A sample preparation device, method and test method for geotechnical tensile test

A technology of tensile test and stretching section, which is applied in the field of sample preparation device for geotechnical tensile test, which can solve the problem of extrusion deformation at the joint between sample and fixture, easy slippage between sample and fixture, and reduced reliability of test results To achieve the effect of improving friction, convenient and quick sample preparation, accurate tensile strength and stress-strain curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

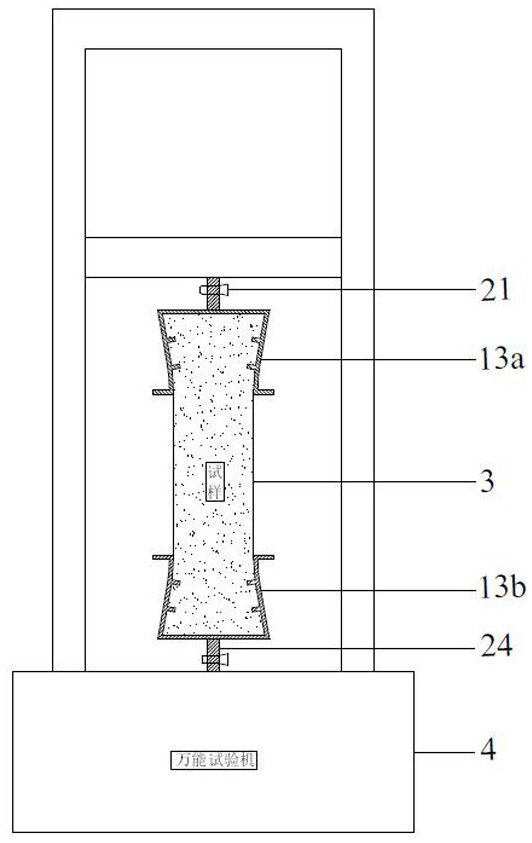

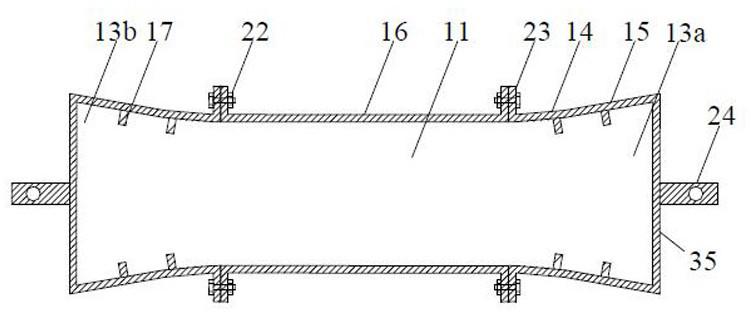

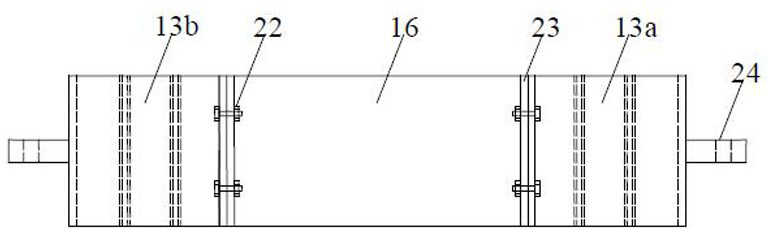

[0043] Such as Figure 2~Figure 6 As shown, the sample preparation device for geotechnical tensile test includes: sample preparation mold 11, sample preparation base plate 12 and compaction module 31:

[0044] Sample preparation mold such as figure 2 , image 3 As shown, the circular arc transition section 14 of the first drawing fixture 13a is connected longitudinally to the middle drawing section 16 by bolts 22 at the connecting flange 23 of the side wall, forming a sample preparation mold 11 with a cavity structure;

[0045] The first tensioning fixture 13 a includes: an end limiting plate 35 and limiting arms respectively arranged at two ends of the end limiting plate, and the limiting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com