Formation machine for surface pattern of automobile sealing strip

A technology for automotive sealing strips and forming machines, which is applied in the field of auto parts processing, can solve the problems of single pattern forming function, inability to process intermittent patterns, and lack of sealing strips, etc., so as to avoid inconvenience of movement, good forming effect and high forming efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

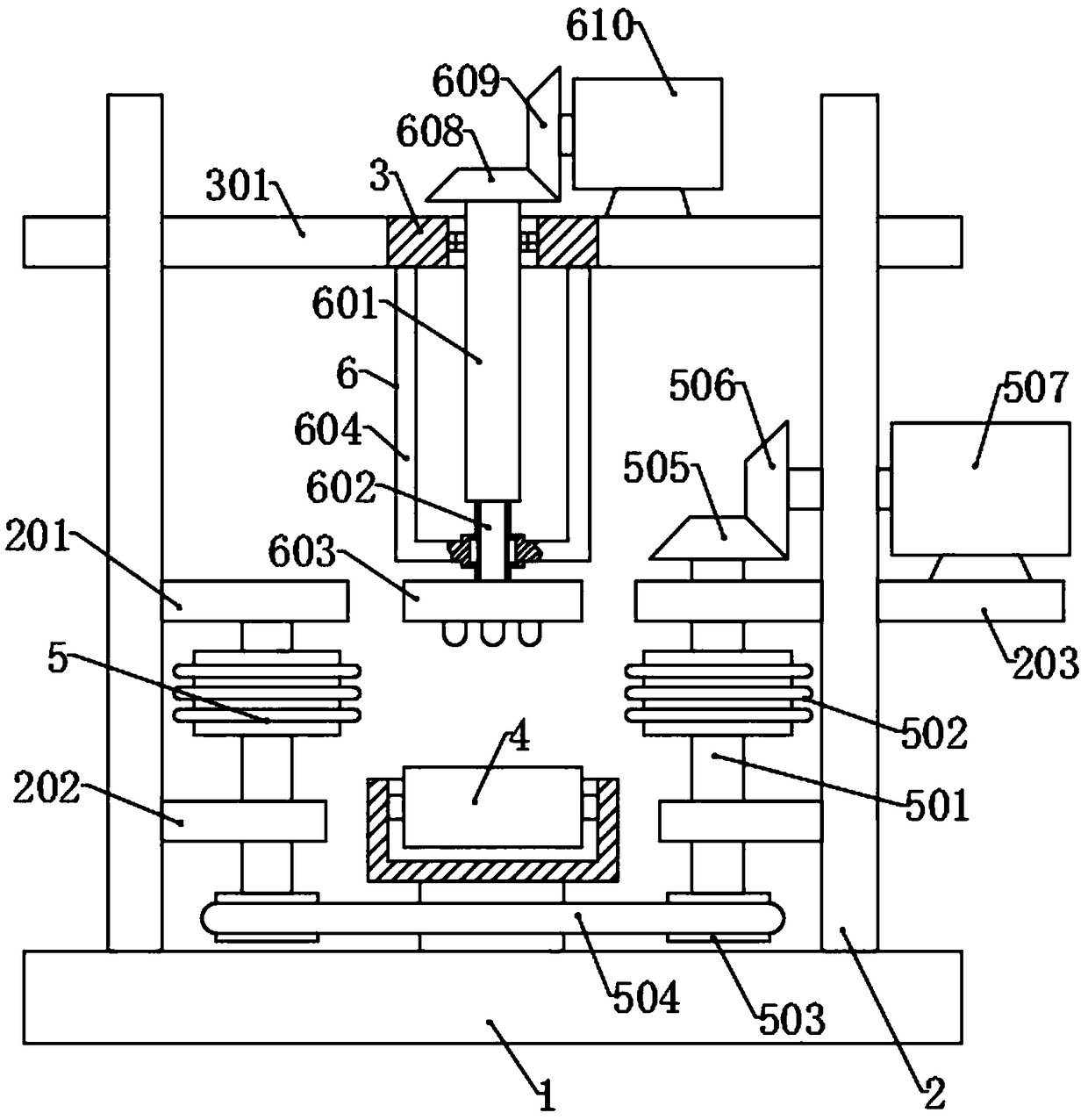

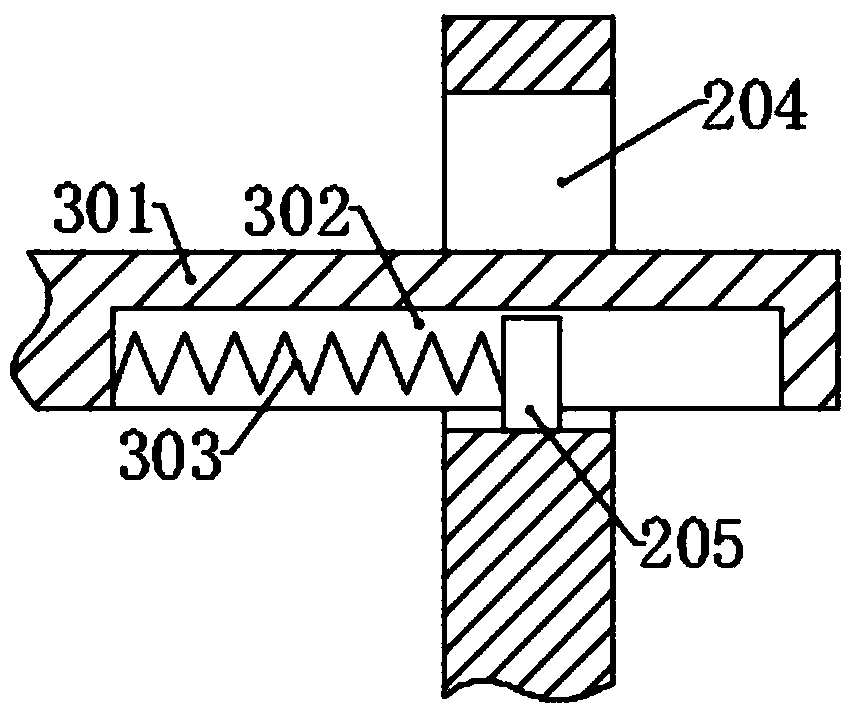

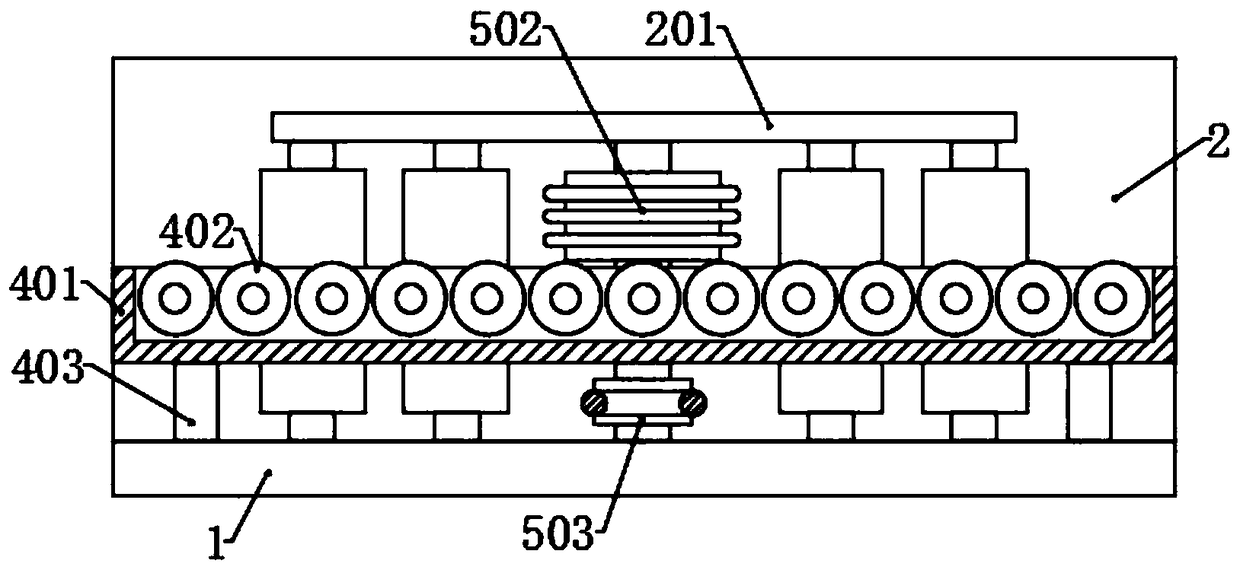

[0034] Please refer to the accompanying drawings, the present invention provides a technical solution: a surface pattern forming machine for automobile weather strips, including a base 1, a lateral embossing mechanism 5 and a vertical embossing mechanism 6, characterized in that the base 1 Vertical side plates 2 are symmetrically fixed on both sides of the top surface, and a top plate 207 is arranged between the tops of the side plates 2. The lateral embossing mechanism 5 includes two sets of embossing components, which are respectively arranged inside the two side plates 2. The bottom of the side and the support assembly 4 are arranged between the two groups of embossing assemblies. The vertical embossing mechanism 6 is arranged on the top plate 207 and above the support assembly 4 .

[0035] The top surface of the base plate is provided with an adjustment groove 101, and two adjustment screw rods 105 are rotationally connected in the adjustment groove 101, and the direction o...

Embodiment 2

[0042] A surface pattern molding machine for automobile weather strips, comprising a base 1, a lateral embossing mechanism 5 and a vertical embossing mechanism 6, characterized in that vertical side plates 2 are symmetrically fixed on both sides of the top surface of the base 1, A top plate 207 is provided between the tops of the side plates 2, and the lateral embossing mechanism 5 includes two groups of embossing assemblies, which are respectively arranged at the bottom of the inner sides of the two side plates 2, and between the two groups of embossing assemblies is provided The support assembly 4 , the vertical embossing mechanism 6 is arranged on the top plate 207 and above the support assembly 4 .

[0043] The top surface of the base plate is provided with an adjustment groove 101, and two adjustment screw rods 105 are rotationally connected in the adjustment groove 101, and the direction of rotation of the two adjustment screw rods 105 is opposite, and the inner ends of t...

Embodiment 3

[0052] The structure of this embodiment is basically the same as that of Embodiment 2. The difference is that the drive mechanism 8 includes a drive box 801, a first rack 806 and a second rack 807, and a camshaft 802 is rotatably connected to the drive box 801. One end of the camshaft 802 is connected to the drive motor 803, the camshaft 802 is provided with a first cam 804 and a second cam 805, and one end of the first rack 806 and the second rack 807 passes through the drive box 801 respectively The top surface and the bottom surface of the rack are respectively meshed with the third gear 705 and the second gear 508, and the inner ends of the first rack 806 and the second rack 807 are respectively in contact with the wheel surfaces of the first cam 804 and the second cam 805, Moreover, the first rack 806 and the second rack 807 are provided with spring plates 808 , and the two spring plates 808 are respectively connected to the top surface and the bottom surface of the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com