Vertical uninterrupted all-directional automatic roller coating device

An all-round, roller coating technology, which is applied to the surface coating liquid device, mixer with rotating stirring device, coating, etc., can solve the problems of time-consuming and labor-intensive, and achieve convenient operation and automatic continuous roll coating Simple effect of work and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

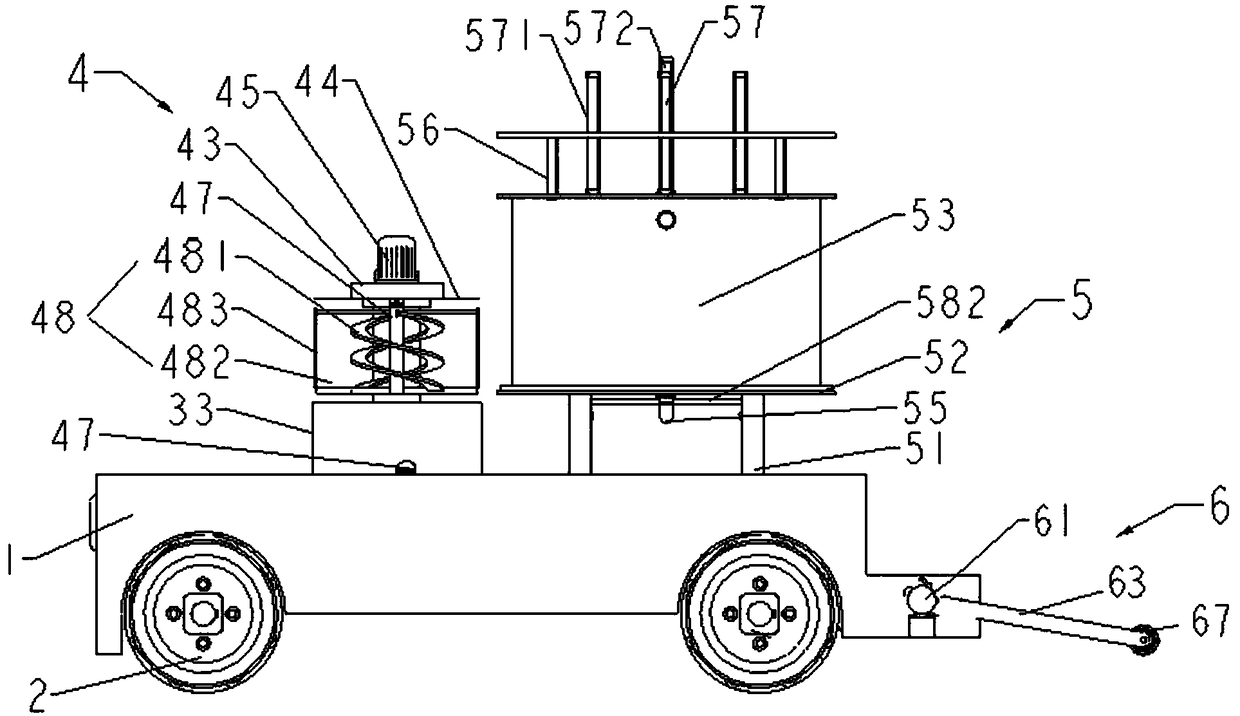

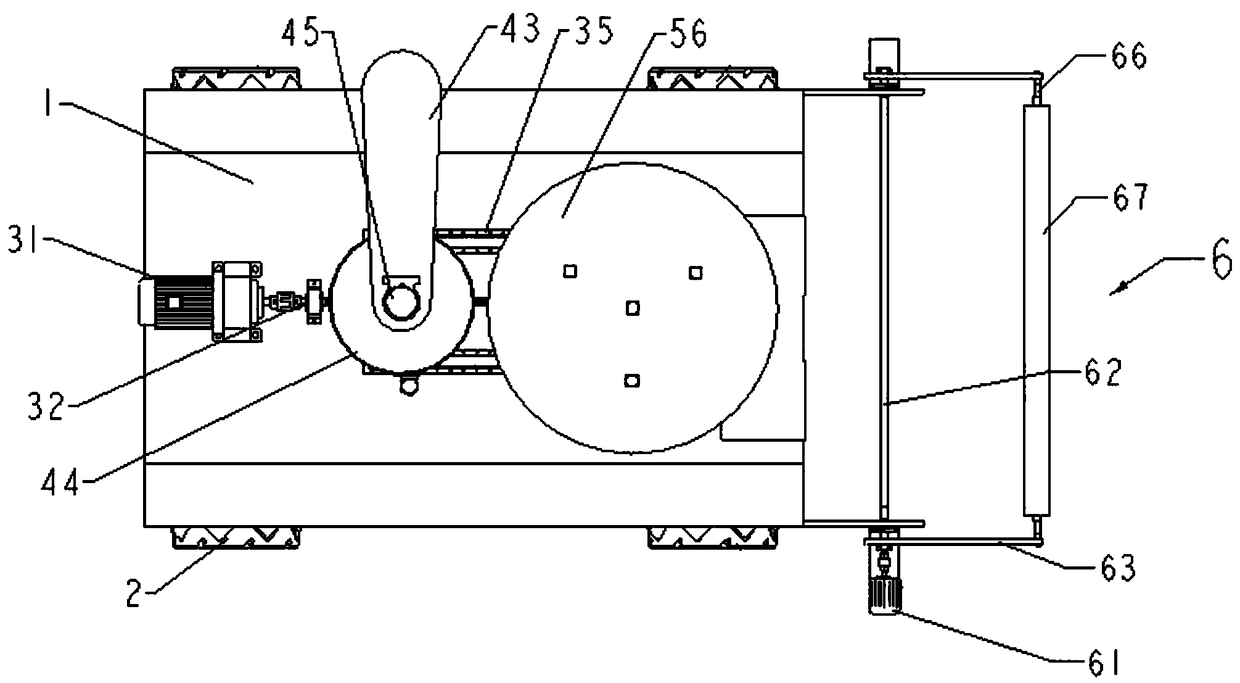

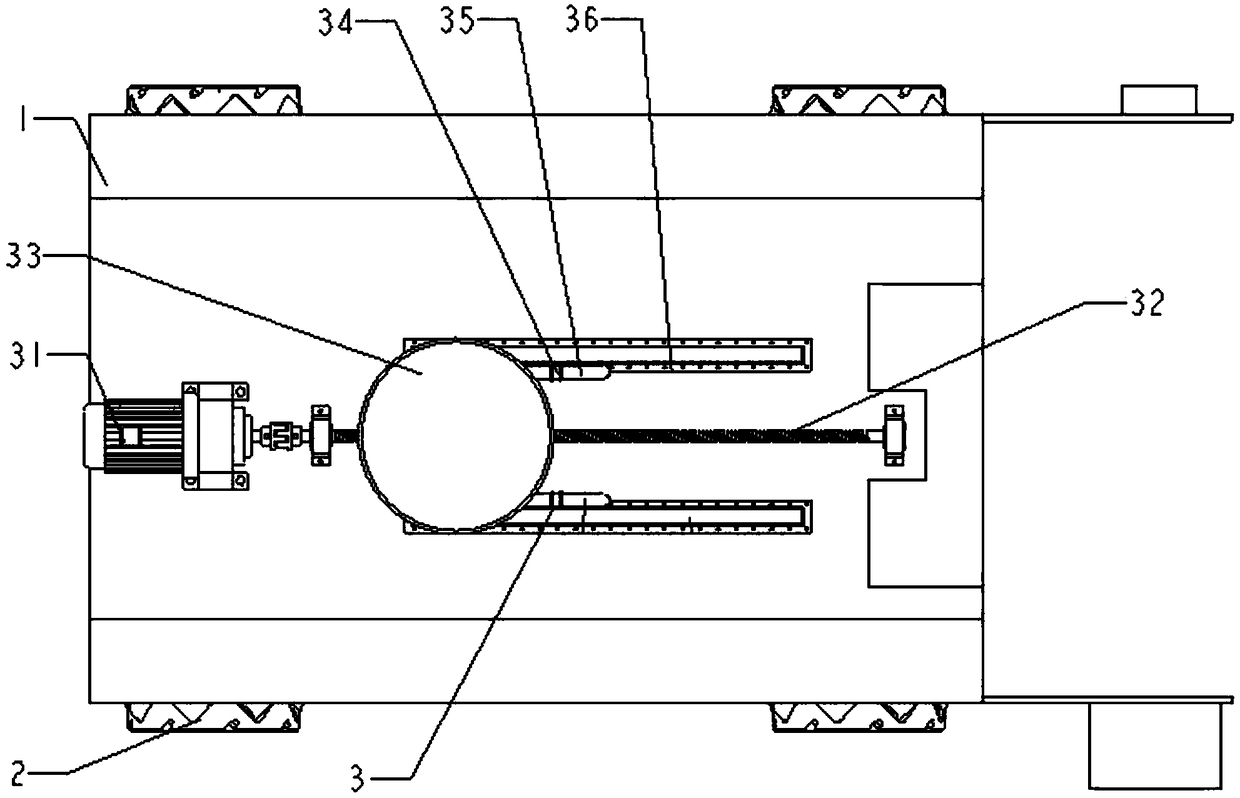

[0022] In the following, the vertical uninterrupted omnidirectional automatic roller coating device of the present invention will be further described with reference to the accompanying drawings.

[0023] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8, a vertical uninterrupted omnidirectional automatic roller coating device of the present invention includes: U-shaped traveling platform frame 1, omnidirectional wheel 2, material transport device 3, material Stirring device 4, feeding-discharging dual function device 5, roller coating device 6; the U-shaped traveling platform frame 1 has four omnidirectional wheels 2 installed symmetrically at the bottom; the motor I31 in the material transport device 3 passes through bolts It is fixedly installed at the rear end of the U-shaped traveling platform frame 1; the hydraulic cylinder support seat 41 of the material mixing device 4 is fixedly installed on one side of the U-shaped traveling platform frame 1 by bolts; the feeding-unloading Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com