Lead-free hybrid two-dimensional double perovskite material and preparation method thereof

A double perovskite and hybrid technology is applied in the fields of material science and technology and optoelectronic applications, which can solve the problems of inability to prepare and complex systems, and achieve the effects of good chemical stability, simple synthesis method and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 0.466g bismuth oxide (Bi 2 o 3 ) and 0.340g silver nitrate (AgNO 3 ) was mixed with 5ml of hydroiodic acid, and then slowly added 0.456g of 1,4-cyclohexanediamine. Transfer the mixture into a polytetrafluoroethylene-lined stainless steel reaction kettle, place the reaction kettle in an oven at 120°C, and heat and react for 10 hours under the pressure naturally generated by the reaction kettle;

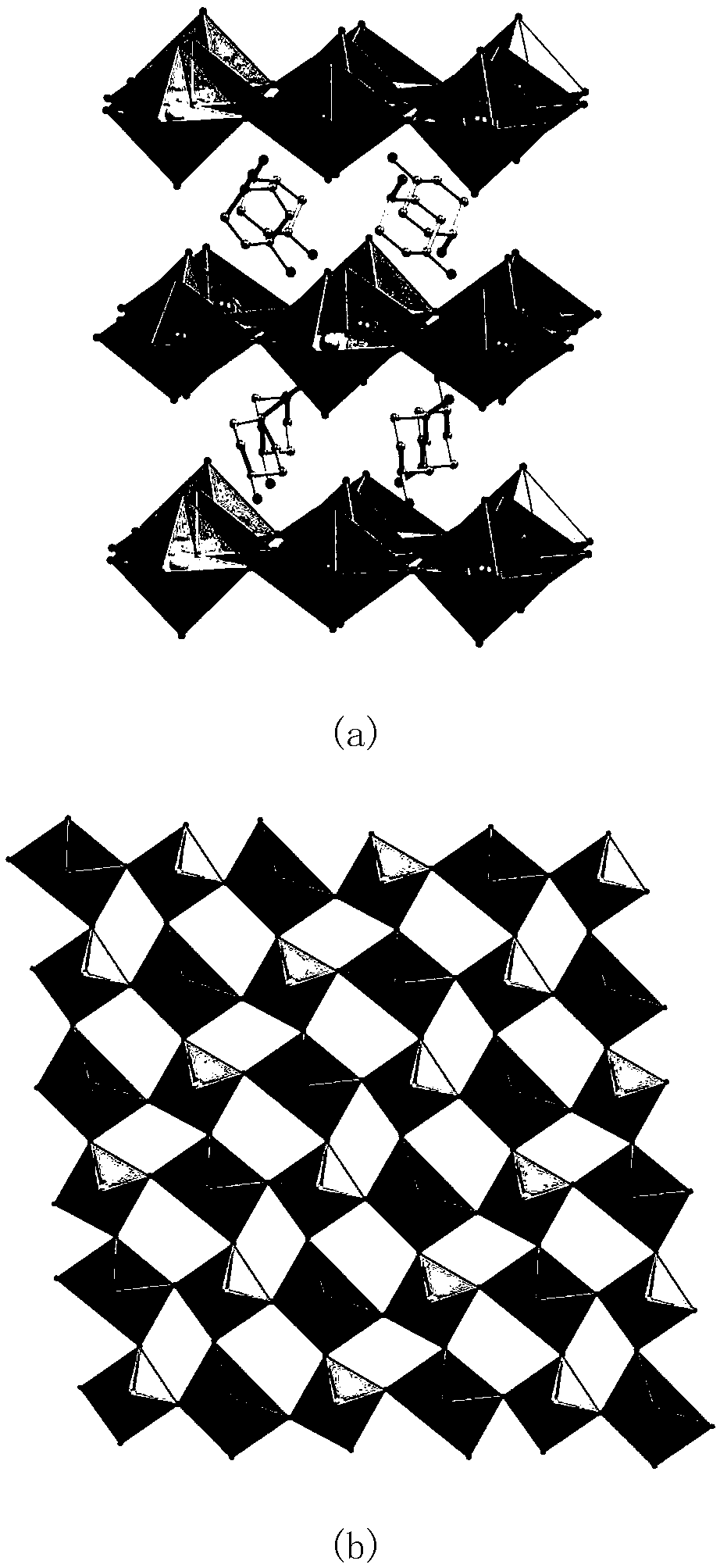

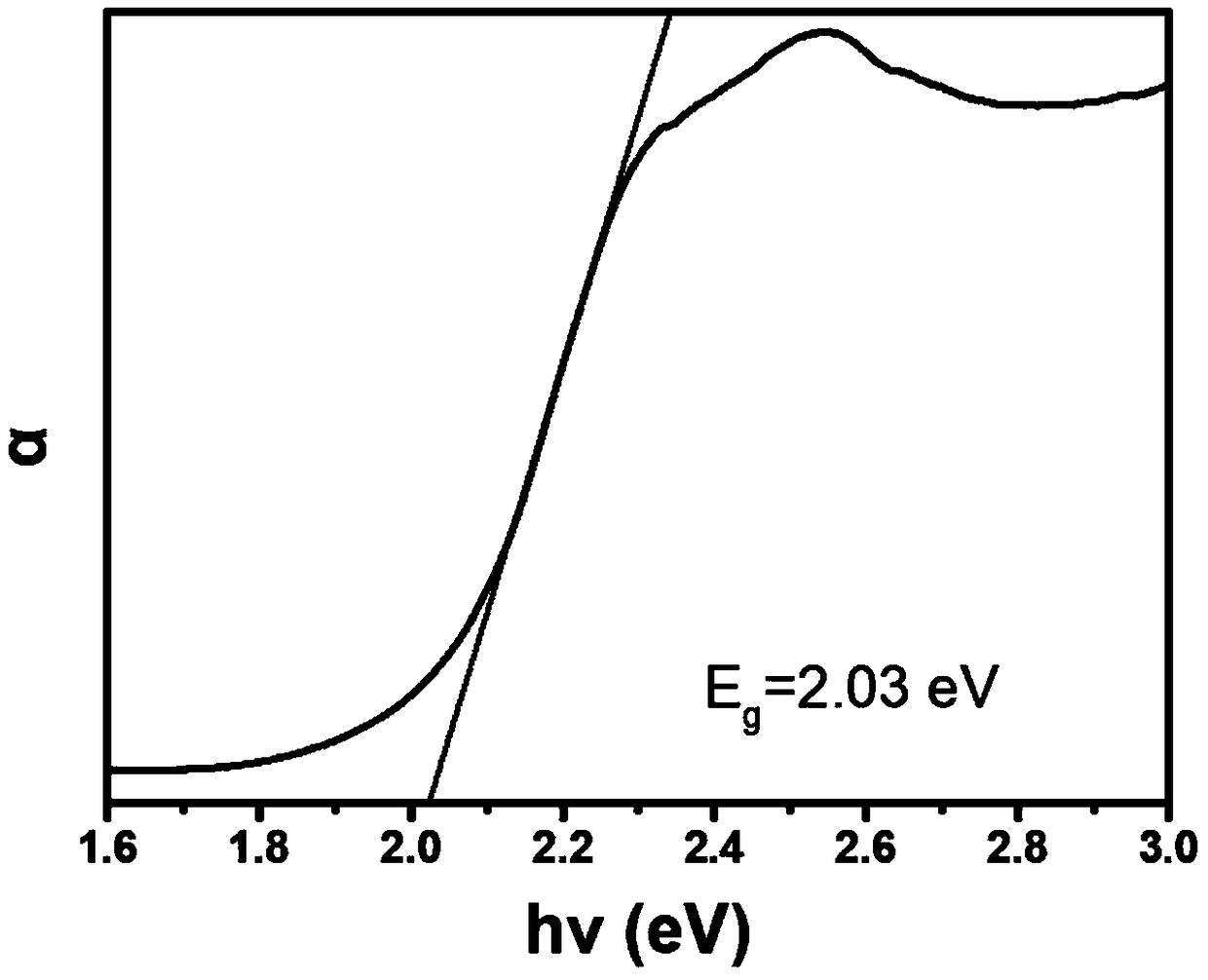

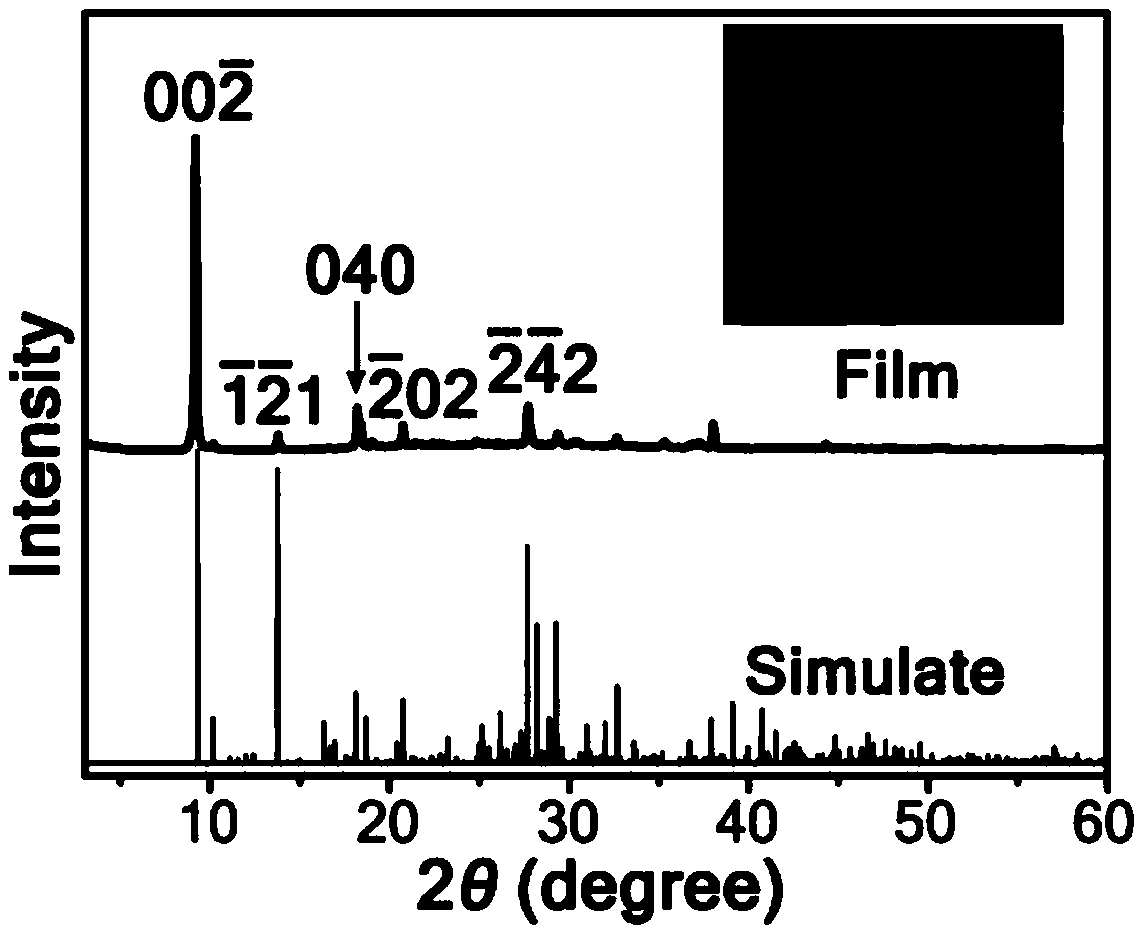

[0044] After the completion of the reaction, the reactor program was controlled to lower the temperature for 5 hours, and the crystals generated in the reactor were removed and washed 5 times repeatedly with dehydrated alcohol, dried, and finally obtained pure dark red (C 6 h 16 N 2 ) 2 BiAgI 8 Crystalline with a crystal yield greater than 95% (calculated based on Bi). The crystal contains a novel inorganic layer in the form of a two-dimensional perovskite, with spatially alternating inorganic and organic layers. The crystal structure was determined by single crystal X-r...

Embodiment 2

[0047] 0.466g bismuth oxide (Bi 2 o 3 ) and 0.380g cuprous iodide (CuI) were mixed with 5ml hydroiodic acid, and then slowly added 0.456g 1,4-cyclohexanediamine. Transfer the mixture into a polytetrafluoroethylene-lined stainless steel reaction kettle, place the reaction kettle in an oven at 130°C, and heat and react for 10 hours under the pressure naturally generated by the reaction kettle;

[0048] After the completion of the reaction, the reactor program was controlled to lower the temperature for 5 hours, and the crystals generated in the reactor were removed and washed 5 times repeatedly with dehydrated alcohol, dried, and finally obtained pure red-black (C 6 h 16 N 2 ) 2 BiCuI 8 Crystalline with a crystal yield greater than 90% (calculated based on Bi). The crystal and (C 6 h 16 N 2 ) 2 BiAgI 8 The crystals are similar, containing a novel 2D perovskite form of inorganic layers with spatially alternating inorganic and organic layers. The crystal structure was ...

Embodiment 3

[0051] 0.466g bismuth oxide (Bi 2 o 3 ) and 0.380g cuprous iodide (CuI) mixed with 5ml hydroiodic acid, then slowly added 0.792g cyclohexylamine. Transfer the mixture into a polytetrafluoroethylene-lined stainless steel reaction kettle, place the reaction kettle in an oven at 130°C, and heat and react for 10 hours under the pressure naturally generated by the reaction kettle;

[0052] After the completion of the reaction, the reactor program was controlled to lower the temperature for 5 hours, and the crystals generated in the kettle were removed and then repeatedly suction-filtered with sherwood oil, dried, and finally obtained pure (C 6 h 14 N) 4 BiCuI 8 Crystalline with a crystal yield greater than 90% (calculated based on Bi). The concrete contains a novel structure in which two-dimensional inorganic layers and base layers are alternately arranged. The crystal structure was determined by single crystal X-ray diffraction analysis, and the phase purity was determined b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Optical bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com