Paper box conveying mechanism adjustable in left-right interval

A conveying mechanism and adjustable technology, applied in packaging and other directions, can solve the problems of inability to transport, insufficient friction at the bottom of the carton, and achieve the effect of good protection, reducing shaking and improving friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

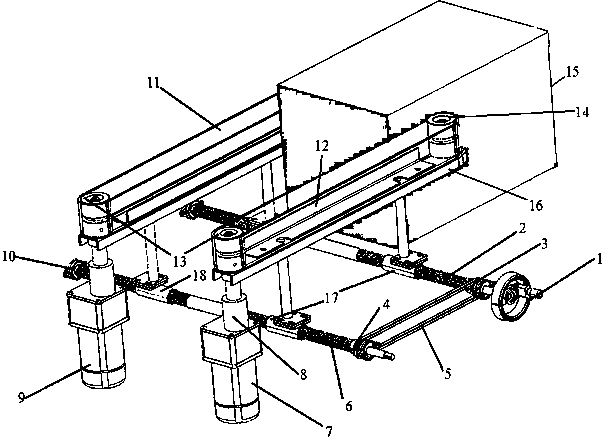

[0014] As shown in the figure, a carton conveying mechanism that can adjust the distance between left and right includes a crank handle 1, a driving screw 2, a driving sprocket 3, a driven sprocket 4, a driven screw 6, a gear motor 7, and a gear motor 9 , zinc alloy bearing 10, belt 11, belt driving wheel 13, belt driven wheel 14, left-handed screw nut 17 and right-handed screw nut 18, four zinc alloy bearings are fixed on the frame, crank handle, driving sprocket and The driven sprocket is respectively fixed on the driving screw mandrel and the driven screw mandrel through a key connection, and the two reduction motors 7 and their corresponding belt driving wheels are connected to each other through the motor flange 8, and the belt 11 is wrapped around the belt driving wheel and the belt driving wheel. Between the driven pulleys of the electric belt, a fixed sheet metal part 16 is arranged at the bottom of the belt driving pulley and the driven pulley of the electric belt, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com