Testing device for identifying sealing performance of nonmetal sealing member and method thereof

A test device, a technology of sealing performance, applied in liquid/vacuum measurement for liquid tightness, by measuring the acceleration and deceleration rate of the fluid, by detecting the appearance of the fluid at the leak point, etc. Test software is not very ideal, auditing and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention will be further described below in conjunction with the drawings and embodiments.

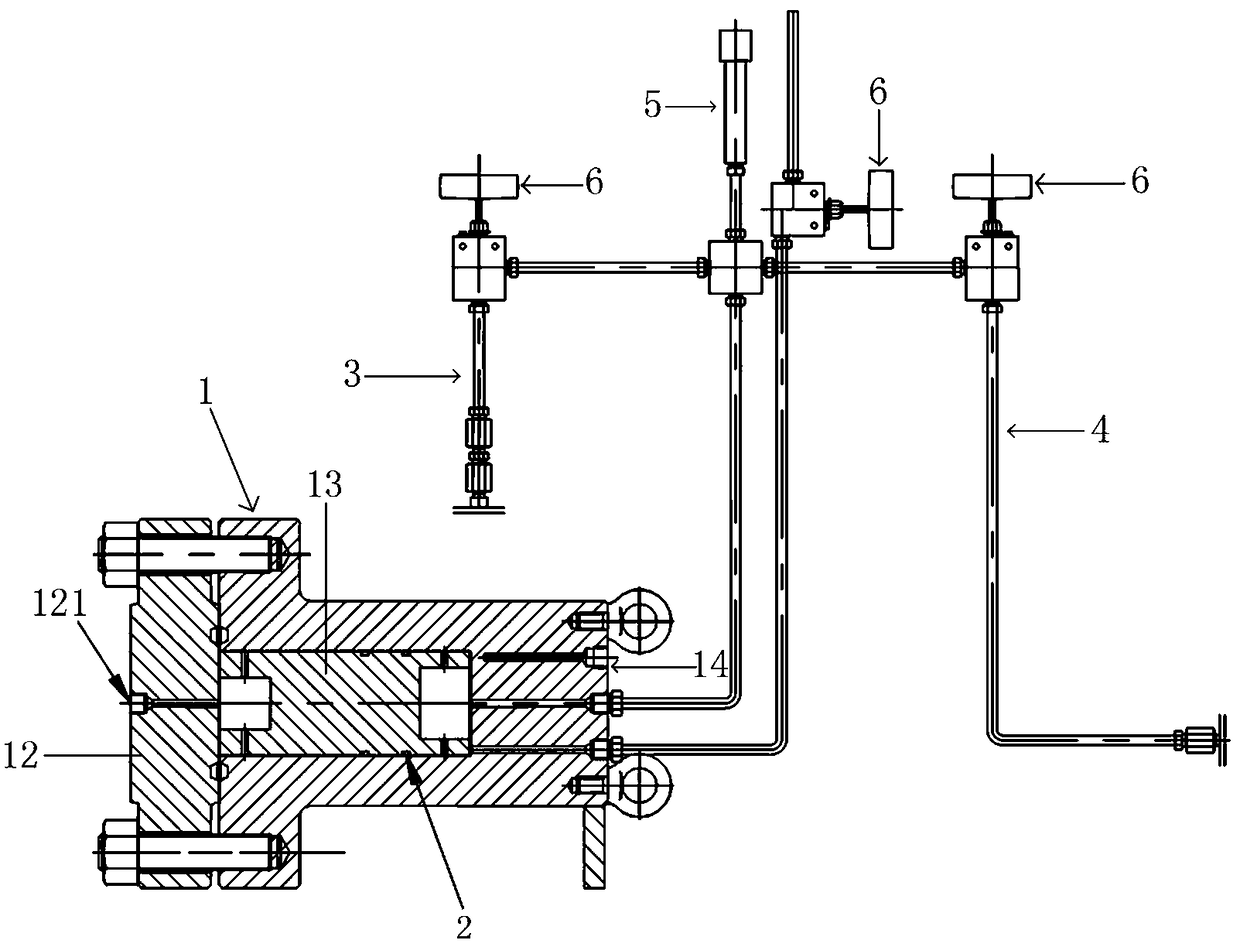

[0043] Such as figure 1 As shown, the present invention provides a kind of test device for non-metallic seal sealing performance appraisal, and this test device is mainly aimed at Qualification test of PR2 level sealing performance of type seal ring (S seal) or similar products. The test device comprises: a device body 1, which has a cavity inside, and the cavity is opened at the bottom of the device body 1; the bottom of the device body 1 is provided with a bottom cover 12 closely connected with the device body 1; There is a filler 13 with a gap in the inner wall of the device body 1, the gap between the inner wall of the device body 1 and the side wall of the filler 13 is provided with a non-metallic seal 2 to be detected; the top of the device body 1 is provided with a seal that communicates with the cavity. The liquid injection port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com