Preparation method of aramid polypropylene beta nucleating agent

A beta nucleating agent, polypropylene technology, applied in the field of polymer additive modification, can solve problems such as unsatisfactory refinement effect and limited methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for dissolving an aromatic amide PPβ nucleating agent at room temperature by using concentrated sulfuric acid, and then precipitating through an anti-solvent to regulate the size and shape of the nucleating agent. The specific steps are as follows:

[0041] 1. Dissolving aromatic amide PPβ nucleating agent

[0042] Add 10 g of commercial TMB-5 into 200 ml of concentrated sulfuric acid, stir until the solution is clear and transparent, and obtain a uniform nucleating agent concentrated sulfuric acid solution.

[0043]Two, the nucleating agent in the solution in the anti-solvent precipitation step one

[0044] Slowly add 50ml of the solution prepared in step 1 into 1000ml of deionized water, stir for 10min, filter, and dry the obtained sample in an oven at 70°C for 24h;

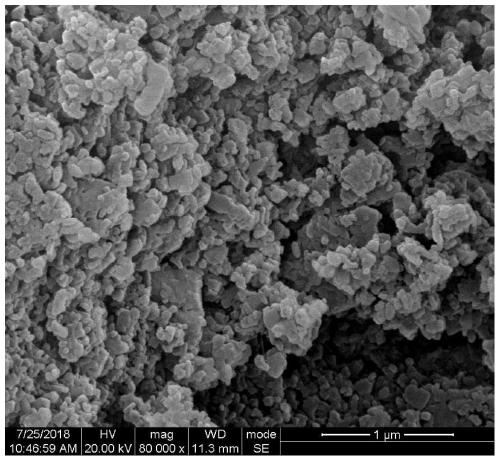

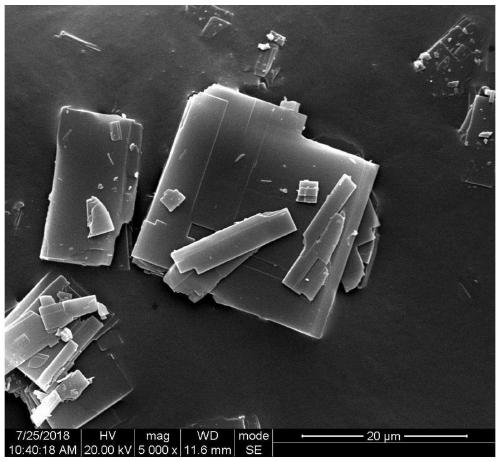

[0045] The morphology of the prepared nucleating agent was observed by JSM-5900LV scanning electron microscope (SEM). The morphology observation results of the prepared nucleating agent are as...

Embodiment 2

[0047] A method for dissolving an aromatic amide PPβ nucleating agent at room temperature by using concentrated sulfuric acid, and then precipitating through an anti-solvent to regulate the size and shape of the nucleating agent. The specific steps are as follows:

[0048] 1. Dissolving aromatic amide PPβ nucleating agent

[0049] Add 10g of TMB-5 into 200ml of concentrated sulfuric acid and stir until the solution is clear and transparent to obtain a uniform nucleating agent concentrated sulfuric acid solution.

[0050] Two, the nucleating agent in the solution in the anti-solvent precipitation step one

[0051] Slowly add 50ml of the solution prepared in step 1 into 1000ml of ethanol, stir for 10min, filter, and dry the obtained sample in an oven at 70°C for 24h;

[0052] The morphology of the prepared nucleating agent was observed by JSM-5900LV scanning electron microscope (SEM). The morphology observation results of the prepared nucleating agent are shown in the attached...

Embodiment 3

[0054] A method for dissolving an aromatic amide PPβ nucleating agent at room temperature by using concentrated sulfuric acid, and then precipitating through an anti-solvent to regulate the size and shape of the nucleating agent. The specific steps are as follows:

[0055] 1. Dissolving aromatic amide PPβ nucleating agent

[0056] Add 10g of TMB-5 into 200ml of concentrated sulfuric acid and stir until the solution is clear and transparent to obtain a uniform nucleating agent concentrated sulfuric acid solution.

[0057] Two, the nucleating agent in the solution in the anti-solvent precipitation step one

[0058] Slowly add 50ml of the solution prepared in step 1 into 1000ml of dimethyl sulfoxide, stir for 10 minutes, filter, and dry the obtained sample in an oven at 70°C for 24 hours;

[0059] The morphology of the prepared nucleating agent was observed by JSM-5900LV scanning electron microscope (SEM). The morphology observation results of the prepared nucleating agent are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com