Method for preparing 3D wig by warp knitting spacer fabrics with different thicknesses

A technology of warp-knitting spacer fabrics and wigs, which is applied to warp knitting, wigs, flat warp knitting machines, etc., can solve the problems of low production efficiency, numerous production processes, time-consuming and labor-intensive, etc., and achieve the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

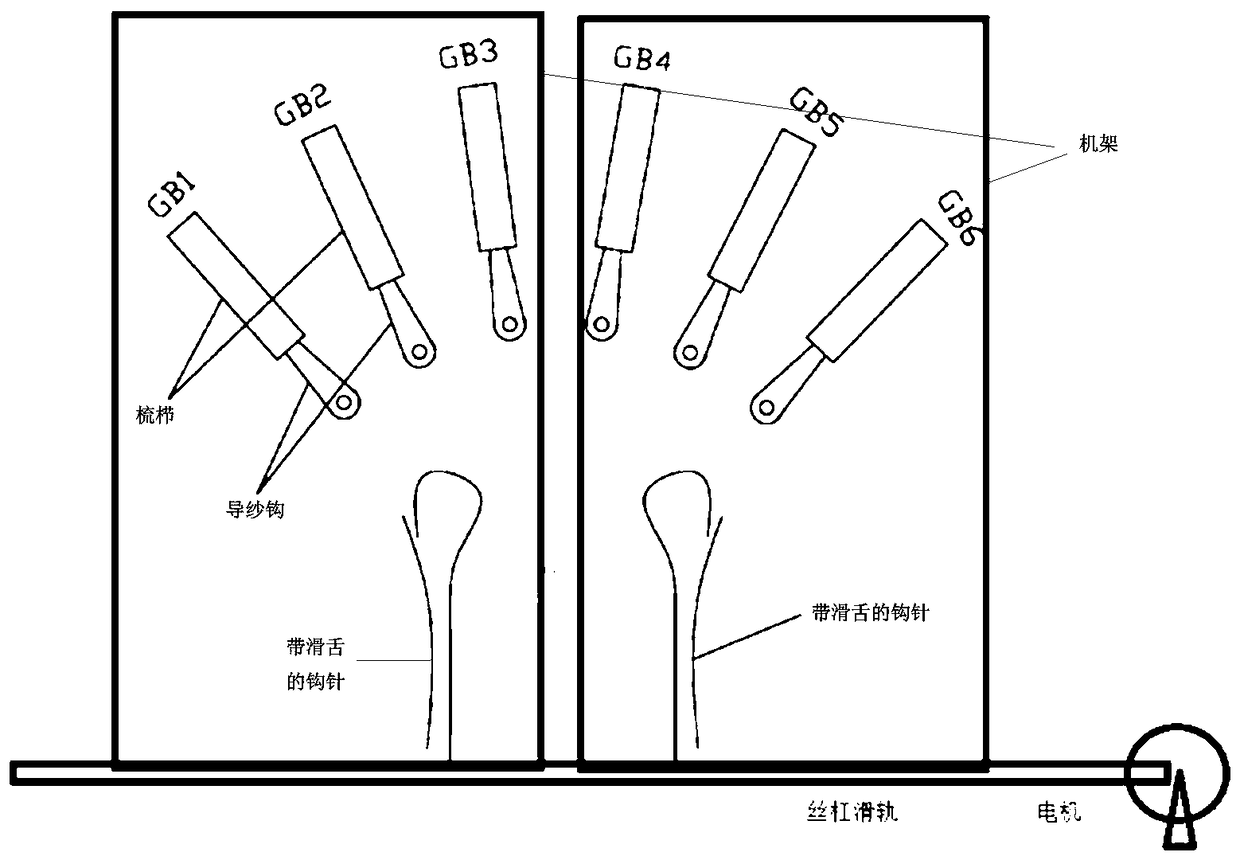

[0021] The method for preparing a 3D wig by warp knitting spacer fabrics with different thicknesses, according to the design, adopts six bar knitting on a double needle bed warp knitting machine, comprising the following steps:

[0022] (1) Bars GB1 and GB2 penetrate the yarn of the upper wig base fabric, bars GB5 and GB6 penetrate the yarn of the wig base fabric on the opposite side, and bars GB3 and GB4 penetrate the wig silk;

[0023] (2) The base fabric of the wig is woven by bars GB1 and GB2, the base fabric of the opposite wig is woven by bars GB5 and GB6; the wig is woven by bars GB3 and GB4;

[0024] (3) When changing the thickness in the horizontal direction from 5 cm to 35 cm, and then from 35 cm to 5 cm, set the combs GB3 and GB4 to complement each other to wear wigs according to the program, and the amount of wigs to be worn is equal. The bar GB3 is worn first and then empty, and the bar GB4 is empty before being worn; the let-off amount of the bar GB3 is set to be...

Embodiment 2

[0027] The method for preparing 3D beards by warp knitting spacer fabrics with different thicknesses, according to the design, adopts six bar knitting on a double needle bed warp knitting machine, including the following steps:

[0028] (1) Bars GB1 and GB2 penetrate the yarn of the upper wig base fabric, bars GB5 and GB6 penetrate the yarn of the wig base fabric on the opposite side, and bars GB3 and GB4 penetrate the wig silk;

[0029] (2) The base fabric of the wig is woven by bars GB1 and GB2, the base fabric of the opposite wig is woven by bars GB5 and GB6; the wig is woven by bars GB3 and GB4;

[0030] (3) When changing the thickness from 5 cm to 35 cm in the longitudinal direction, and then gradually from 35 cm to 5 cm, set the combs GB3 and GB4 to complement the wigs according to the program, and the amount of wigs to be worn is equal. The bar GB3 is worn first and then empty, and the bar GB4 is empty before being worn; the let-off amount of the bar GB3 is set to be sm...

Embodiment 3

[0033] The method for preparing 3D eyebrows by warp knitting spacer fabrics with different thicknesses, according to the design, adopts six bar knitting on a double needle bed warp knitting machine, including the following steps:

[0034] (1) Bars GB1 and GB2 penetrate the yarn of the upper wig base fabric, bars GB5 and GB6 penetrate the yarn of the wig base fabric on the opposite side, and bars GB3 and GB4 penetrate the wig silk;

[0035] (2) The base fabric of the wig is woven by bars GB1 and GB2, the base fabric of the opposite wig is woven by bars GB5 and GB6; the wig is woven by bars GB3 and GB4;

[0036] (3) When changing the thickness in the horizontal direction from 1 cm to 2 cm, and then from 2 cm to 1 cm, set the combs GB3 and GB4 to complement each other to wear wigs according to the program, and the amount of wigs to be worn is equal. The bar GB3 is worn first and then empty, and the bar GB4 is empty before being worn; the let-off amount of the bar GB3 is set to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com