Control method for synchronizing rotating speed in power upshift of wet-type double clutch automatic transmission

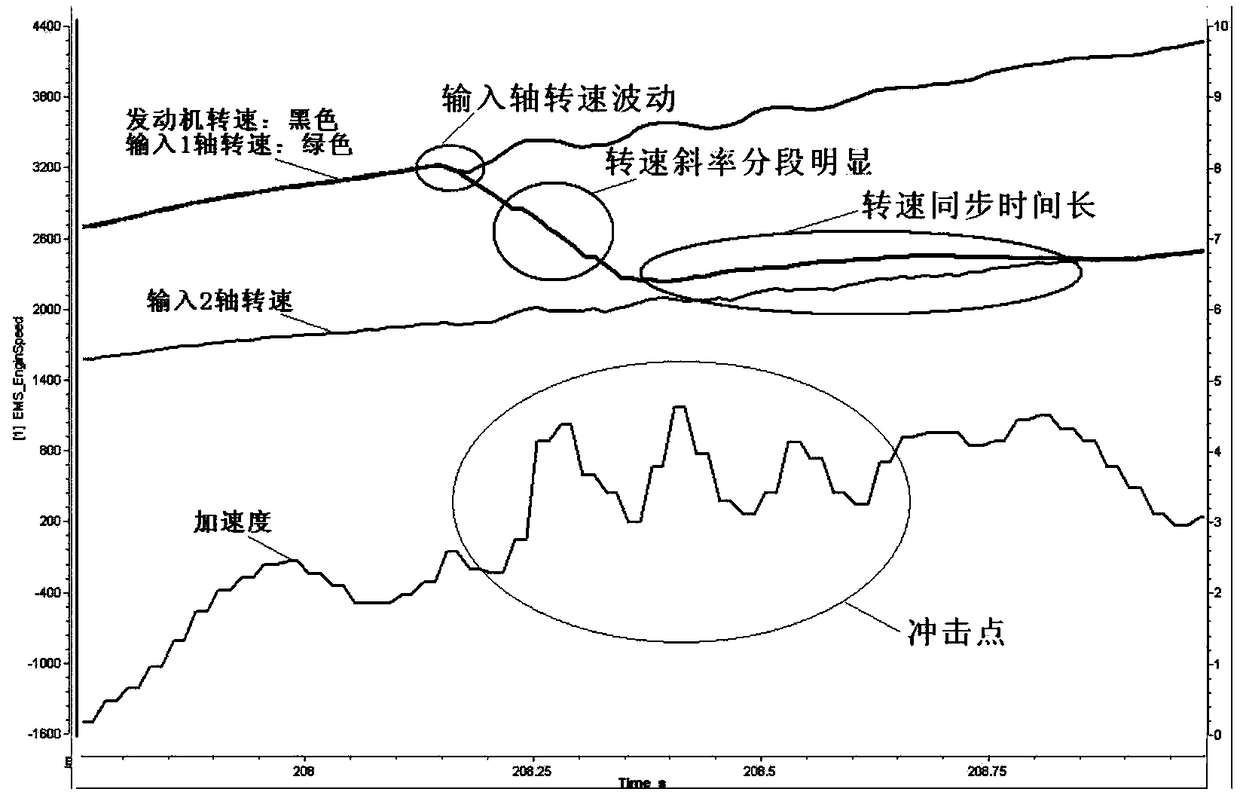

A technology of wet dual clutch and automatic transmission, which is applied in transmission control, geared components, belts/chains/gears, etc. It can solve problems such as long synchronization time, shifting impact, and long-term slipping of clutches, etc., to achieve Improve driving experience, resolve shocks, and increase system robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, further describe the present invention in detail:

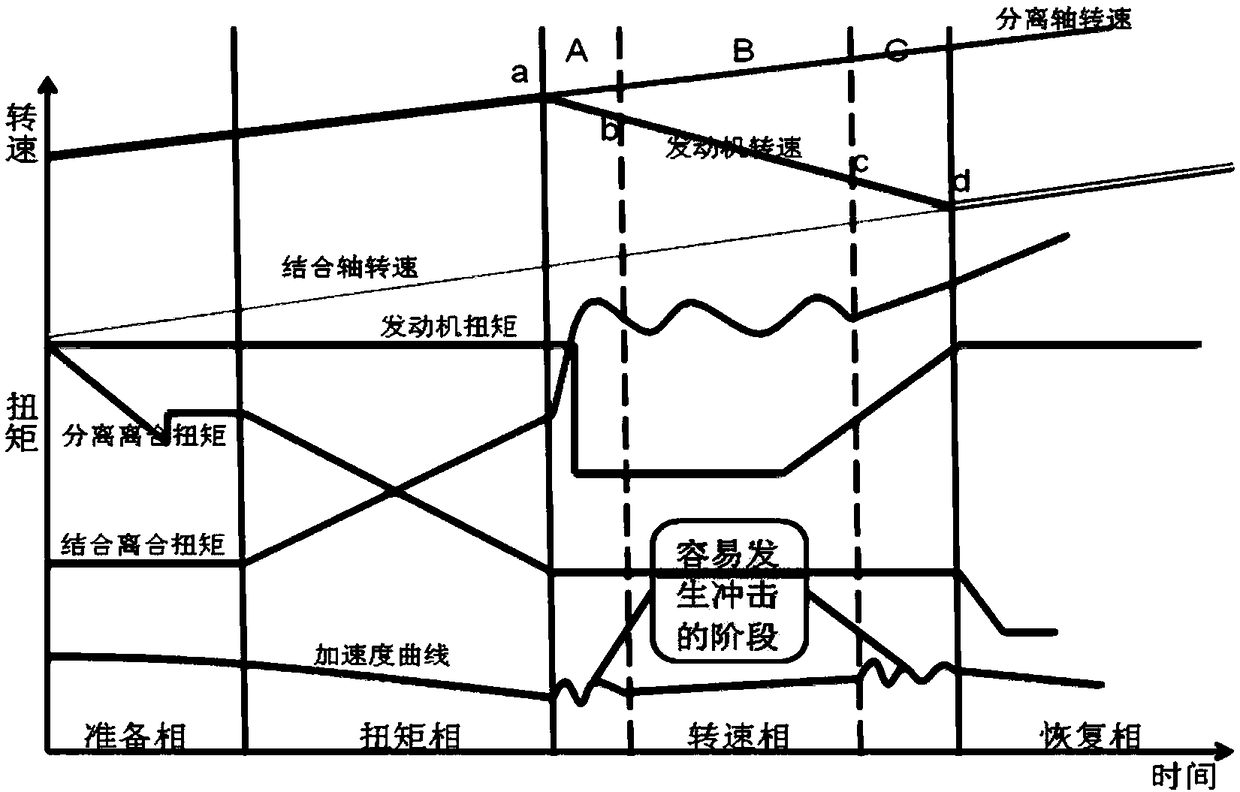

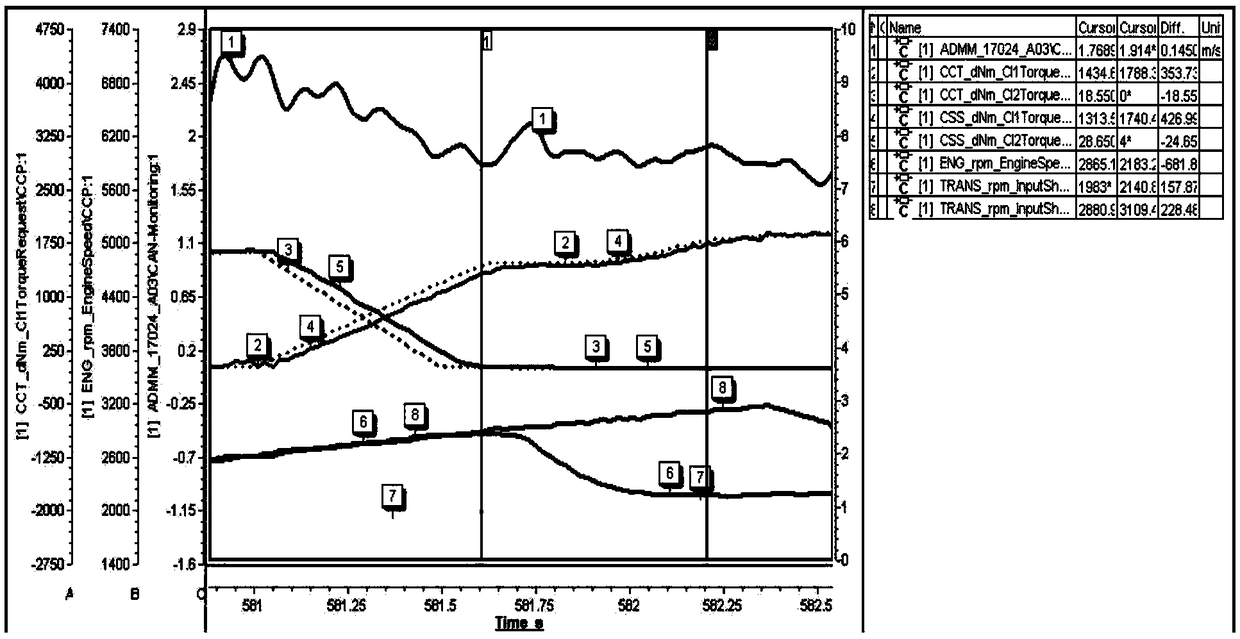

[0025] The target of power upshift speed phase control is to realize the engine speed drop from disengagement clutch speed to synchronize with the engagement clutch speed. In order to achieve speed synchronization quickly and smoothly, the present invention realizes it through engine torque request and clutch torque control. It mainly includes the control of two major plates

[0026] 1. Clutch control

[0027] The clutch control method is used to control the engine speed to switch from the disengaged shaft to the engaged shaft with a certain slope. Use curve control to control engaging the clutch during power upshifts. Curve control has the following stages:

[0028]

[0029] Table 1 Speed Phase PID Curve Control

[0030] 2. Engine torque request

[0031] Engine torque request control controls engine torque down during power upshifts. Engine torque request con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com