Occlusion pile flat cage hoisting-placing deviation-rectifying device

A deviation-correcting device, a technology of occlusal piles, applied in the directions of transportation and packaging, load suspending elements, etc., can solve the problems of the steel cage being biased to one side of the pile, wasting labor, and increasing labor intensity, so as to ensure the thickness of the protective layer and reduce labor intensity. , the effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

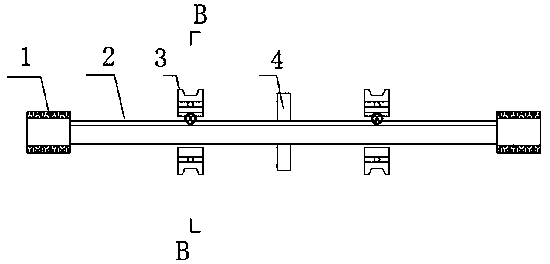

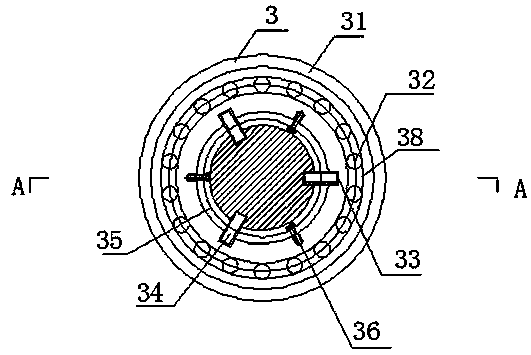

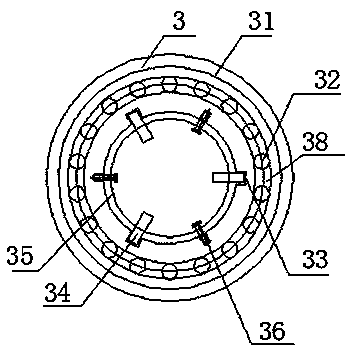

[0038] Please combine Figure 1-8 A further discussion of the present invention: a deflection correction device for hoisting and releasing a flat cage of an occlusal pile, including a rod body 2 and a sliding device 3, the rod body 2 is a cylindrical rod, and three sets of sliding grooves 21 are provided on the cross section of the rod body 2 in the axial direction The two ends of the rod body 2 are respectively provided with anti-skid layers 1, the middle part of the rod body 2 is provided with a fixed sleeve and a stopper 4, and the sliding device 3 is composed of an axial sliding bearing group 37 and a radial rotation bearing 38, The axial sliding bearing group 37 includes an annular connecting shaft 35 and auxiliary bearings 34, the auxiliary bearings 34 are provided with three groups, and the auxiliary bearings 34 are evenly distributed on the section of the annular connecting shaft 35, the radial rotation The cross section of the bearing 38 is provided with a closed groo...

Embodiment 2

[0048] Please combine Figure 9-16 The present invention is further discussed, at first, make following basic hypothesis:

[0049] During the hoisting process of the reinforcement cage 5, the uniform speed drops, that is, G=F;

[0050]The total weight of the reinforcement cage 5 is G, and the rest of the quality can be ignored;

[0051] The resultant external force of hoisting reinforcement cage 5 is F;

[0052] Upward is positive, downward is negative; leftward is positive, right is negative;

[0053] The total weight G of the reinforcement cage 5 is evenly distributed on both sides of the steel wire rope 6, that is, F1y=F2y=G / 2;

[0054] The connection point of the steel wire rope is marked as O, the intersection point of the steel wire rope and the left sliding device is marked as 0A, and the intersection point of the steel wire rope and the right sliding device is marked as 0B;

[0055] The schematic diagram of hoisting reinforcement cage 5 is as follows: Figure 9 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com