Integrated electric heating ceramic tile

A ceramic tile and electric heating technology, which is applied in the field of ceramic tiles, can solve problems such as ceramic tile sinking under heavy pressure, carbon crystal leakage, and electric heating plate power increase, etc., to achieve the effect of convenient splicing and installation, and increasing indoor temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

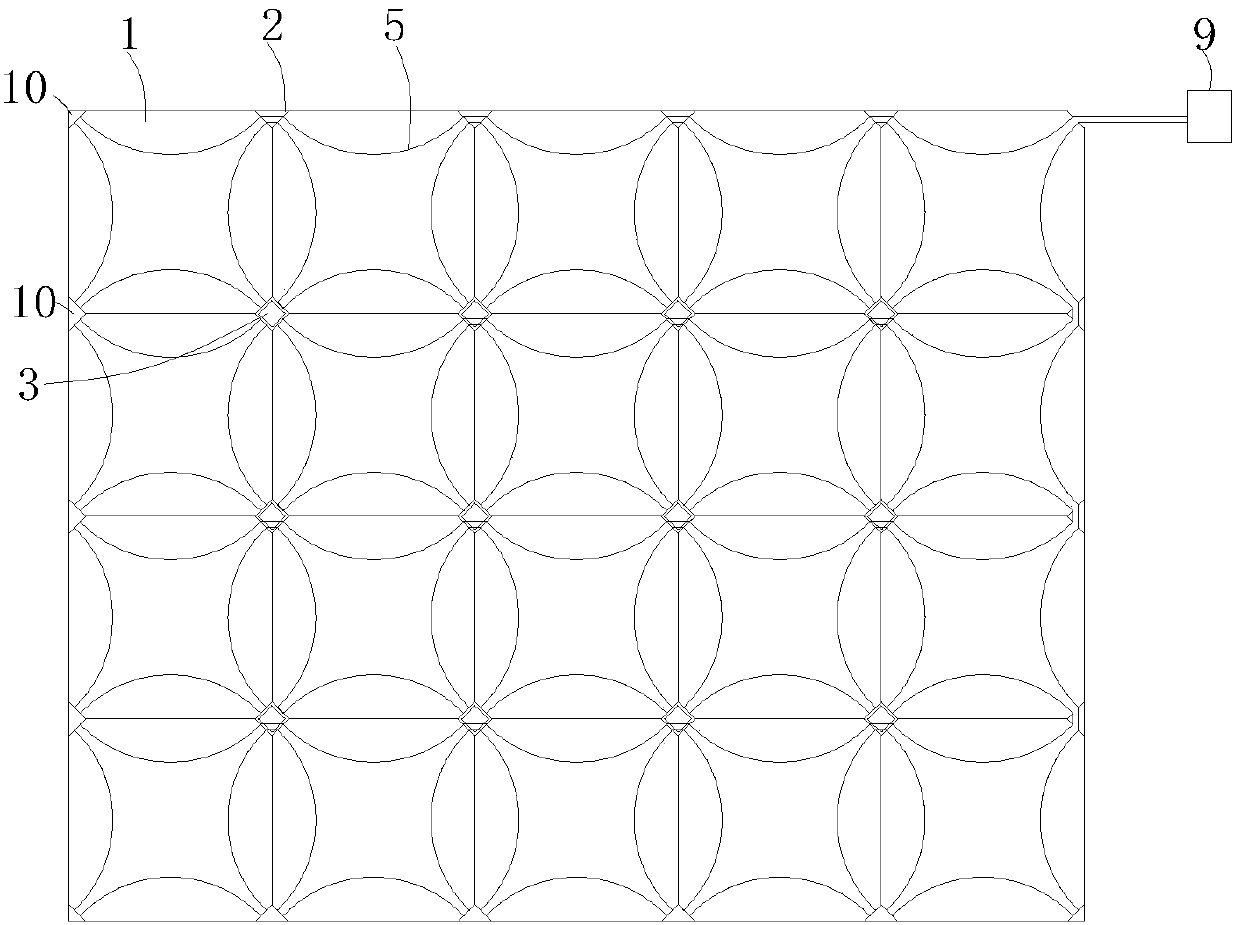

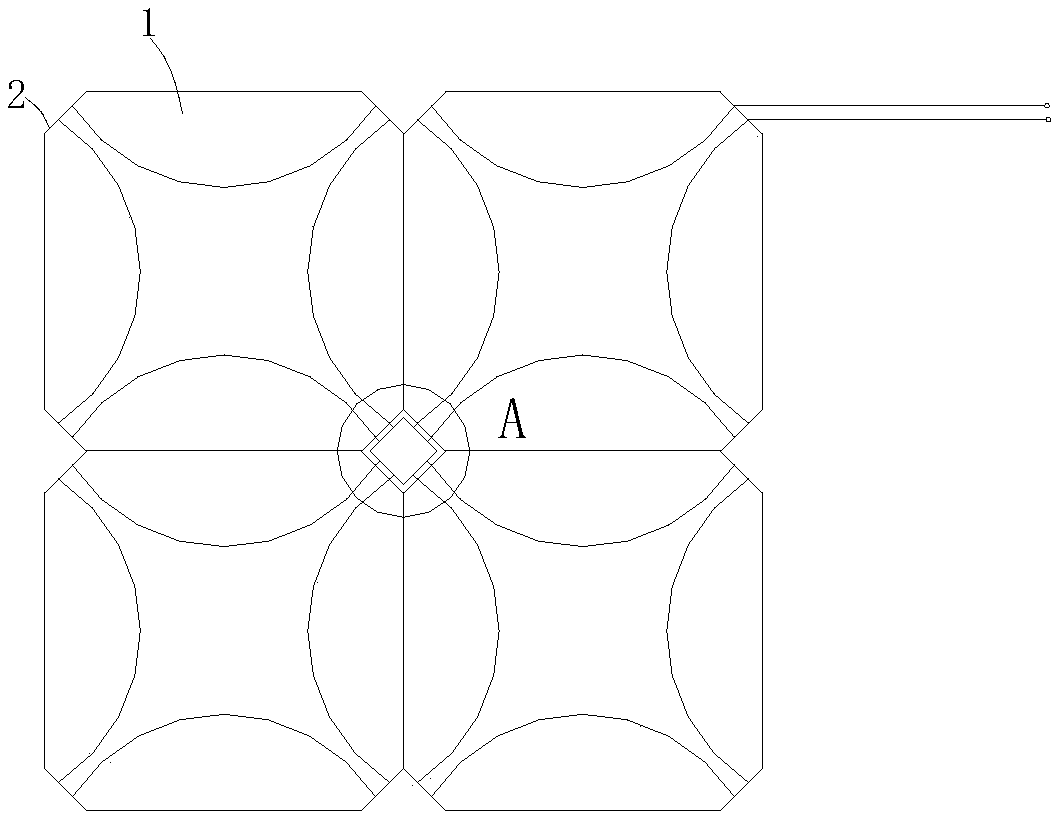

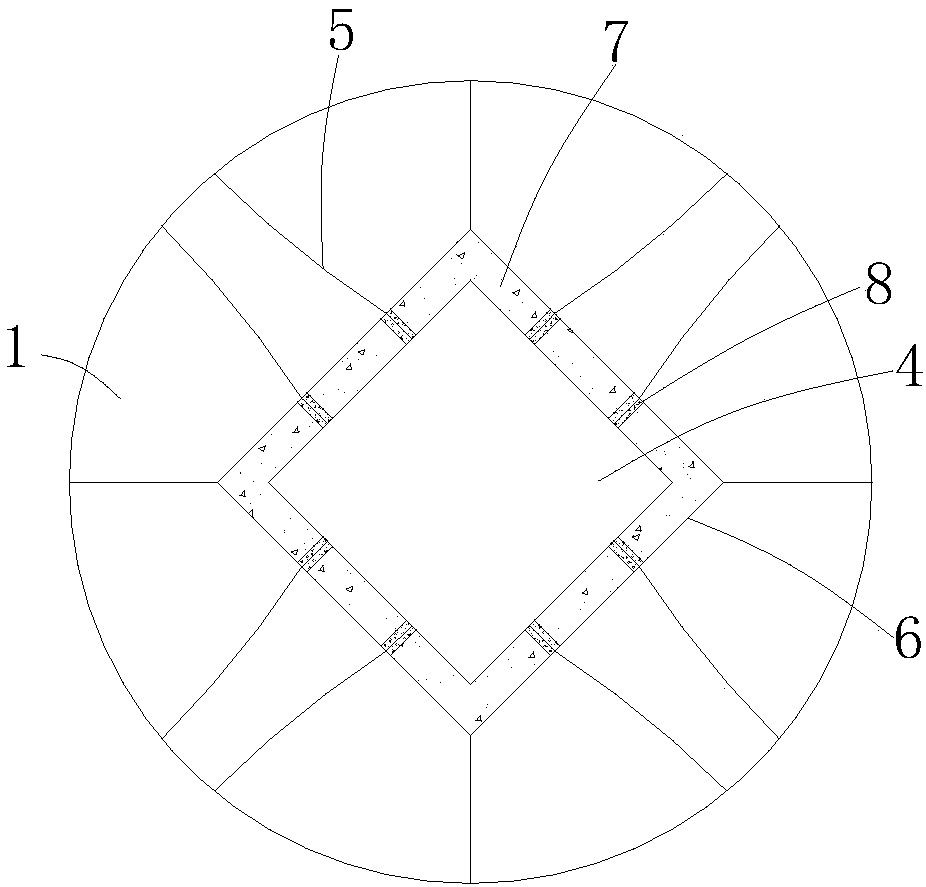

[0020] Such as figure 1 , figure 2 , image 3 As shown, an integrated electric heating tile includes a tile body unit 1 and an electric heating wire group. The four corners of the tile body unit 1 are provided with chamfers, the chamfers are the cutting surfaces 2, and the four corners of the tile body units 1 are spliced. A sealed waterproof junction box 3 is provided, and a transfer terminal (or waterproof plug-in) 4 is provided in the sealed waterproof junction box 3. The heating wire group in the tile body unit 1 is connected to the transfer terminal 4 in the sealed waterproof junction box 3.

[0021] The heating wire group includes a plurality of heating wires arranged in the tile body unit 1 , and the two free ends of the heating wires 5 pass through two adjacent cutting surfaces 2 on the tile body unit 1 .

[0022] An insulating shell 6 is arranged on the outer side of the transfer terminal 4 of the sealed waterproof junction box 3. The insulating shell 6 is square. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com