Oiling equipment for chemical fiber silk production

A technology of chemical fiber yarn and equipment, applied in the field of oiling equipment for chemical fiber yarn production, can solve the problems of poor chemical fiber oil leakage effect, easy wear of roller shaft, poor oiling effect of chemical fiber yarn, etc., and achieves safe and convenient use. , The effect of reducing the contact area and reducing the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

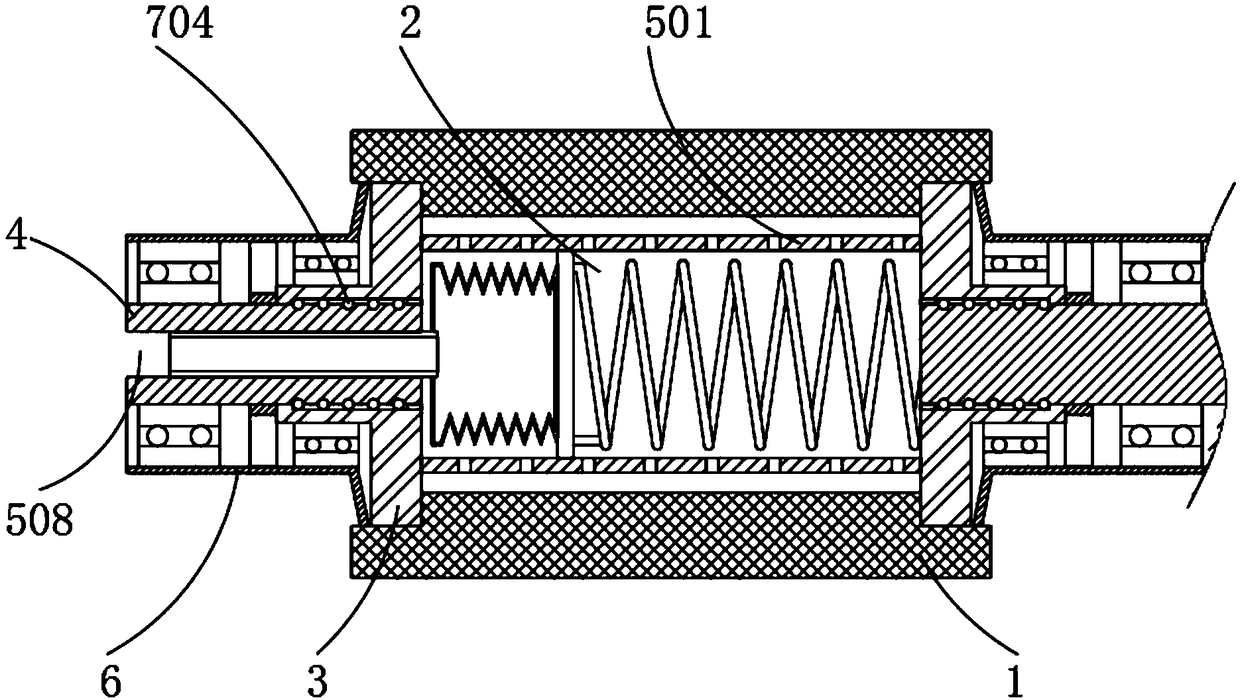

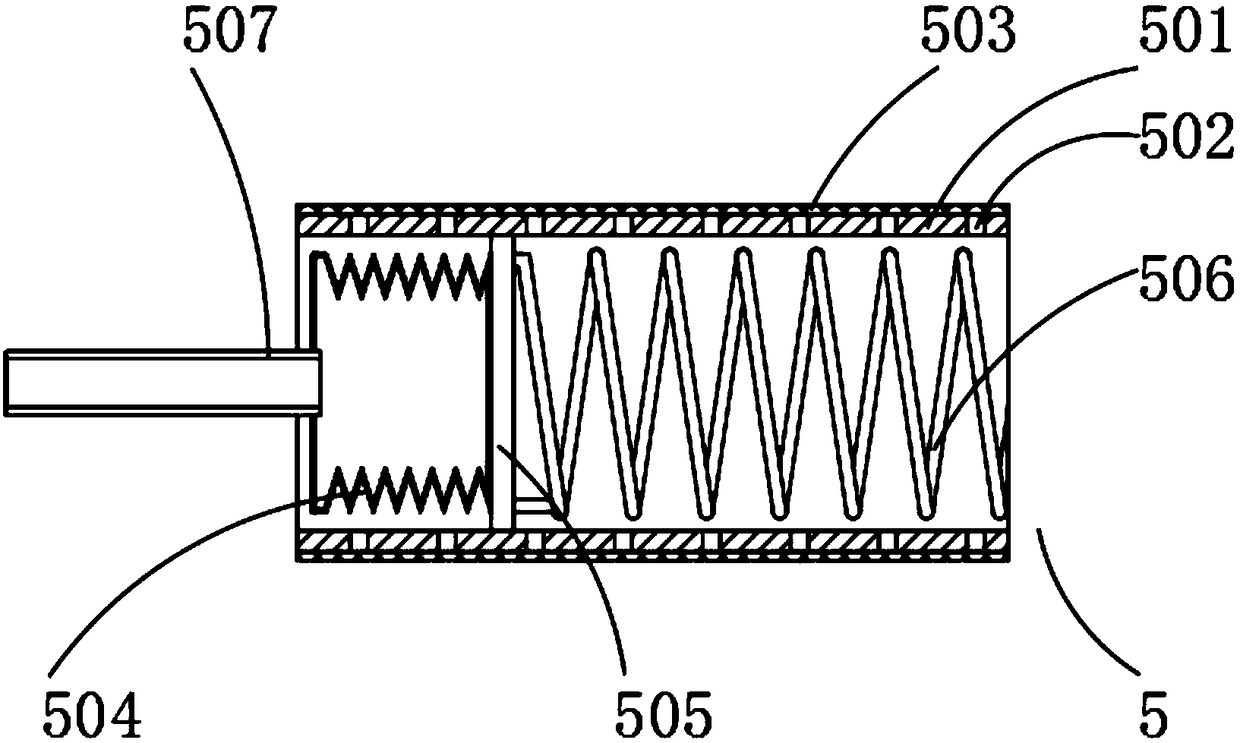

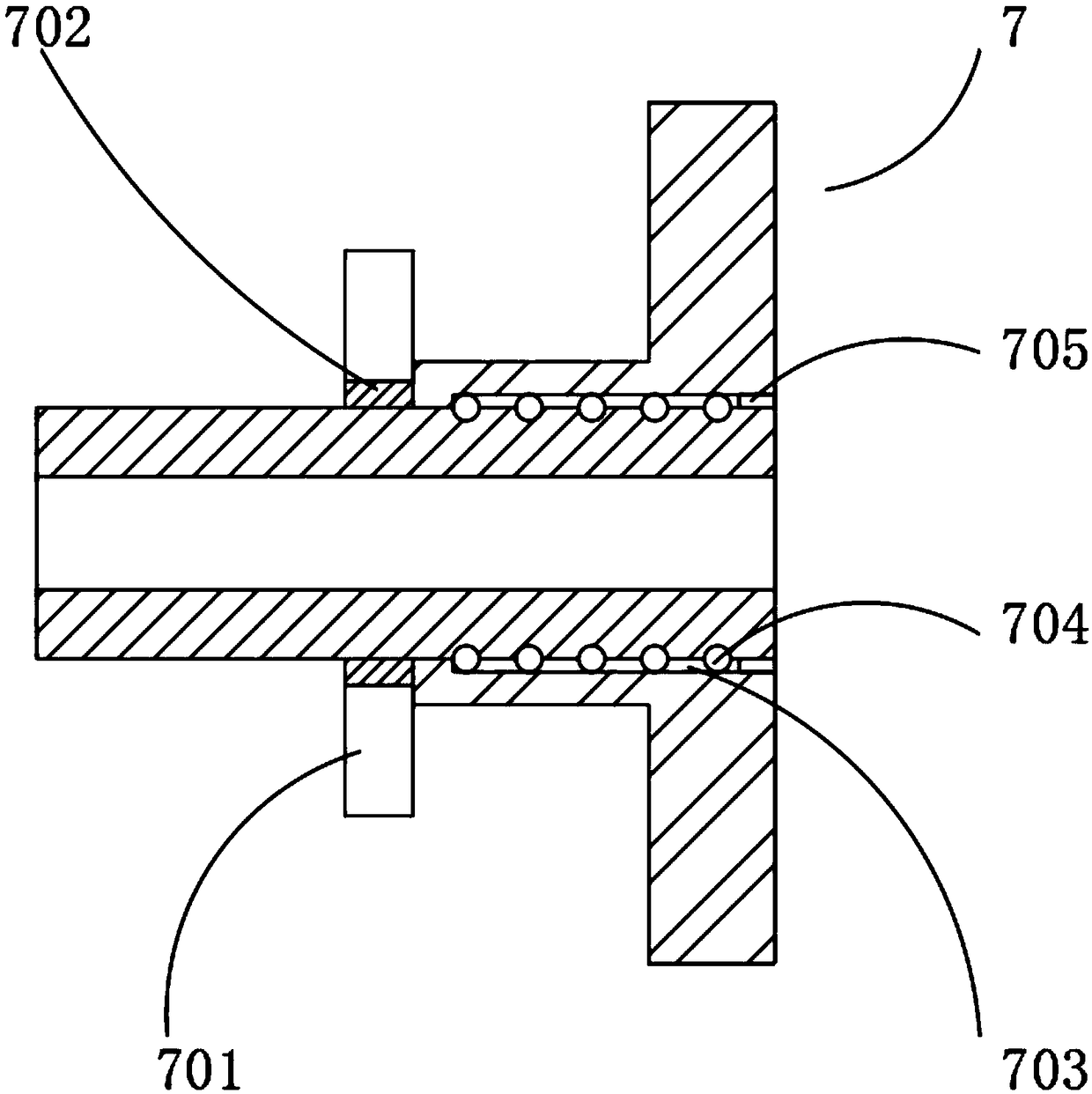

[0023] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a kind of oiling equipment for chemical fiber yarn production, comprising an oil roller 1, an oil storage chamber 2 is opened inside the oil roller 1, and sealing end caps 3 are installed at both ends of the oil roller 1, A connecting shaft 4 runs through the middle of the sealing end cap 3, and an adjustment assembly 5 is installed between the two sealing end caps 3, the adjustment assembly 5 includes an oil seepage cover 501, an oil seepage hole 502, a filter screen 503, an air bag 504, a rubber plate 505, The spring 506, the inflation tube 507 and the installation hole 508, and the oil seepage cover 501 are installed inside the oil storage chamber 2. In order to facilitate the lubrication of the chemical fiber oil through the oil seepage cover 501 and the oil roller 1, the inside of the oil storage chamber 2 is filled with chemical fiber oil. The side of the oil seepage cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com