A kind of radiation-curable black light-shielding adhesive composition

A technology of radiation curing and composition, applied in the field of black light-shielding adhesive composition, can solve the problems of difficulty in overcoming the black deep curing problem, the light-colored adhesive cannot achieve the light-shielding effect, and cannot meet the needs of high-pixel imaging, and the like, Achieve the effect of facilitating dispensing production operations, solving deep curing problems, and facilitating efficient initiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

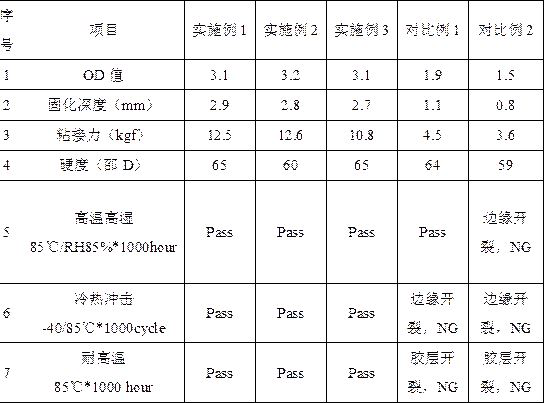

Examples

Embodiment 1

[0038] This embodiment provides a radiation-curable black light-shielding adhesive composition, which contains components and the percentages of each component are as follows:

[0039] Mercaptan-modified hyperbranched vinyl ether resin (self-made) 65%

[0040] Aliphatic epoxy resin 10%

[0041] 3,4-Epoxycyclohexylcarboxylate 15%

[0042] Sulfonium salt 2%

[0043] Nano calcium carbonate 1%

[0044] EVONIK TD788A carbon black 3%

[0045] Aminopropylamine Dioleate 2.5%

[0046] Gamma-Methacryloxypropyltrimethoxysilane 1.5%.

[0047] The mercaptan-modified hyperbranched vinyl ether resin is self-made, and by weight percentage, the materials required for the resin synthesis reaction are:

[0048] 1,4-Cyclohexanedimethanol divinyl ether: 65%

[0049] Polymercapto-functional compounds: 34.8%

[0050] Catalyst: 0.2%.

[0051] The preparation method of described mercaptan modified hyperbranched vinyl ether resin comprises the following specific steps,

[0052] Step 1: prepar...

Embodiment 2

[0055] A radiation-curable black light-shielding adhesive composition, by weight percentage, containing components and each component

[0056] The percentage content is as follows:

[0057] Mercaptan-modified hyperbranched vinyl ether resin (self-made) 45%

[0058] Aliphatic epoxy resin EPOLEAD GT401 15%

[0059]Bis((3,4-epoxycyclohexyl)methyl)adipate 20%

[0060] 3,4-Epoxycyclohexylmethylmethacrylate 10%

[0061] Diaryliodonium salt 1.5%

[0062] Alkylsulfonium salt 1%

[0063] Polyester microparticles 1.7%

[0064] EVONIK N600 Carbon Black 3%

[0065] Oleyl amino oleate 0.3%

[0066] Vinyltriisopropoxysilane 1%

[0067] 3-Methacryloxypropyltrimethoxysilane 1.5%.

[0068] The mercaptan-modified hyperbranched vinyl ether resin is self-made, and by weight percentage, the materials required for the resin synthesis reaction are:

[0069] DVE-3: 50%.

[0070] TEMPIC: 49.7%.

[0071] Catalyst: 0.3%.

[0072] The catalyst is n-PrNH2.

[0073] The preparation method of ...

Embodiment 3

[0077] A radiation-curable black light-shielding adhesive composition, by weight percentage, containing components and each component

[0078] The percentage content is as follows:

[0079] Mercaptan modified hyperbranched vinyl ether resin (self-made) 50%

[0080] Aliphatic epoxy resin EPOLEAD GT401 10%

[0081] Aliphatic epoxy resin CELLOXIDE 2081 10%

[0082] 1,2-Epoxy-4-vinylcyclohexane 10%

[0083] 3,4-Epoxycyclohexylmethacrylate 10%

[0084] Diaryliodonium salt 2%

[0085] Polyester microparticles 1%

[0086] Talc 2%

[0087] EVONIK N600 Carbon Black 2%

[0088] Alkyl quaternary ammonium salt 0.5%

[0089] Methacryloxytrimethoxysilane 1%

[0090] Phenyltrimethoxysilane 1.5%.

[0091] The mercaptan-modified hyperbranched vinyl ether resin is self-made in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com