Bromobutyl rubber stopper for freeze-drying additives and preparation method thereof

A technology of bromobutyl rubber and additives, which is applied in the field of polymer materials, can solve problems such as unsatisfactory performance, and achieve the effects of reducing quantity, increasing internal lubricity, and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

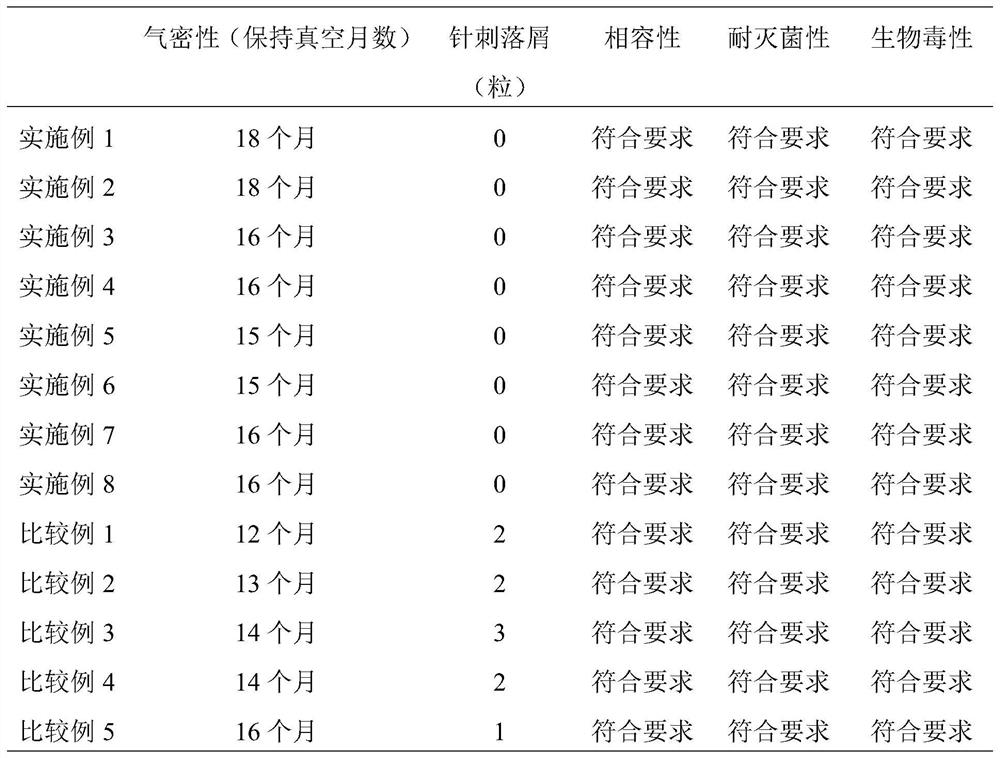

Examples

preparation example Construction

[0013]This embodiment also provides a preparation method of the bromobutyl rubber stopper, including the following steps:

[0014]Ingredients → mixing → pre-forming → vulcanization → punching → cleaning and siliconization → packaging, the specific methods are as follows:

[0015](1) Prepare materials in parts by weight;

[0016](2) Under normal temperature and pressure, after adding BIIR2030 to the internal mixer for mixing for 1 to 2 minutes, adding calcined kaolin for mixing for 3 to 4 minutes, then adding talc, carbon black, PE wax, magnesium oxide and HY-2055 for mixing. Mix for 4~5min, discharge at 125~135℃ after mixing; put the rubber discharged from the internal mixer into the open mixer, pull the knife and cool the rubber twice on the open mixer, and add the oxidation Zinc and sulfur, mixing for 3~4min, mashing and mixing>6min, the temperature during the smelting process is 70~85℃, and the lower piece is cooled for 2~3min;

[0017](3) Put the cooled mixed rubber into the extruder, the e...

Embodiment 1

[0024]Example 1 of the present invention provides a bromobutyl rubber stopper, including the following components in parts by weight: 100 parts of BIIR2030, 60 parts of calcined kaolin, 14 parts of talc, 4 parts of carbon black, 0.4 parts of HY-2055 resin, 0.5 parts of sulfur, 1.4 parts of magnesium oxide, 4 parts of zinc oxide and 1 part of PE wax.

[0025]It is prepared by the following method:

[0026](1) Prepare materials in parts by weight;

[0027](2) Under normal temperature and pressure, after adding BIIR2030 to the internal mixer for mixing for 1 to 2 minutes, adding calcined kaolin for mixing for 3 to 4 minutes, then adding talc, carbon black, PE wax, magnesium oxide and HY-2055 for mixing. Mix for 4 to 5 minutes, and discharge the material at 130°C after mixing; put the rubber discharged from the internal mixer into the open mixer, pull the rubber on the open mixer 2 times, add zinc oxide and Sulfur, mixing for 3 to 4 minutes, mashing and mixing for 8 minutes, the temperature is 8...

Embodiment 2

[0033]Example 2 of the present invention provides a bromobutyl rubber stopper, including the following components in parts by weight: 100 parts of BIIR2030, 60 parts of calcined kaolin, 16 parts of talc, 5 parts of carbon black, 0.6 parts of HY-2055 resin, 0.7 parts of sulfur, 1.6 parts of magnesium oxide, 5 parts of zinc oxide and 0.6 parts of PE wax.

[0034]It is prepared by the following method:

[0035](1) Prepare materials in parts by weight;

[0036](2) Under normal temperature and pressure, after adding BIIR2030 to the internal mixer for mixing for 1 to 2 minutes, adding calcined kaolin for mixing for 3 to 4 minutes, then adding talc, carbon black, PE wax, magnesium oxide and HY-2055 for mixing. Mix for 4 to 5 minutes, and discharge at 125°C after mixing; put the rubber discharged from the internal mixer into the open mixer, pull the rubber on the open mixer 2 times, add zinc oxide and Sulfur, mixing for 3 to 4 minutes, mashing and mixing for 7 minutes, the temperature is 85°C during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com