Running control method of cold water unit or heat pump unit

A technology for heat pump units and chillers, used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of low outlet water temperature, affecting the normal operation of the unit, and freezing of pipelines, and achieve the effect of meeting customer needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

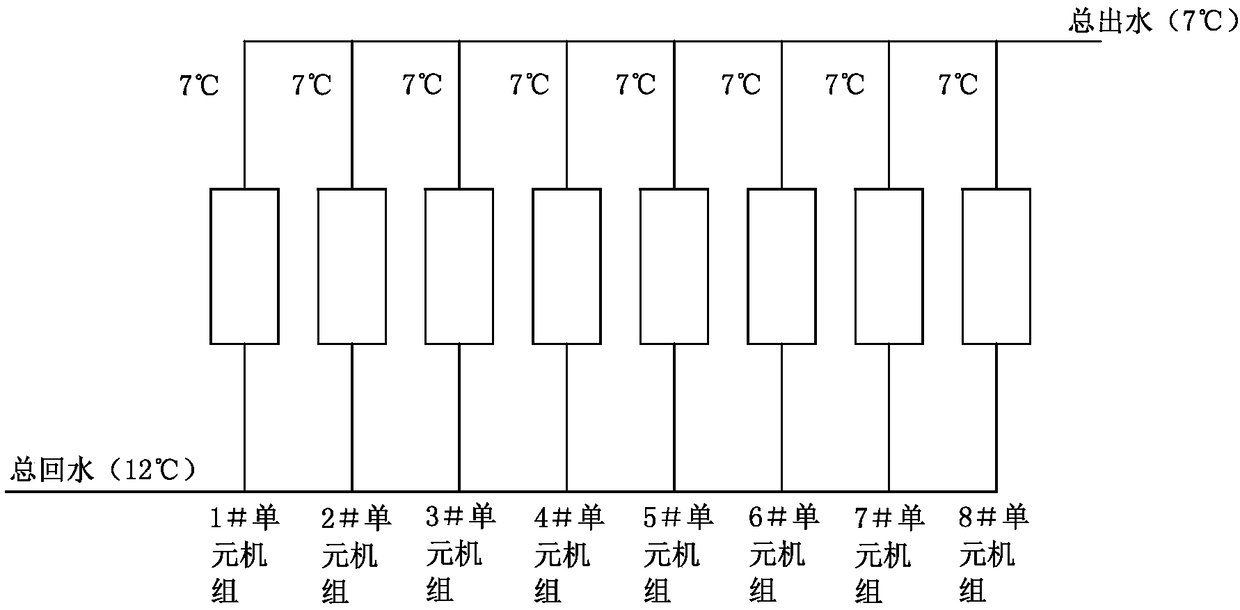

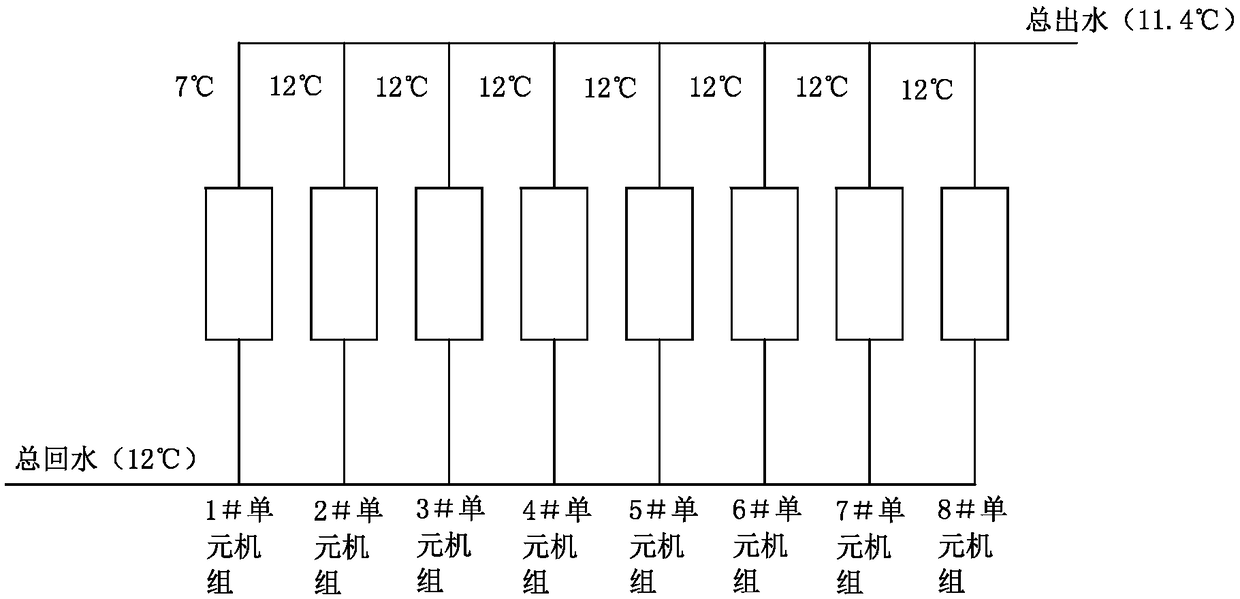

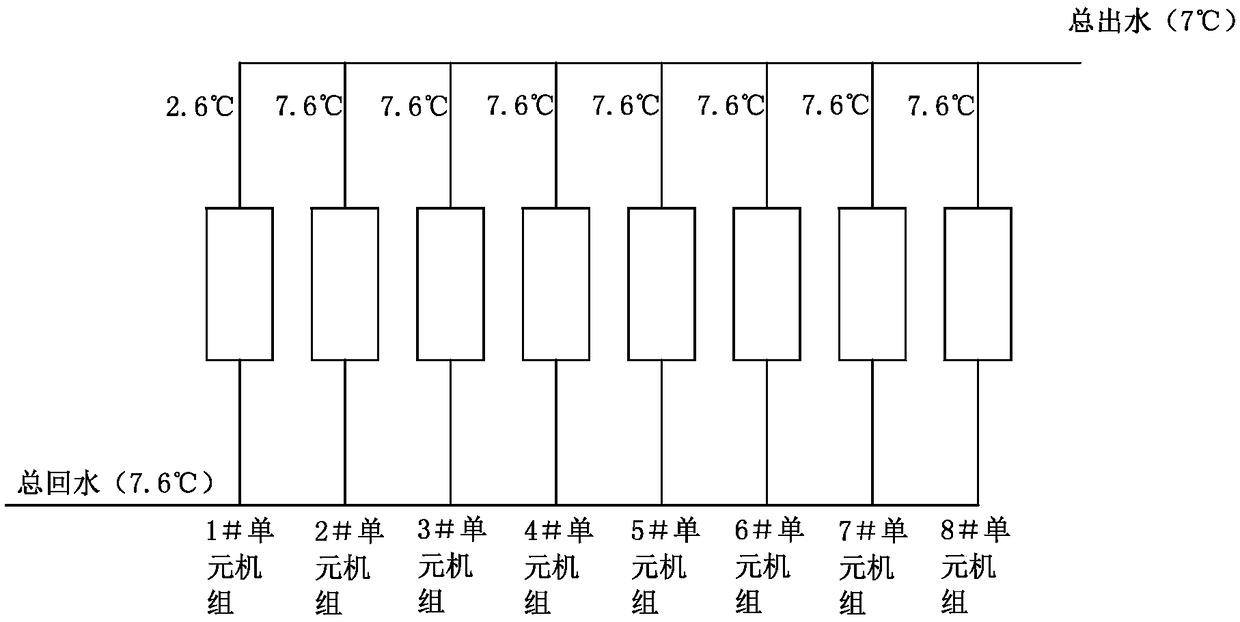

[0048] Each chiller or heat pump unit includes 8 unit units, and the 8 unit units operate in parallel, each unit unit includes 4 compressors, and the running time of the 8 unit units is T, T=2; the 8 unit units are respectively They are 1# unit unit, 2# unit unit, 3# unit unit, 4# unit unit, 5# unit unit, 6# unit unit, 7# unit unit and 8# unit unit.

[0049] The operation control method of the present invention is used to alternately load and unload the compressors in the eight unit units one by one to achieve balanced and decentralized operation. The operation control method includes the following steps:

[0050] S1. Calculate the least common multiple of 2, 3, and 4 that can be selected by compressors as the total load of the unit unit; calculate the ratio of the total load of the unit unit to the number of compressors in the unit unit, and calculate it as the load of each compressor; calculate the unit The product of the load of each compressor in the unit and the operating...

Embodiment 2

[0089] The concept of the second embodiment is basically the same as that of the first embodiment. The only difference is that the number of unit units, the number of compressors in the unit unit and the setting of the unit running time are different. The following will only describe this embodiment for the differences.

[0090] The chiller unit or heat pump unit includes 4 unit units, the 4 unit units are 1# unit unit, 2# unit unit, 3# unit unit, 4# unit unit; 1# unit unit includes 3 compressors, each compressor Machine load = 4; 2# unit unit includes 2 compressors, each compressor unit load = 6; 3# unit unit and 4# unit unit both include 4 compressors, each compressor unit load = 3, and 1 The running time of #unit unit is T=2, the running time of 2# unit unit is T+1=3, the running time of 3# unit unit is T+3=5, the running time of 4# unit unit is T+2 = 4; The sequence of 4 unit units is set in advance as 1# unit unit, 2# unit unit, 3# unit unit and 4# unit unit. In order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com