Dense phase positive pressure pneumatic conveying system

A Pneumatic Conveying System, Dense Phase Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

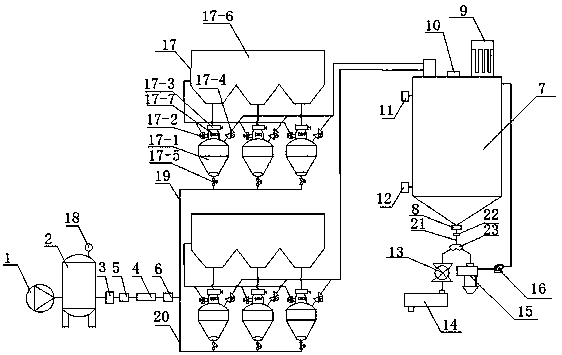

[0010] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

[0011] Such as figure 1 As shown, a dense phase positive pressure pneumatic conveying system includes an air compressor 1, an air storage tank 2, an oil-water separator 3, an air dryer 4, a first filter 5, a second filter 6, and an ash storehouse 7 , flexible joint 8, bag filter 9, pressure relief valve 10, high-level material level gauge 11, low-level material level gauge 12, air-lock feeder 13, humidifying mixer 14, dry discharge head 15, fan 16 and At least two sets of conveying devices 17, the air compressor 1 is a bipolar permanent magnet variable frequency air compressor, one end of the air compressor 1 is connected with an air storage tank 2, an oil-water separator 3, a first filter 5, Air dryer 4 and second filter 6, said air storage tank 2 is provided with a pressure gauge 18, said second filter 6 is provided with a first branch 19 and a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com