Reinforced polyamide moulding compounds with low haze and moulds therefrom

A technology of polyamide and molding compound, which can be applied to household appliances, other household appliances, chemical instruments and methods, etc., and can solve problems such as unreasonable economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment B1 to B4

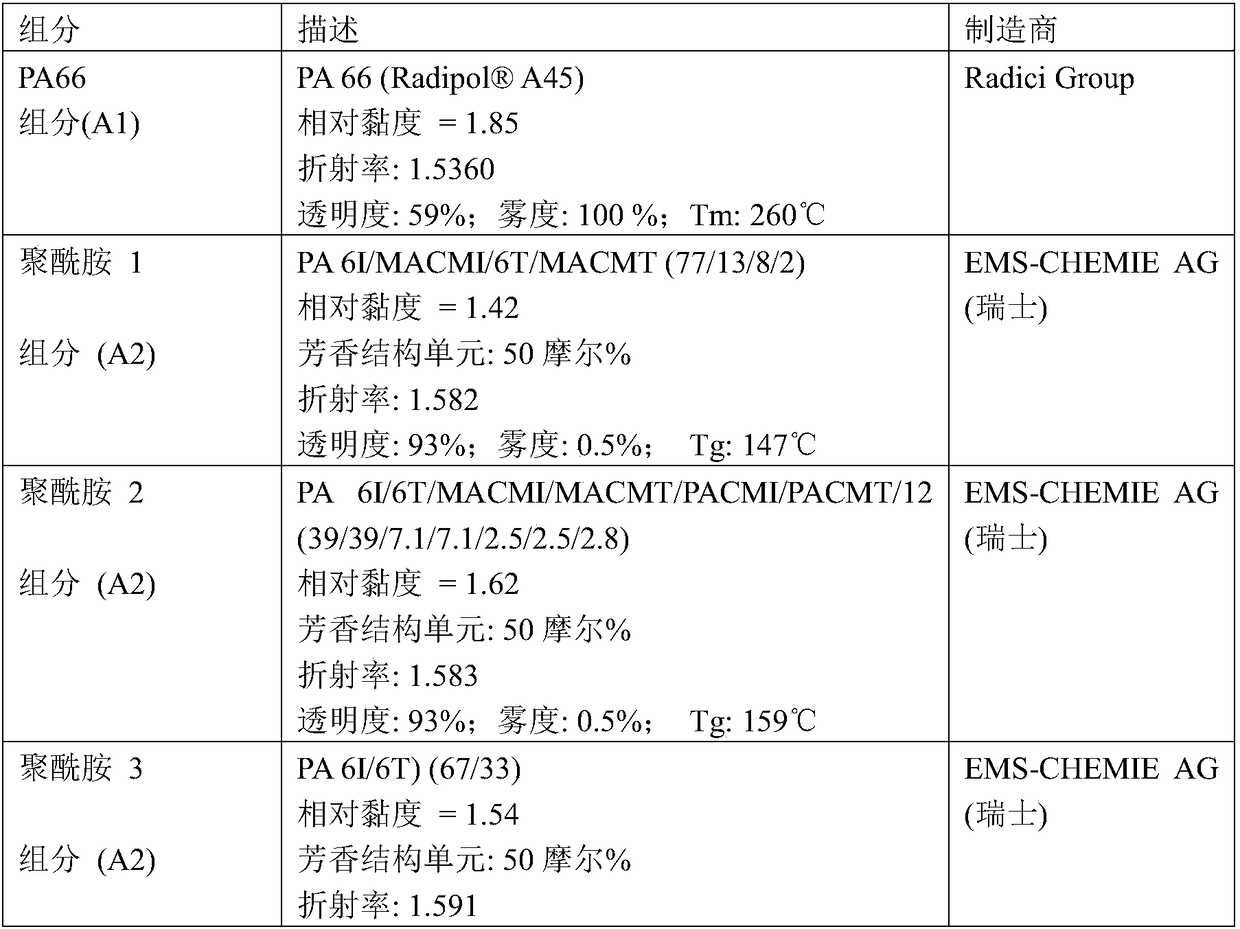

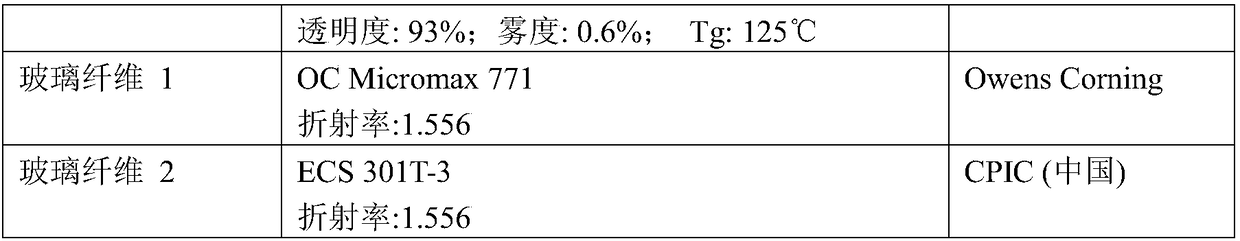

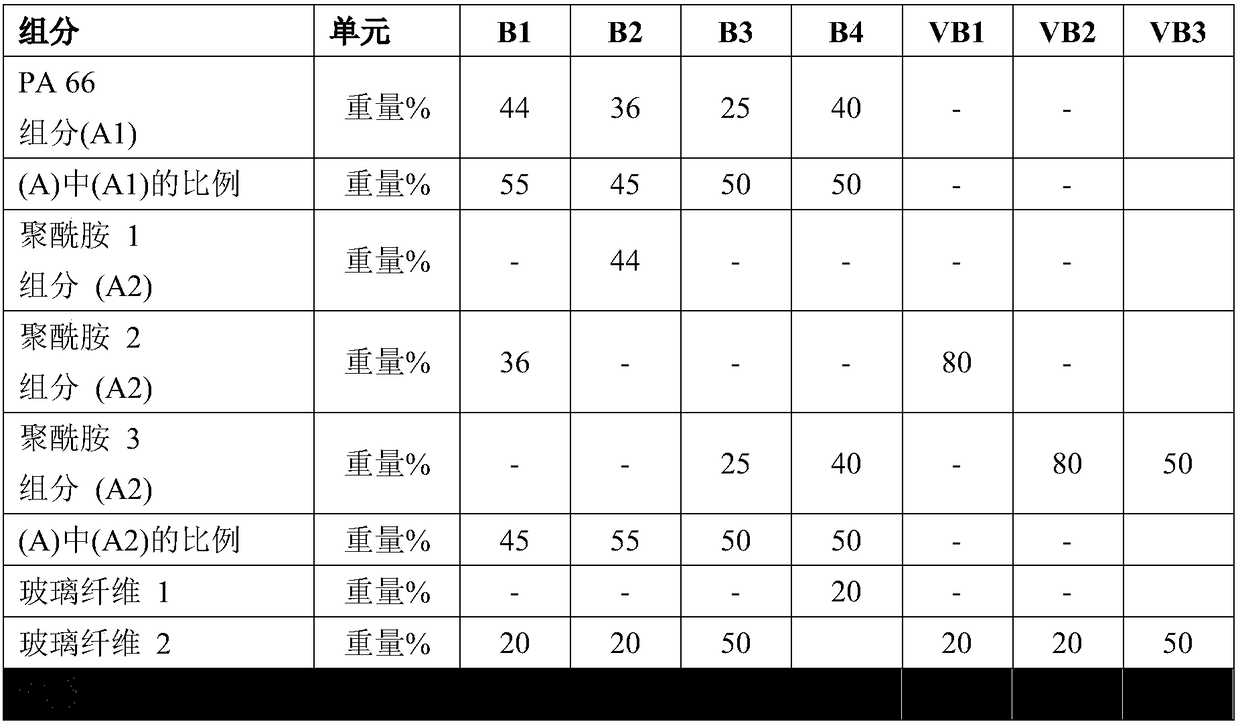

[0191] 3.2 Manufacture of polyamide molding compounds according to examples B1 to B4 and VB1 to VB3

[0192] The molding compounds of Examples B1 to B4 and Comparative Examples VB1 to VB3 were produced on a twin-screw extruder type ZSK25 from the company Werner & Pfleiderer. The polyamides (A1) and (A2) were metered into the feed of the extruder by means of metering trolleys in the quantity parts indicated in Table 2. The glass fibers used are fed into the polymer melt in the desired ratio via a side feeder and further homogenized in the barrel of the compounding machine.

[0193] The temperature of the first shell was set at 80°C; the temperature of the remaining shells was set from 270°C to 300°C in an increasing manner. Use a speed of 200 rpm and a throughput of 12 kg / h and degas the third zone before the nozzle in a stream of nitrogen. The polyamide molding compound delivered as a line was cooled in a water bath, pelletized, and the resulting pellets were dried at 80° C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com