Drying device of clamping heat conduction type film laminating machine

A drying device and heat conduction technology, applied in the direction of coating, etc., can solve the problems of inconvenient disassembly and cleaning, uneven heating, poor connection, etc., and achieve the effects of quick maintenance, improved sufficiency, and uniform heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

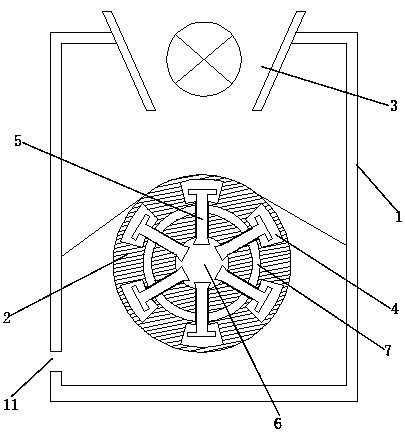

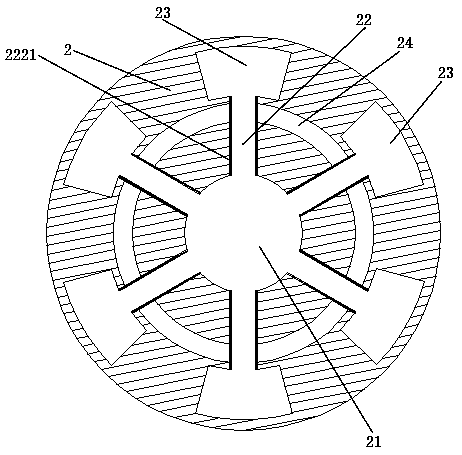

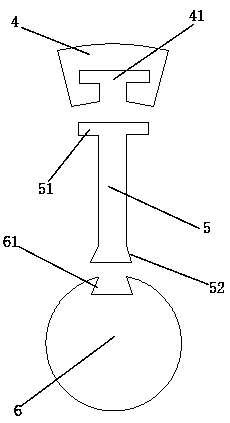

[0022] Such as Figures 1 to 5 As shown in the figure, a clamping heat conduction type laminating machine drying device includes a drying box 1 , a heating roller 2 , a heat conducting block 4 , a heat transfer plate 5 , a heating block 6 , and an air induction mechanism 3 . The heating roller 2 is installed inside the drying box 1; the air induction mechanism 3 is installed at the upper end of the drying box 1; the bottom side of the drying box 1 is provided with a vent 11. Such as figure 2 As shown, one end of the heating roller 2 extends axially from the middle to the inside with a heating groove 21; one end of the heating roller 2 extends axially from the periphery to the inside with a plurality of heat conduction grooves 23; the heat conduction grooves 23 are evenly distributed around the heating roller 2; multiple heat transfer grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com