Crystal form control method for TiO2 in TiO2-ACF photocatalysis material

A photocatalytic material and crystal form control technology, applied in the field of photocatalytic materials, can solve the problems of affecting use, poor loading firmness, poor dispersion, etc., and achieve good firmness, good catalytic performance, and avoid agglomeration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

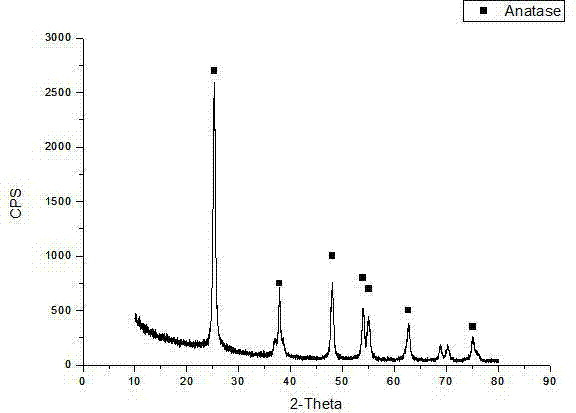

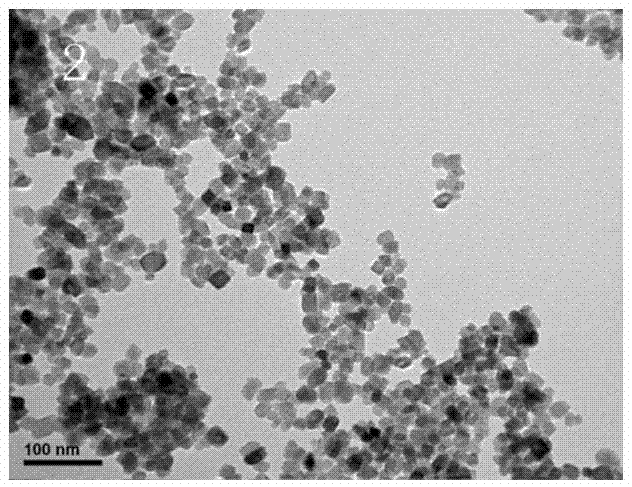

[0021] Measure and mix 35ml of deionized water, 0.01mol sulfuric acid and 40ml of ethanol to obtain solution A; weigh 12.2g of tetra-n-butyl titanate and dissolve in 40ml of ethanol to obtain solution B. Under stirring conditions, solution B was added dropwise to solution A to obtain TiO 2 Precursor solution. The resulting precursor solution was crystallized under high temperature and high pressure conditions to obtain TiO 2 suspension. The resulting TiO 2 The XRD spectrum of the particles is attached figure 1 As shown, the TEM image is attached figure 2 shown. It can be seen from the XRD spectrum that the TiO prepared by this method 2 Has a good anatase crystal form. It can be seen from the TEM image that the particles basically have no agglomeration phenomenon, and the dispersion is good.

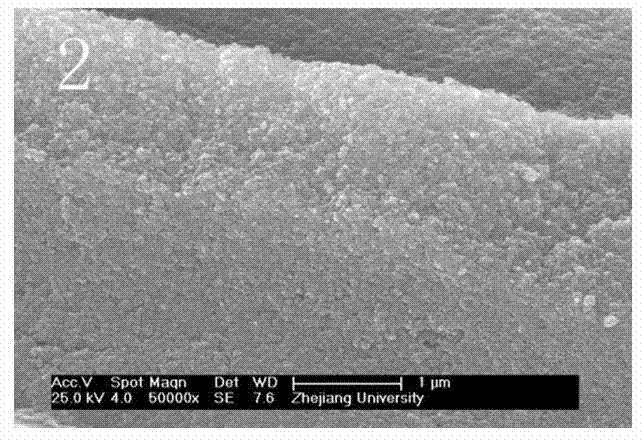

[0022] ACF of 10cm*10cm treated with nitric acid was added to the prepared TiO 2 impregnated in the suspension, taken out and dried to obtain TiO 2 - ACF catalyst. The ...

Embodiment 2

[0024] TiO 2 - Preparation of ACF catalyst: The catalyst was prepared in the same manner as in Example 1, except that 0.05 mol of sulfuric acid was added to the A solution. The loading strength of the catalyst reaches 82%. Evaluation of the prepared catalyst according to the same method as in Example 1, the degradation rate on the catalyst per unit area is 0.081 μmol / (cm 2 *h).

Embodiment 3

[0026] TiO 2 -Preparation of ACF catalyst: The catalyst was prepared in the same manner as in Example 1, except that the amount of deionized water was 6.5 ml, but sulfuric acid was not added. The loading strength of the catalyst reaches 81%. The prepared catalyst is evaluated according to the same method as in Example 1, and the degradation rate on the catalyst per unit area is 0.079 μmol / (cm 2 *h).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com