An intelligent water supply pipe quality detection method

A quality inspection method and technology for intelligent water supply, which are applied in pipeline systems, instruments, analysis of solids using sonic/ultrasonic/infrasonic waves, etc., and can solve the problems of complicated pipeline conditions, low detection efficiency, time-consuming and labor-intensive water pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

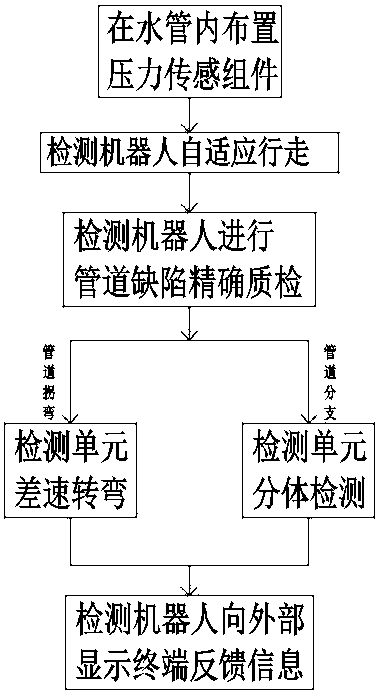

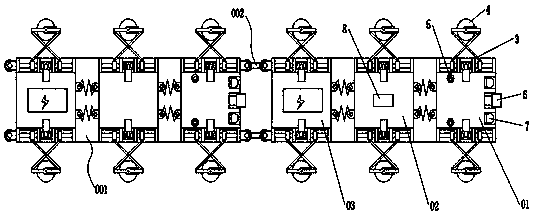

[0037] A kind of intelligent water supply pipe quality detection method of the present embodiment, such as figure 1 and figure 2 As shown, including step A, arranging several groups of pressure sensing components inside the water supply pipeline, it is characterized in that a detection robot is used for pipeline quality detection, and the detection robot includes several detection units 001 sequentially connected by unit springs, so An electromagnetic lock 002 is provided between the end of the unit spring and the detection unit 001; the detection unit 001 includes a first joint 01, a second joint 02, and a third joint 03 which are sequentially connected by connecting springs. The upper and lower sides of the joint 01, the second joint 02, and the third joint 03 are equipped with a telescopic device 3, and the telescopic end of the telescopic device 3 is equipped with a walking wheel 4 that is close to the inner wall of the water pipe. A driving motor for driving the traveli...

Embodiment 2

[0048]This embodiment is further optimized on the basis of Embodiment 1. After the step D, it also includes step E. After the detection robot walks to the pressure change pipe section, the detection robot uses the video monitoring device 6 to video shoot the inside of the pressure change pipe section, and at the same time The detection robot transmits ultrasonic waves to the pipe wall through the ultrasonic detection device 5 and receives reflected ultrasonic waves; the detection robot stops walking when it detects an abnormal reflected ultrasonic waveform through the ultrasonic detection device 5, and then transmits video information, abnormal waveform information, and positioning point information through communication The device 8 sends to the external display terminal.

[0049] During the driving inspection process, the detection robot uses the ultrasonic detection device 5 and the video monitoring device 6 to carry out precise inspection and positioning of defects. The ult...

Embodiment 3

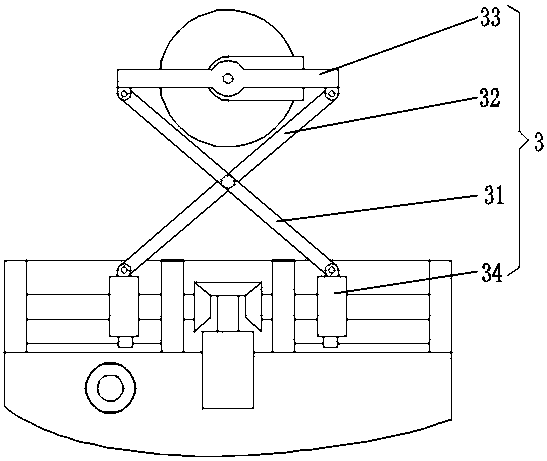

[0052] This embodiment is further optimized on the basis of embodiment 1, such as image 3 As shown, the telescopic device 3 includes a first connecting rod 31, a second connecting rod 32, a loading seat 33, and a moving device 34. The first connecting rod 31 and the second connecting rod 32 form a scissor structure. One end of a connecting rod 31 near the pipe wall and the end of the second connecting rod 32 near the pipe wall are equipped with a loading seat 33, and the end of the first connecting rod 31 away from the pipe wall and the end of the second connecting rod 32 away from the pipe wall are also respectively connected with The two moving ends of the moving device 34 are connected; the moving device 34 is installed on both sides of the installation frame 1 respectively.

[0053] The two moving ends of the moving device 34 can move or be moved toward each other at the same time. When the moving ends move toward each other at the same time, the moving ends respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com