Injecting pipe, manufacturing method and gas stove burner therefore

A technology for injection tubes and stoves, which is applied in the field of injection tubes, can solve the problems of affecting the combustion rate, reducing the gas flow rate, and heating of the injection tube, so as to ensure the gas ejection speed, improve high temperature resistance, and improve firmness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

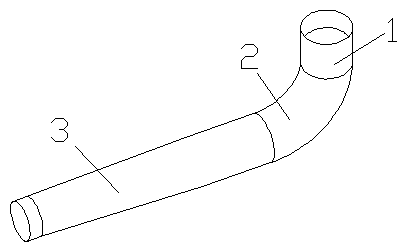

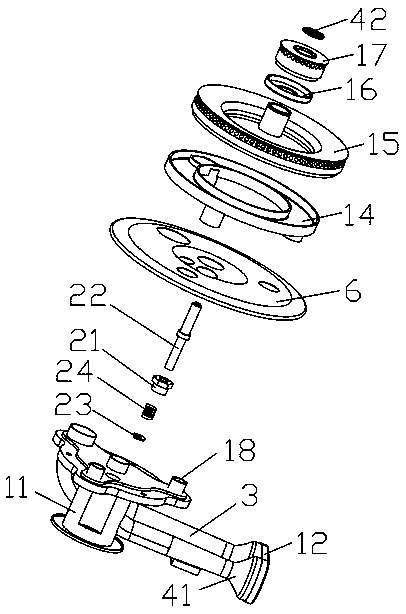

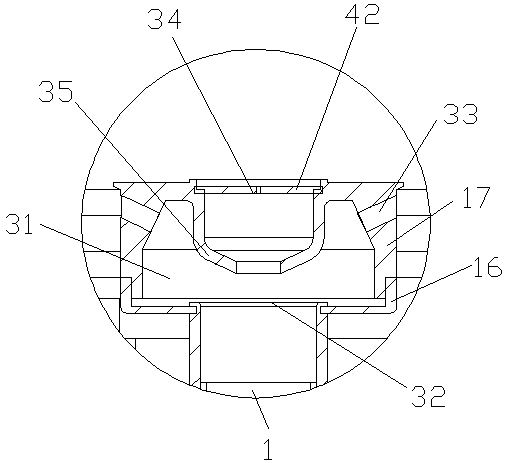

[0038] Such as figure 1 Shown is a kind of injection tube, comprising a first stainless steel hollow injection tube body 1, a stainless steel hollow connection injection tube body 2 and a second stainless steel hollow injection tube body 3, one end of the stainless steel hollow connection injection tube body 2 is connected to The first stainless steel hollow injection tube body 1 is connected, the other end of the stainless steel hollow connection injection tube body 2 is connected with the second stainless steel hollow injection tube body 3, and the first stainless steel hollow injection tube body 1, the stainless steel hollow injection tube body Connecting the ejector body 2 and the second stainless steel hollow ejector body 3 are integrally manufactured without solder joints; the ejector tube of the second stainless steel hollow ejector body 3 that is connected to one end of the stainless steel hollow ejector body 2 The diameter is larger than the diameter of the injection ...

Embodiment 2

[0075] The difference between Example 2 and Example 1 lies in the composition ratio of the raw materials of the high-temperature-resistant heat-insulating coating, which is made of the following raw materials in mass percentage:

[0076] Epoxy modified silicone resin 70%;

[0077] Hollow glass microspheres 12%;

[0078] Low temperature molten glass powder 8%;

[0079] Perlite 7%;

[0080] Dispersant 1%;

[0081] Defoamer 2%.

Embodiment 3

[0083] The difference between Example 3 and Example 1 lies in the composition ratio of the raw materials of the high-temperature-resistant heat-insulating coating, which is made of the following raw materials in mass percentage:

[0084] Epoxy modified silicone resin 66%;

[0085] Hollow glass microspheres 13%;

[0086] Low temperature molten glass powder 9%;

[0087] Perlite 8%;

[0088] Dispersant 2%;

[0089] Defoamer 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com