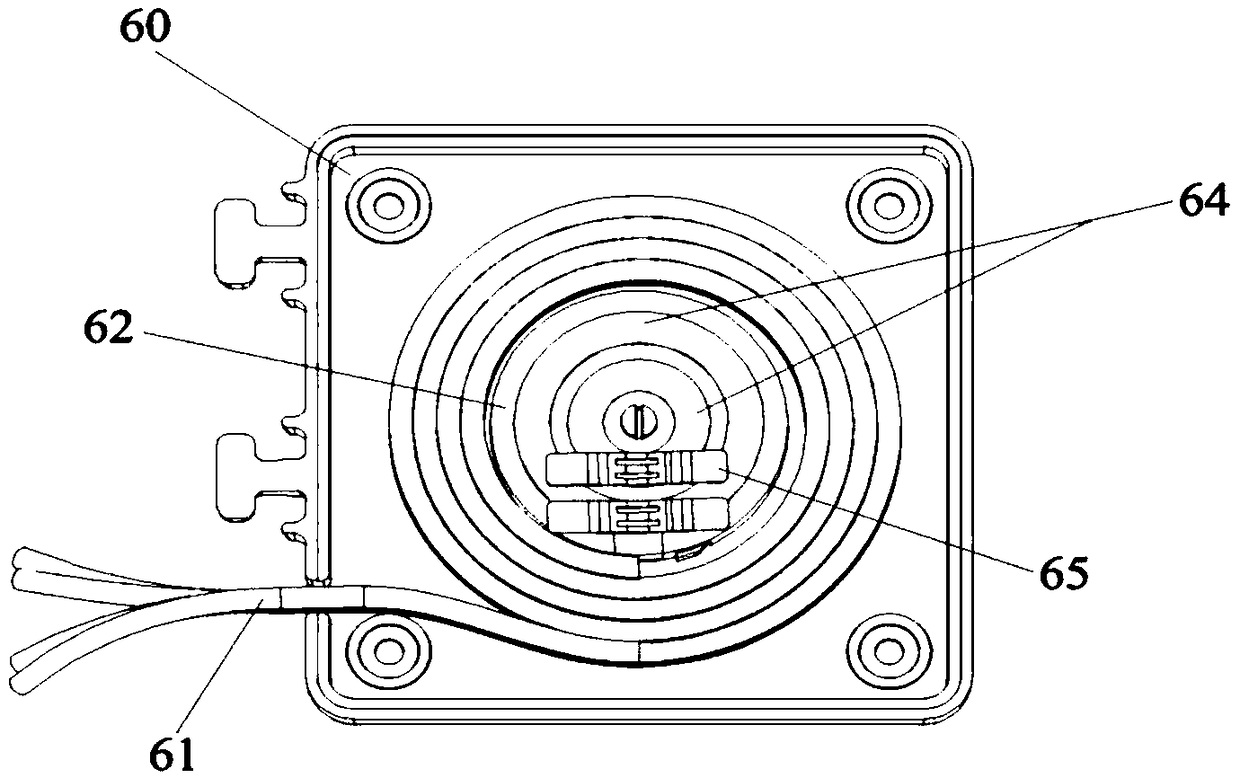

[0053] Such as figure 1 and Figure 11 As shown, the upper guide rail 4 is provided with a first slide rail 41, the lower guide rail 5 is provided with a second slide rail 51, and the upper edge of the sliding window frame 32 is provided with a first guide column 323 that slides with the first slide rail 41. , the lower portion of the sliding window frame 32 is provided with a second guide post 324 that is slidingly connected to the second slide rail 51, the first slide rail 41 and the second slide rail 42 are linear slide rails, and one end of the cable 7 on the lower guide rail 5 is connected to the second guide rail 51. The motor 8 is connected, and the other end is connected with the second guide post 324, and the limit block 52 is installed on the cable 7. The sliding window 3 is pulled by cables to slide on the first slide rail 41 and the second slide rail 42. Since the first slide rail 41 and the second slide rail 42 are both linear slide rails, during the opening and ...

Embodiment 2

[0055] The difference between this embodiment and Embodiment 1 lies in the structures of the first slide rail 41 and the second slide rail 42 , and the other structures are the same. Such as figure 1 , Figure 11 , Figure 12 and Figure 13 As shown, the first slide rail 41 is composed of a first straight section 411 and a first hook-shaped curved section 412 , and the second slide rail 51 is composed of a second straight section 511 and a second hook-shaped curved section 512 . The sliding window 3 slides on the first slide rail 41 and the second slide rail 42 by the traction of cables. When the sliding window 3 was fully closed, the first guide post 323 and the second guide post 324 on the sliding window frame 32 were respectively positioned at the first At the top of the hook-shaped curved section 412 and the second hook-shaped curved section 512, the sliding glass 31 on the sliding window 3 and the fixed glass 2 are flush structures on the same plane; when the sliding w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com