Pile foundation structure breakwater with energy dissipation chamber

A technology for energy dissipation chambers and breakwaters, which is applied in the direction of breakwaters, embankments, jetties, etc. It can solve the problems that the wave baffle is not a hollow structure, the elevation of the top of the structure increases, and occupies a large area of the sea area, so as to achieve low construction difficulty and reduce the impact force , The effect of occupying a small area of sea area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

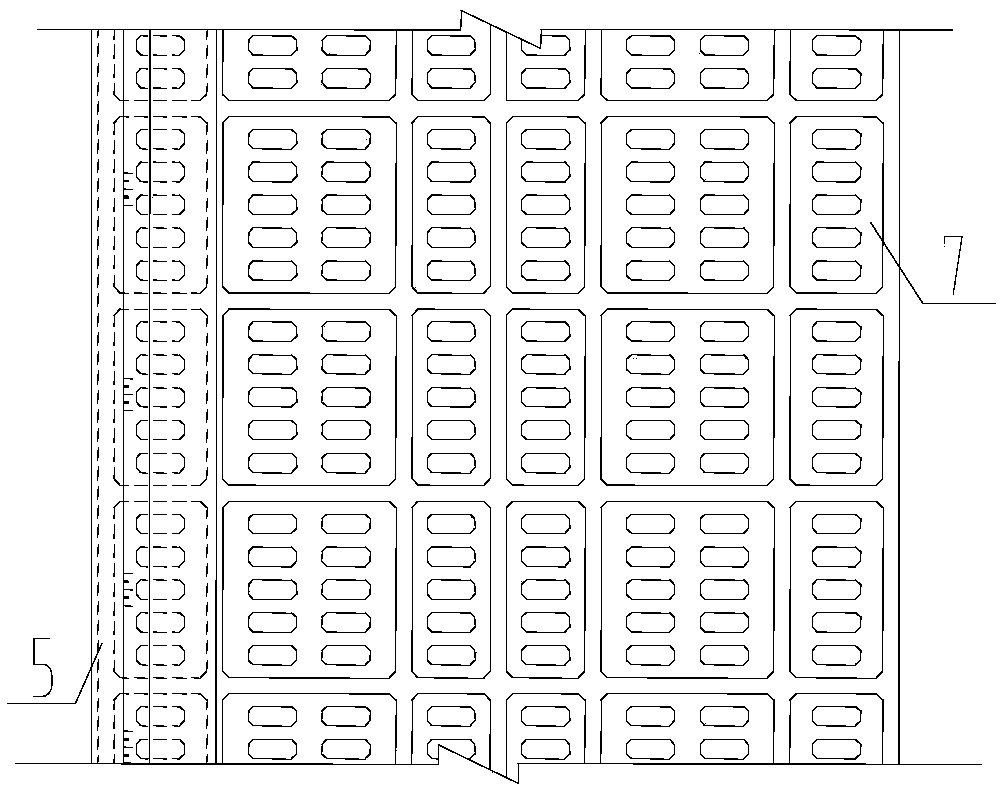

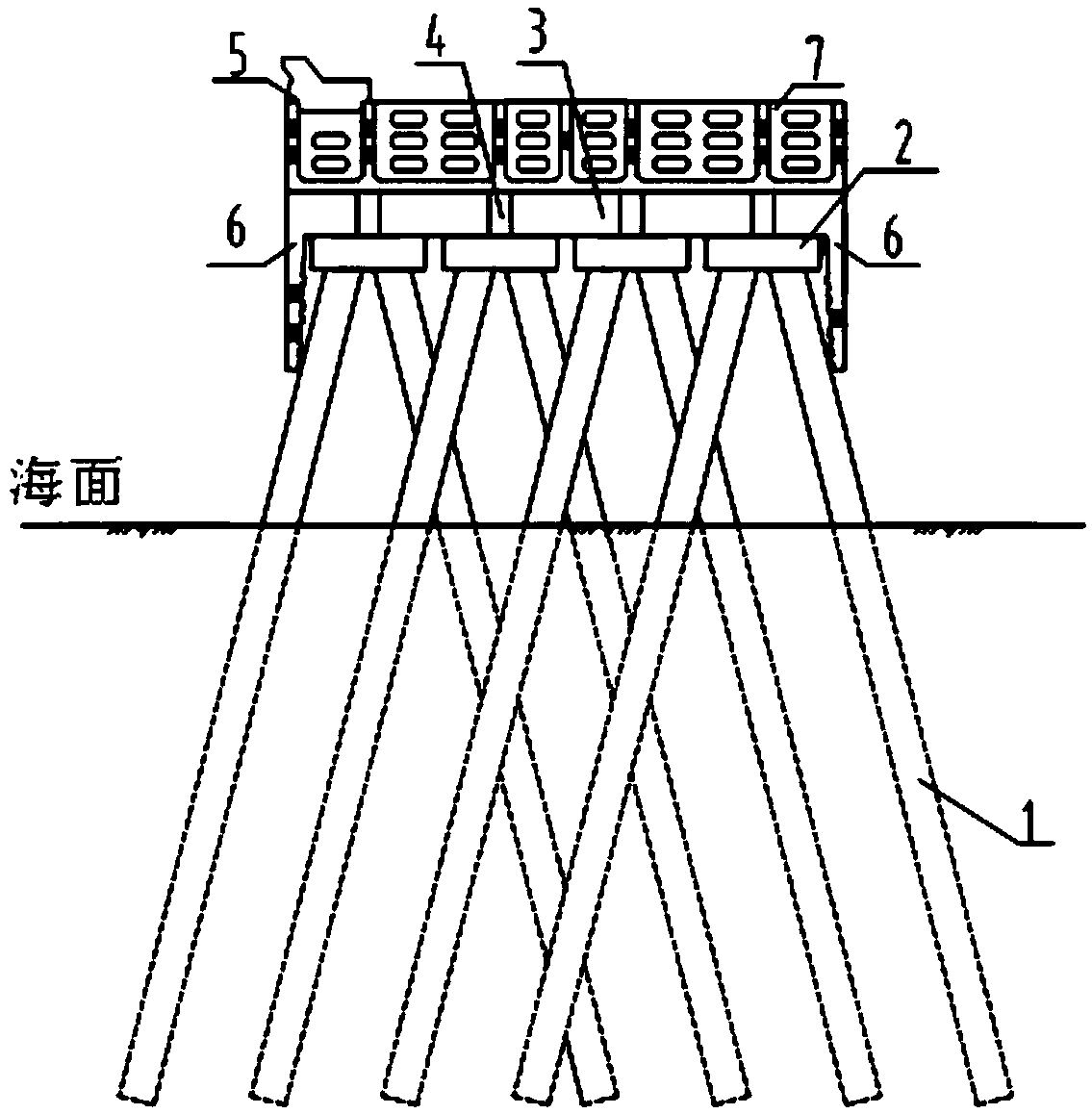

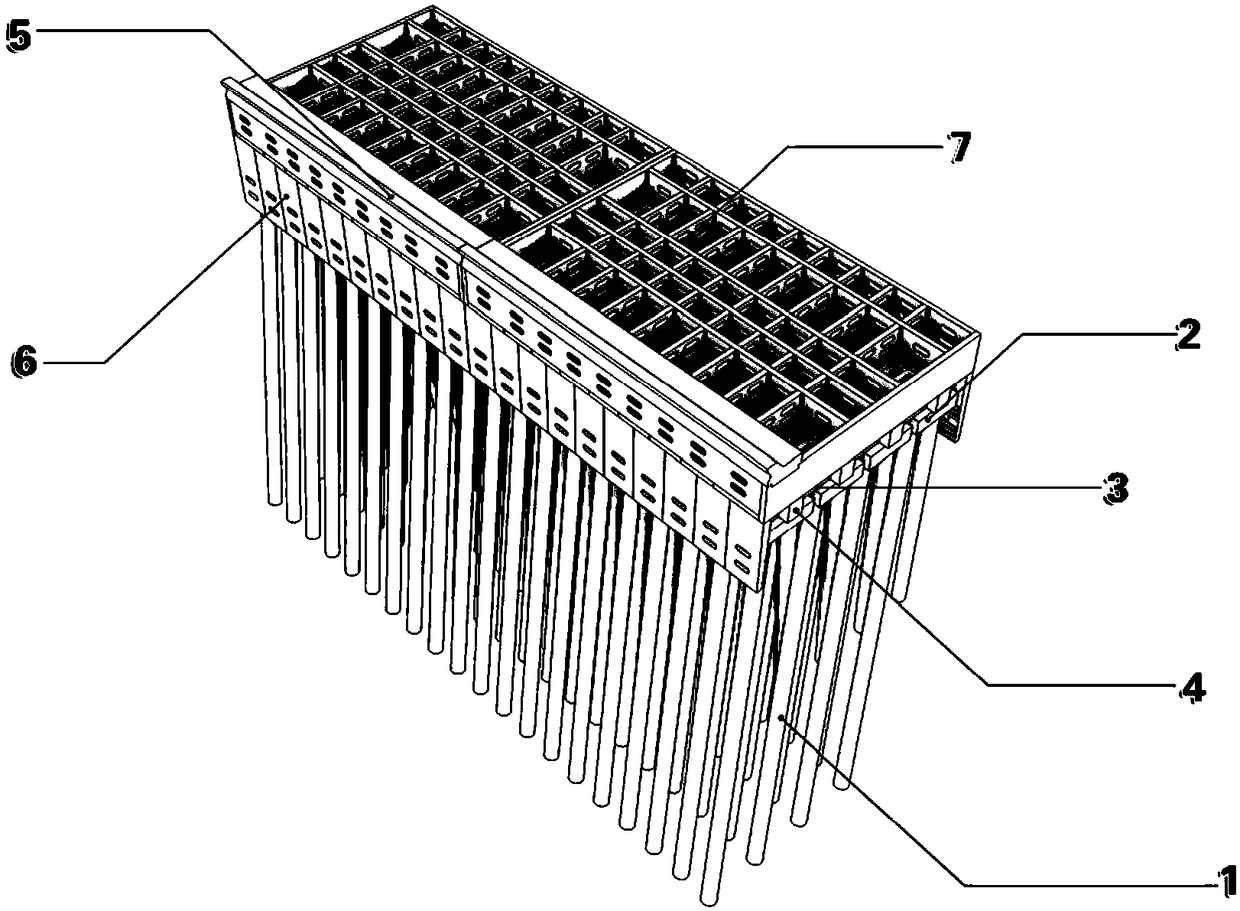

[0017] Such as figure 1 and figure 2 The shown pile foundation structure breakwater with energy dissipation chamber is composed of pile foundation 1, pile foundation cap 2, beam 3, longitudinal beam 4, wave retaining wall 5, wave retaining plate 6, and energy dissipation chamber 7. Pile body 1 is a steel pipe pile with a diameter of 1.5m, a wall thickness of 16mm, a pile length of 35m, a pile top elevation of -2.5m, and a slope of the pile body of 4:1; the cap is 1.5m thick, prefabricated, and cast-in-place at the connection with the pile; The height of the prefabricated transverse and longitudinal beams is 2m, and they are lapped vertically and horizontally on the caps, and then cast-in-place, and the transverse and longitudinal beams, caps and piles are connected into a whole through the reserved steel bars on the caps; the wave baffles are prefabricated, similar to the installation method of the longitudinal beams ;The upper part of the transverse and longitudinal beams i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com