Detection method of pre-set fabric and fabric pre-set processing method

A technology of processing method and detection method, applied in the field of fabric pre-forming processing and pre-forming fabric detection, can solve the problems of low efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

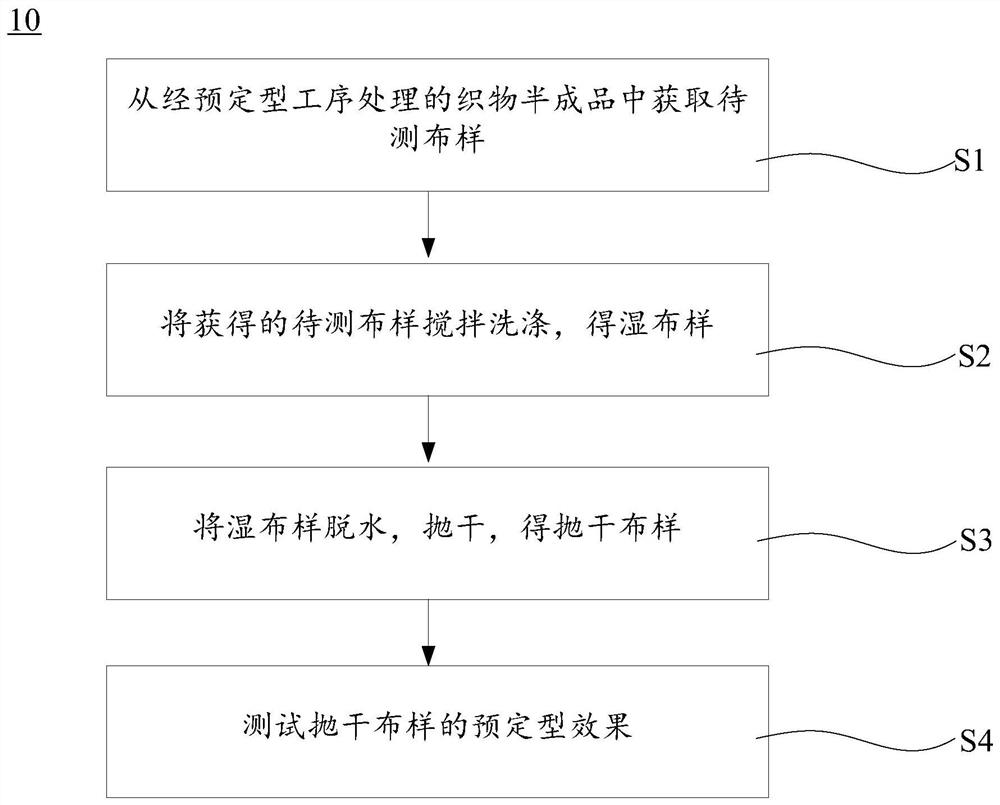

[0044] Please combine figure 1 , the present embodiment provides a detection method 10 of pre-shaped fabrics, including the following steps:

[0045] Step 1: Obtain a cloth sample to be tested from the semi-finished fabric product processed by the presetting process. Specifically, a 0.5-yard full-width sample can be cut from the semi-finished fabric that has been processed in the pre-setting process, and a 30cm×30cm square detection area (corresponding to the detection The initial side length of the region).

[0046] Step 2: Place the cloth sample to be tested obtained in step 1 under the condition of water temperature of 50±2°C, stirring and washing, the stirring speed is 150±2r / min, and the stirring time is 10±1min, to obtain a wet cloth sample.

[0047]Step 3, put the wet cloth sample obtained in step 3 in a dehydrator for dehydration, the speed of dehydration is 360r / min, and dehydrate for 3±1min; put the dehydrated cloth sample in a throwing dryer, and throw it under th...

Embodiment approach 2

[0056] The present embodiment provides a fabric presetting processing method, comprising the following steps:

[0057] S1. Presetting the initial stretch rate, initial temperature and initial machine speed according to the raw material cloth to be pre-shaped, and performing a pre-setting process on the raw material cloth to be pre-shaped.

[0058] According to the cloth type or yarn type of the raw material cloth to be pre-shaped, preferably, the initial stretch rate in the pre-setting process is preset according to the standard stretch rate of the width of the door as in Table 1, so that it can be quickly obtained. The production process obtains the predetermined process parameters of the standard fabric.

[0059] Table 1

[0060]

[0061] Remarks: "——" means that the corresponding cloth type does not need standard grammage as the selection condition.

[0062] The setting of the standard stretch rate of the door width is not only related to the tightness of the warp and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com