Heat dissipation device and a heat dissipation method of a hard disk

A technology of heat dissipation device and hard disk, which is applied in the direction of instruments, electrical digital data processing, digital data processing parts, etc. The effect of increasing the heat dissipation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

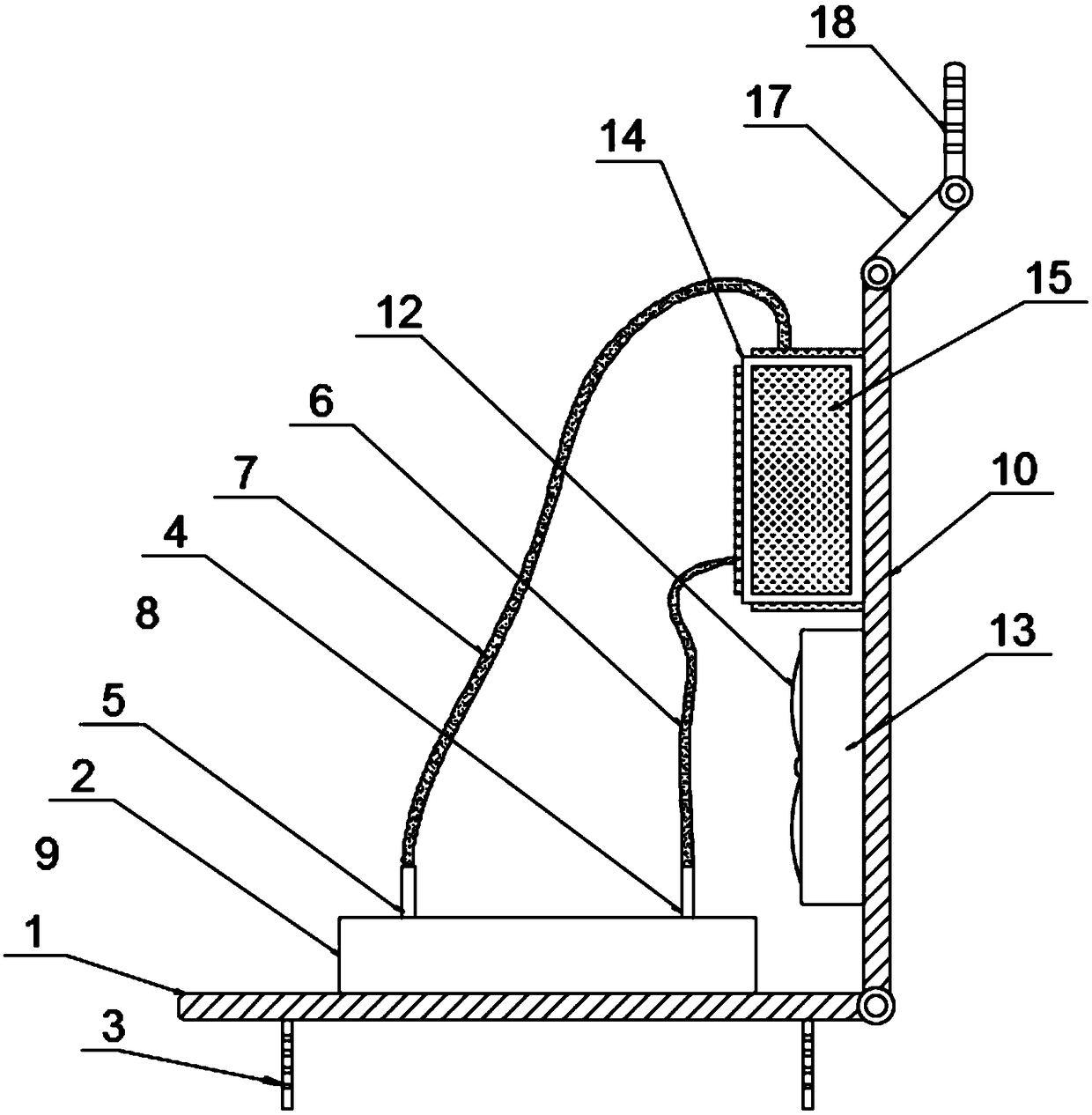

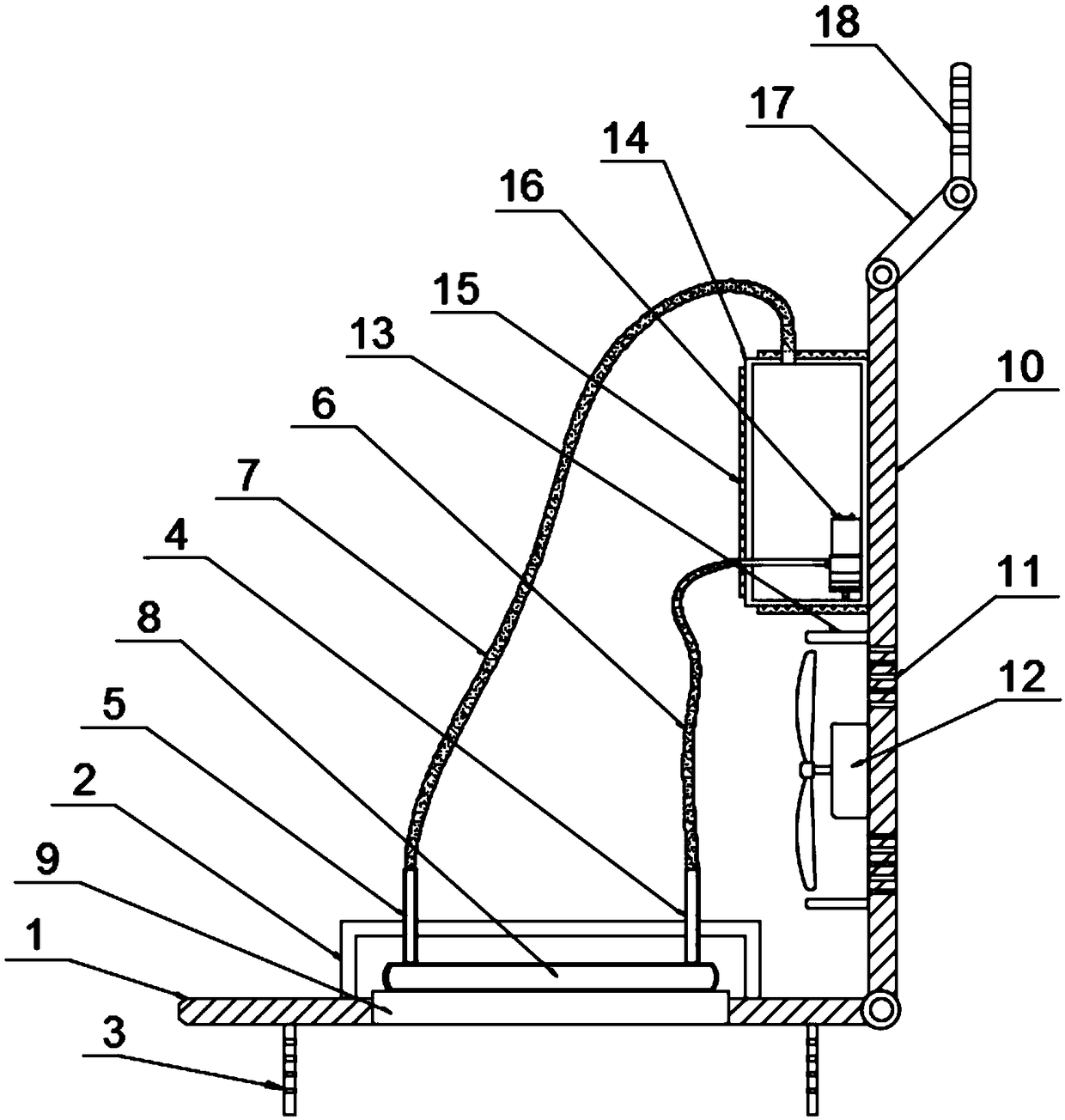

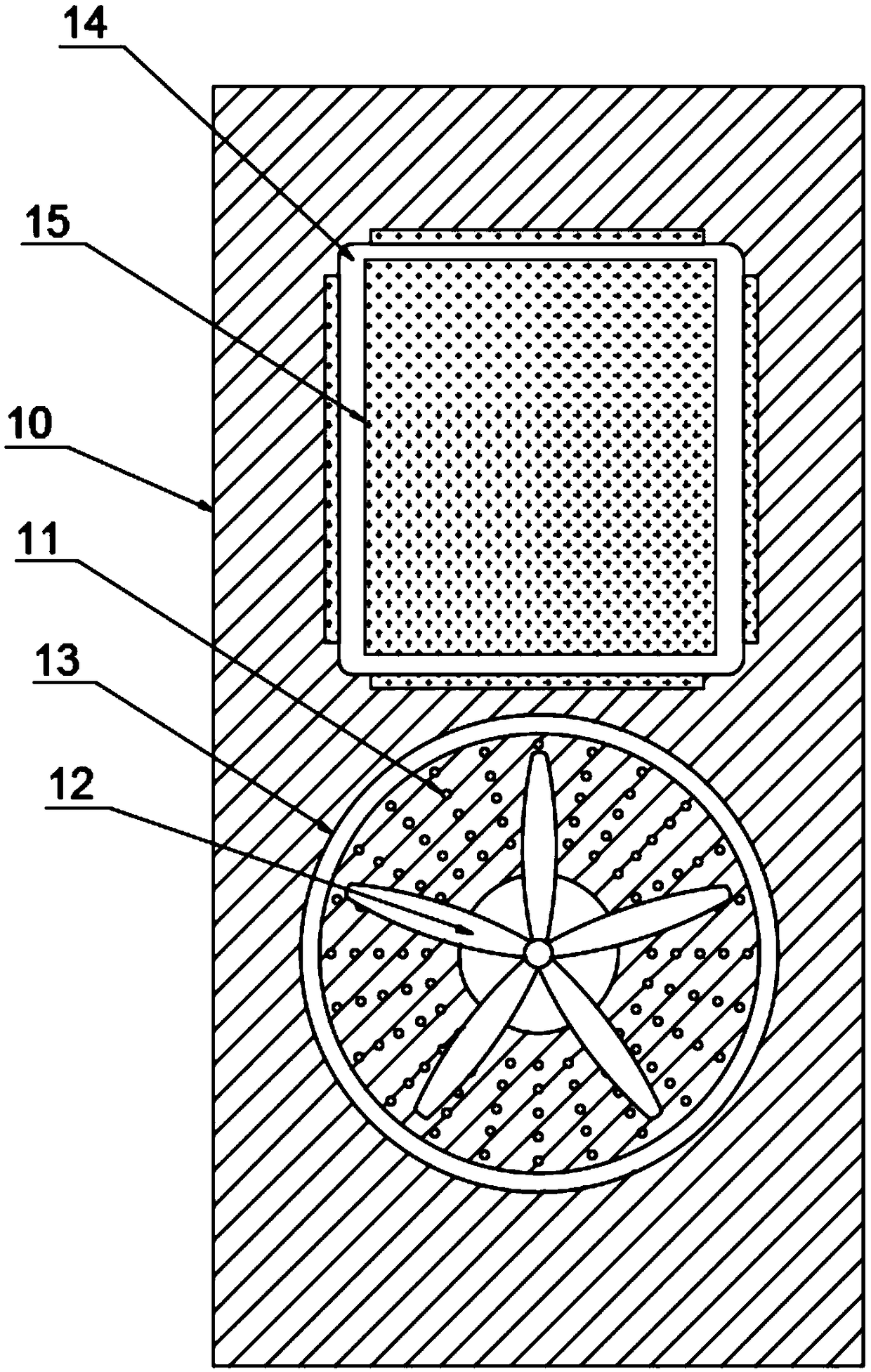

[0028] The present invention provides such Figure 1-3 The hard disk cooling device shown includes a base plate 1, a heat absorption box 2 is provided on the top of the base plate 1 and a first mounting plate 3 is provided at the bottom, and a water inlet pipe 4 and an outlet pipe are provided on the top of the heat absorption box 2. 5. The top of the water inlet pipe 4 is provided with a first connecting hose 6, the top of the outlet pipe 5 is provided with a second connecting hose 7, the inner cavity of the heat-absorbing box 2 is provided with a cooling water pipe 8, and the cooling water pipe 8. A red copper heat conduction plate 9 is provided at the bottom, and a vertical plate 10 is provided on one side of the bottom plate 1. A plurality of cooling holes 11 are provided on the vertical plate 10. A cooling fan 12 is provided on one side of the vertical plate 10. The outside of cooling fan 12 is provided with circular partition 13, and the top of described circular partiti...

Embodiment 2

[0037] A hard disk cooling method, including the hard disk cooling device, also includes the following steps:

[0038] S1: align the first mounting plate 3 at the bottom of the bottom plate 1 with the edges on both sides of the hard disk rack;

[0039] S2: Use screws to pass through the threaded holes on the first mounting plate 3 to fix the bottom plate 1 on the hard disk rack. vertical angle of

[0040] S3: adjusting the angle of the second mounting plate 18 on the top of the riser 10 by using the connecting rod 17 and the hinge shaft;

[0041] S4: then use screws to pass through the threaded holes on the second mounting plate 18 to fix the riser 10 inside the computer case;

[0042] S5: When the hard disk is working, the copper heat conduction plate 9 attached to the top of the hard disk absorbs the heat generated by the hard disk, and the cooling water pipe 8 attached to the top of the copper heat conduction plate 9 absorbs the heat on the copper heat conduction plate 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com