A glass etching solution and its preparation method, an etching process using the glass etching solution and the prepared glass products

A technology of etching solution and glass, which is applied in the direction of chemical instruments and methods, surface etching compositions, etc., can solve the problems of difficult control of light transmittance and gloss particle density, and meet the needs of personalized customization, low concentration, Good light transmittance and gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

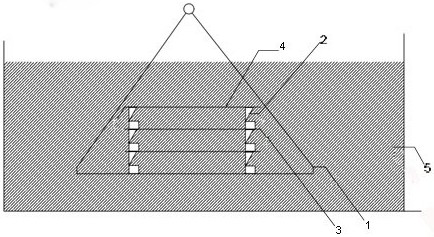

[0025] Embodiment 1: To prepare a glass etching solution, first add 40 parts by weight of water into the liquid medicine pool, then add 25 parts by weight of ammonium bifluoride and 2 parts by weight of sorbitol in sequence, stir evenly, then add 2 parts by weight of sulfuric acid, and keep stirring for at least 2 hours Then it can be used to etch glass. At the same time, if figure 1 As shown, spacers 2 are respectively placed at suitable positions around the plastic hanger 1 for placing the glass 3 to be etched. After the glass is cleaned and back protected, it is placed in the plastic hanger 1 so that the four sides of the glass 3 are placed on the pads. Plate 2, then acid cleaning (the final concentration of acid cleaning solution is 10% hydrofluoric acid and 5% sulfuric acid by mass fraction) pretreatment, then place the second glass 3 in the same way, and finally place the cover plate 4. Place the plastic hanger 1 in the glass etching solution pool 5, hang it out after 2...

Embodiment 2

[0027] Embodiment 2: To prepare an etching solution, first add 60 parts by weight of water into the liquid medicine pool, then add 35 parts by weight of ammonium bifluoride and 8 parts by weight of sorbitol in turn, stir evenly, then add 10 parts by weight of sulfuric acid, and keep stirring for at least 2 hours Can be used to etch glass. At the same time, if figure 1 As shown, spacers 2 are respectively placed at suitable positions around the plastic hanger 1 for placing the glass 3 to be etched. After the glass is cleaned and back protected, it is placed in the plastic hanger 1 so that the four sides of the glass 3 are placed on the pads. On the piece 2, then acid cleaning pretreatment, then place the second piece of glass 3 in the same way, and finally place the cover plate 4. Place the plastic hanger 1 in the glass etching solution pool 5, hang it out after 40 minutes of reaction, and quickly wash off the reactants on the glass surface with water. The particles become la...

Embodiment 3

[0029] Embodiment three: prepare etchant, first add 50 parts by weight of water in the liquid medicine pool, then drop into fluorine successively

[0030] 30 parts by weight of ammonium hydrogen chloride and 5 parts by weight of sorbitol were stirred evenly, and then 5 parts by weight of sulfuric acid was added, and kept stirring for at least 2 hours before being used for etching glass. At the same time, if figure 1 As shown, spacers 2 are respectively placed at suitable positions around the plastic hanger 1 for placing the glass 3 to be etched. After the glass is cleaned and back protected, it is placed in the plastic hanger 1 so that the four sides of the glass 3 are placed on the pads. On the piece 2, then acid cleaning pretreatment, then place the second piece of glass 3 in the same way, and finally place the cover plate 4. Place the plastic hanger 1 in the glass etching solution pool 5, hang it out after 20 minutes of reaction, and quickly wash off the reactants on the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com