Storage liquid shaking control method of floating-type oil and gas production storage and discharging device

A kind of oil and gas, floating technology, applied in the direction of transportation and packaging, used for bulk cargo, equipment to reduce ship movement, etc., can solve the problems that affect the safety of oil and gas transportation process, increase transportation cost, sacrifice transportation efficiency, etc., to increase progress and benefits, reducing gasification loss, and improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with specific embodiments.

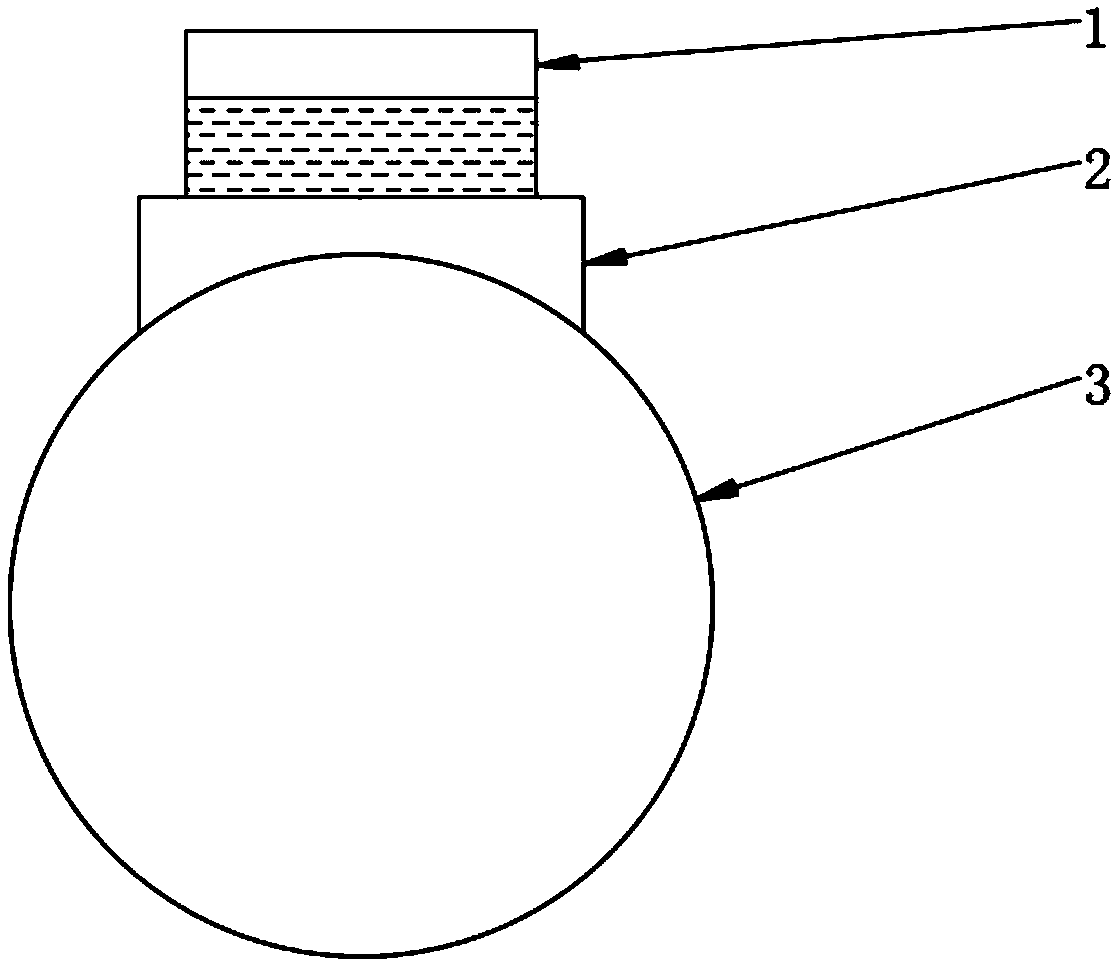

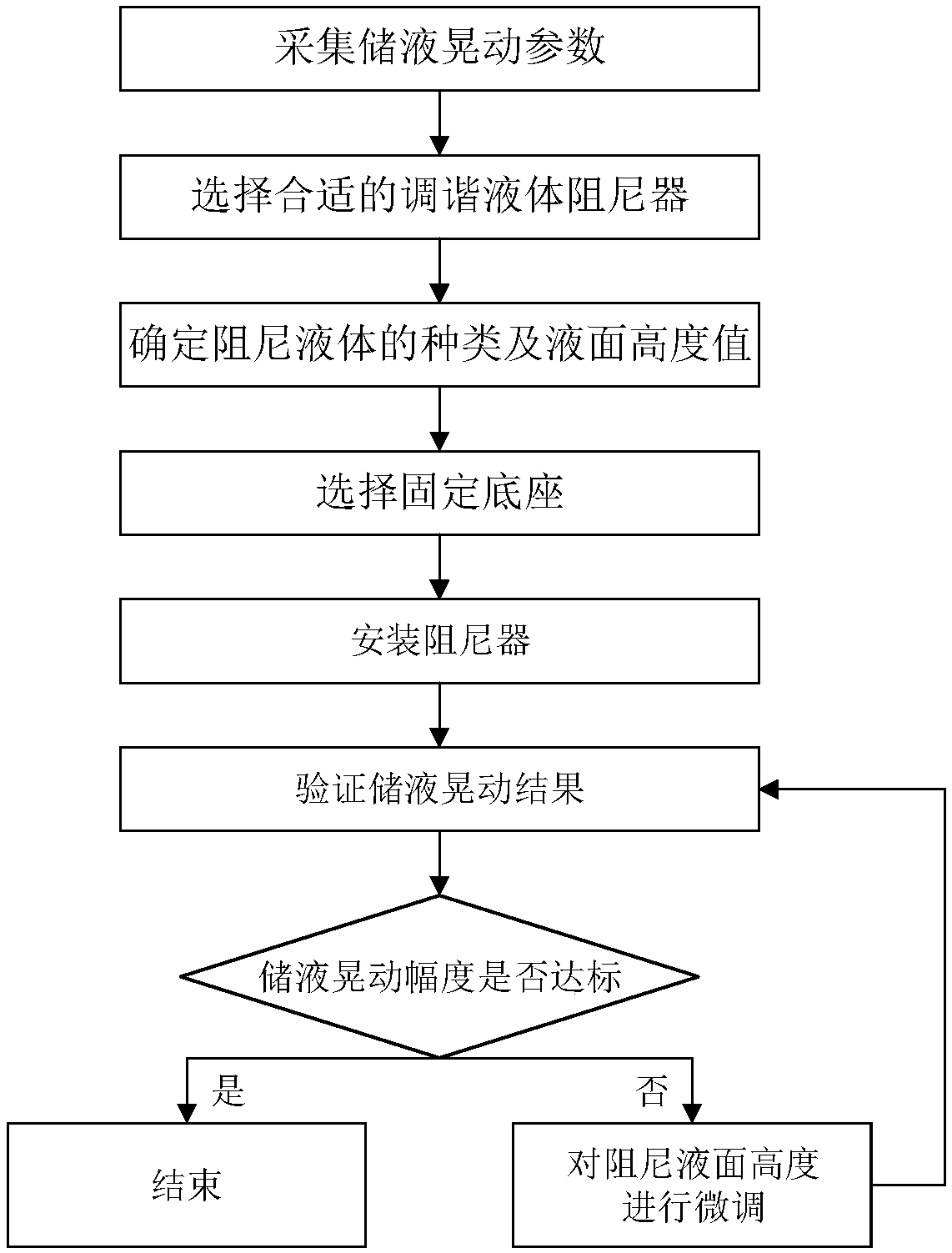

[0017] Such as figure 1 , 2 The liquid storage sloshing control method of the floating oil and gas production, storage and unloading device shown in the present invention includes the following steps:

[0018] Step 1. Calculating the first-order vibration frequency of liquid storage sloshing in the floating oil and gas production, storage and unloading device. The specific steps are: arrange acceleration sensors on the floating oil and gas production, storage and The vibration acceleration data collected during the process is analyzed to obtain the first-order vibration frequency of the storage liquid sloshing of the floating oil and gas production, storage and unloading device. The sampling time of the vibration acceleration data is usually the vibration acceleration during 1 to 2 hours of transportation at a constant speed;

[0019] Step 2. Determine the basic paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com