Carbon nano tube fiber yarn composite thermal expansion material type laser photo-thermal driver

A carbon nanotube fiber, thermally expandable material technology, used in yarns, machines/engines, mechanisms that generate mechanical power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

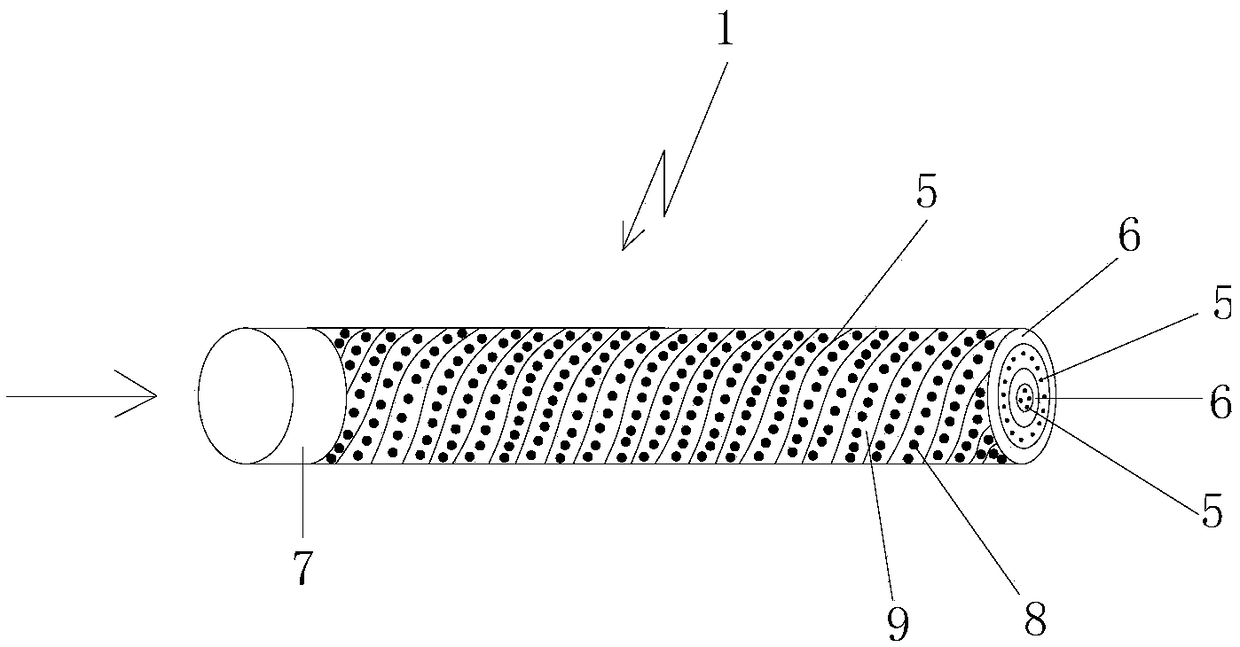

[0032] Carbon nanotube fiber yarn winding thermal expansion material multi-layer stacked laser photothermal driver 1

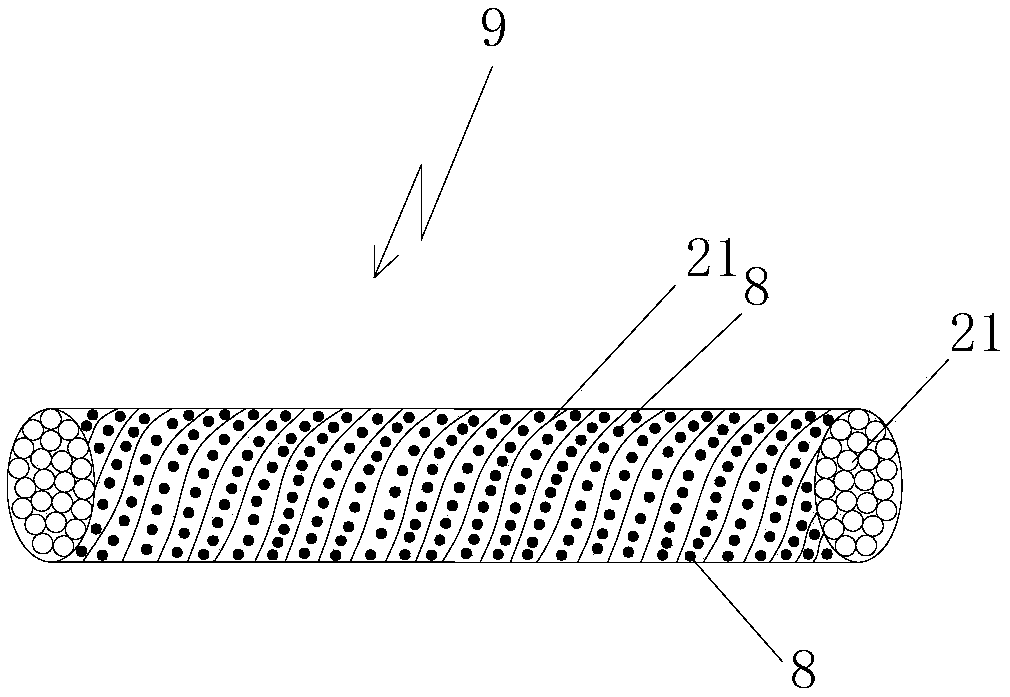

[0033] Schematic diagram of the structure of the carbon nanotube fiber yarn winding thermal expansion material multi-layer stacked laser photothermal driver 1 in Example 1 of the present invention (see figure 1 ); Nanoparticle composite carbon nanotube fiber yarn structure schematic diagram (see image 3 ).

[0034] In Example 1 of the present invention, the carbon nanotube fiber yarn is wound with thermal expansion material multi-layer stacked laser photothermal driver 1 (see figure 1 ), including: nanoparticle composite carbon nanotube fiber yarn spiral winding layer 5, first thermal expansion material layer 6, first laser receiver 7, laser; first thermal expansion material layer 6 uses: organic polymer thermal expansion material; nano Particle composite nanoparticle composite carbon nanotube fiber yarn 9 (see image 3 ) uses the method of assembling or c...

Embodiment 2

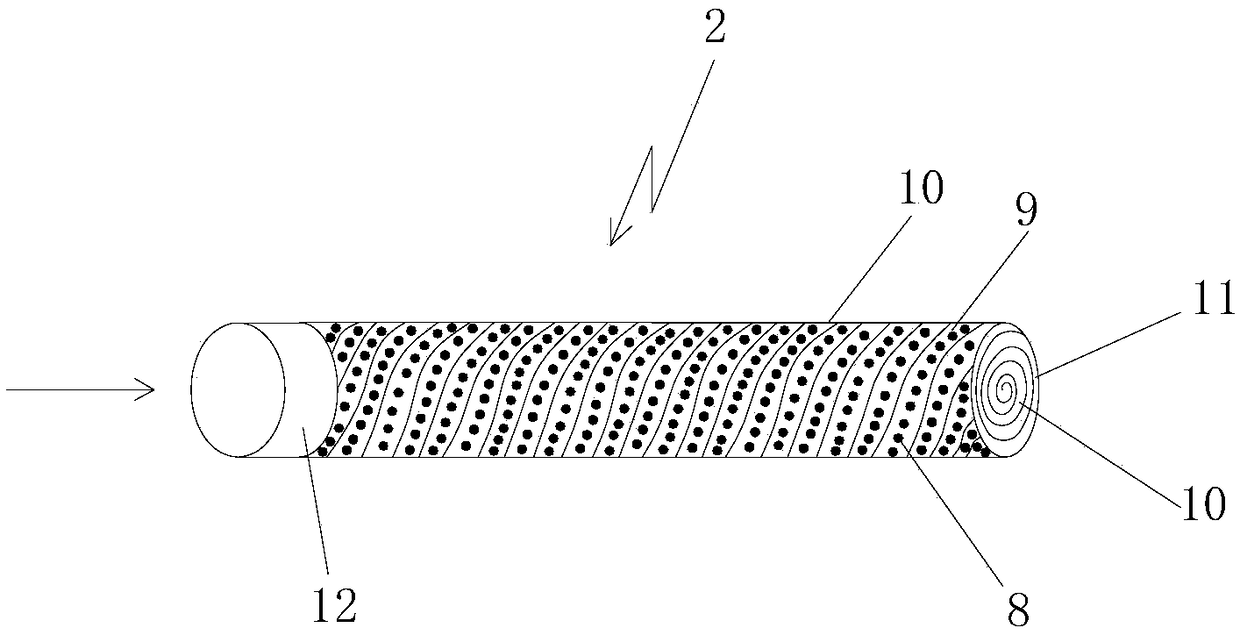

[0037] Carbon nanotube fiber yarn spinning and thermal expansion material layer stacked spiral laser photothermal driver 2

[0038] The carbon nanotube fiber yarn spun cloth and the thermal expansion material layer stacked in Example 2 of the present invention are a structural schematic diagram of a spiral laser photothermal driver 2 (see figure 2 ); Nanoparticle composite carbon nanotube fiber yarn 9 structural representations (see image 3 ).

[0039]The carbon nanotube fiber yarn spun fabric and thermal expansion material layer stacked spiral laser photothermal driver 2 in Example 2 of the present invention includes: nanoparticle composite carbon nanotube fiber yarn spun fabric 10, the second thermal expansion material layer 11, the second 2. Laser receiver 12, laser device; thermal expansion material 11 adopts liquid thermal expansion material microcapsules, including: adopting an elastic material film with good thermal conductivity to coat liquid thermal expansion mater...

Embodiment 3

[0042] Carbon nanotube fiber yarn composite thermal expansion material cylindrical spring core laser photothermal driver 3

[0043] Schematic diagram of the structure of the carbon nanotube fiber yarn composite thermal expansion material cylindrical spring core type laser photothermal driver 3 in Example 3 of the present invention (see Figure 4 ); Nanoparticle composite carbon nanotube fiber yarn 9 structural representations (see image 3 ); nanoparticle composite carbon nanotube fiber yarn helical spring layer 13 structural representation (see Figure 5 ).

[0044] Carbon nanotube fiber yarn composite thermal expansion material cylindrical spring core laser photothermal driver 3, including: nanoparticle composite carbon nanotube fiber yarn helical spring layer 13, thermal expansion material cylinder layer 14, nanoparticle composite carbon nanotube Fiber yarn winding layer 15, third laser receiver 16, laser; thermal expansion material 14 adopts: organic polymer thermal expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com