Polyolefin composition comprising silicon-containing filler

A technology of composition and polyolefin, which is applied in the field of polyolefin composition with improved toughness, impact strength and heat resistance in the production of products, can solve the problems of composition cracking, stress whitening, and particle surface peeling, and achieve Effect of improved surface quality, high heat deflection temperature, improved scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

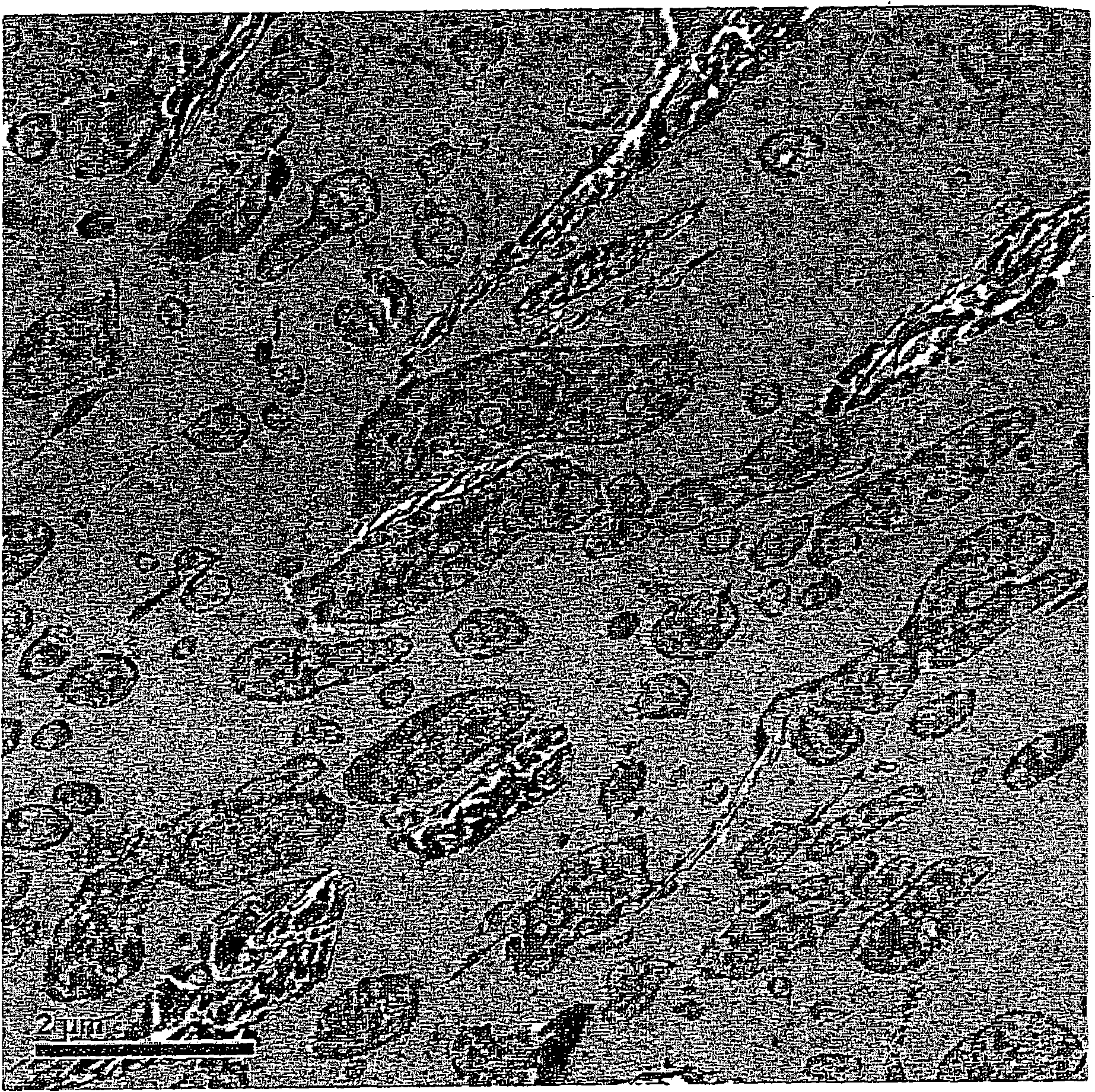

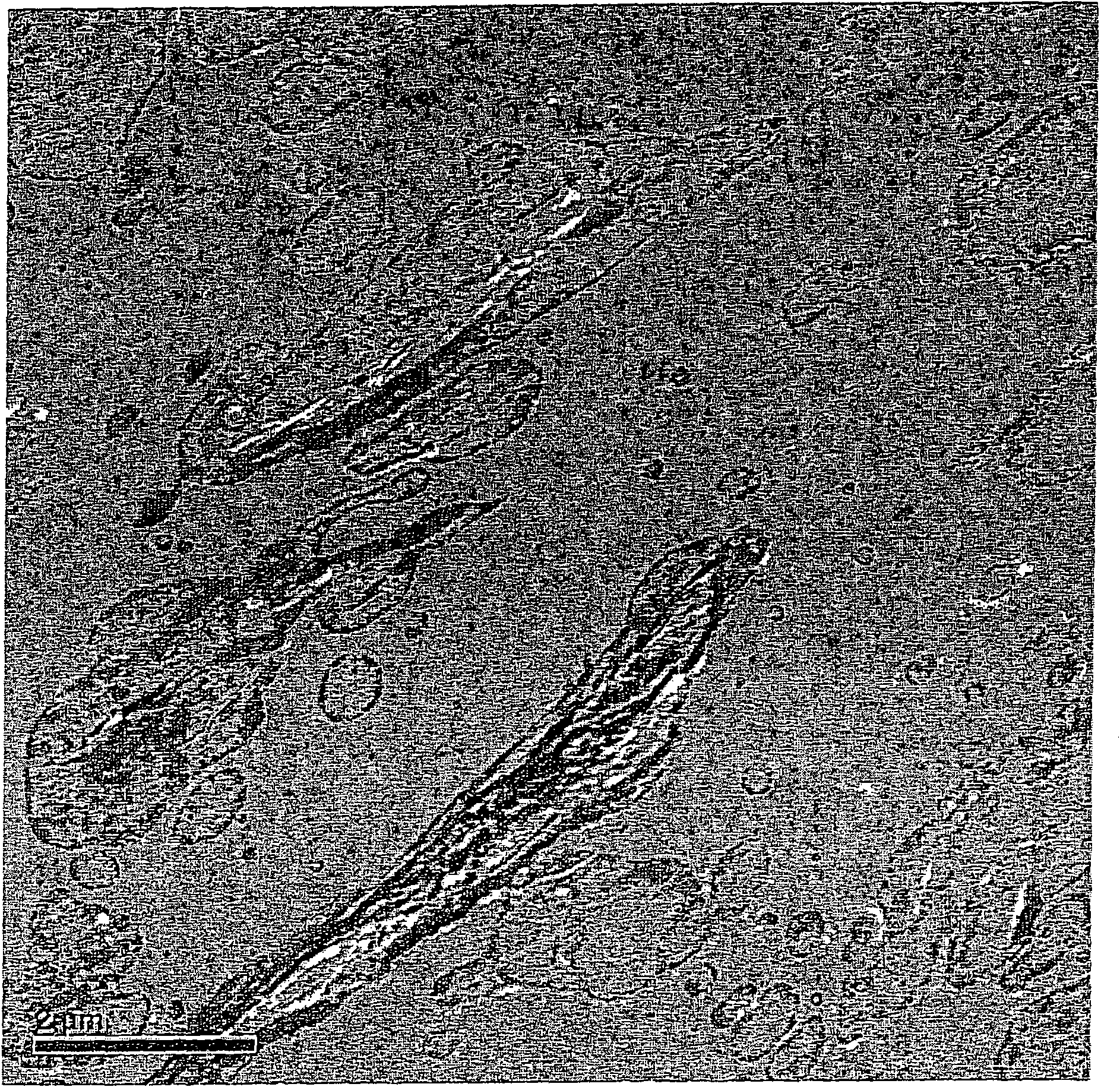

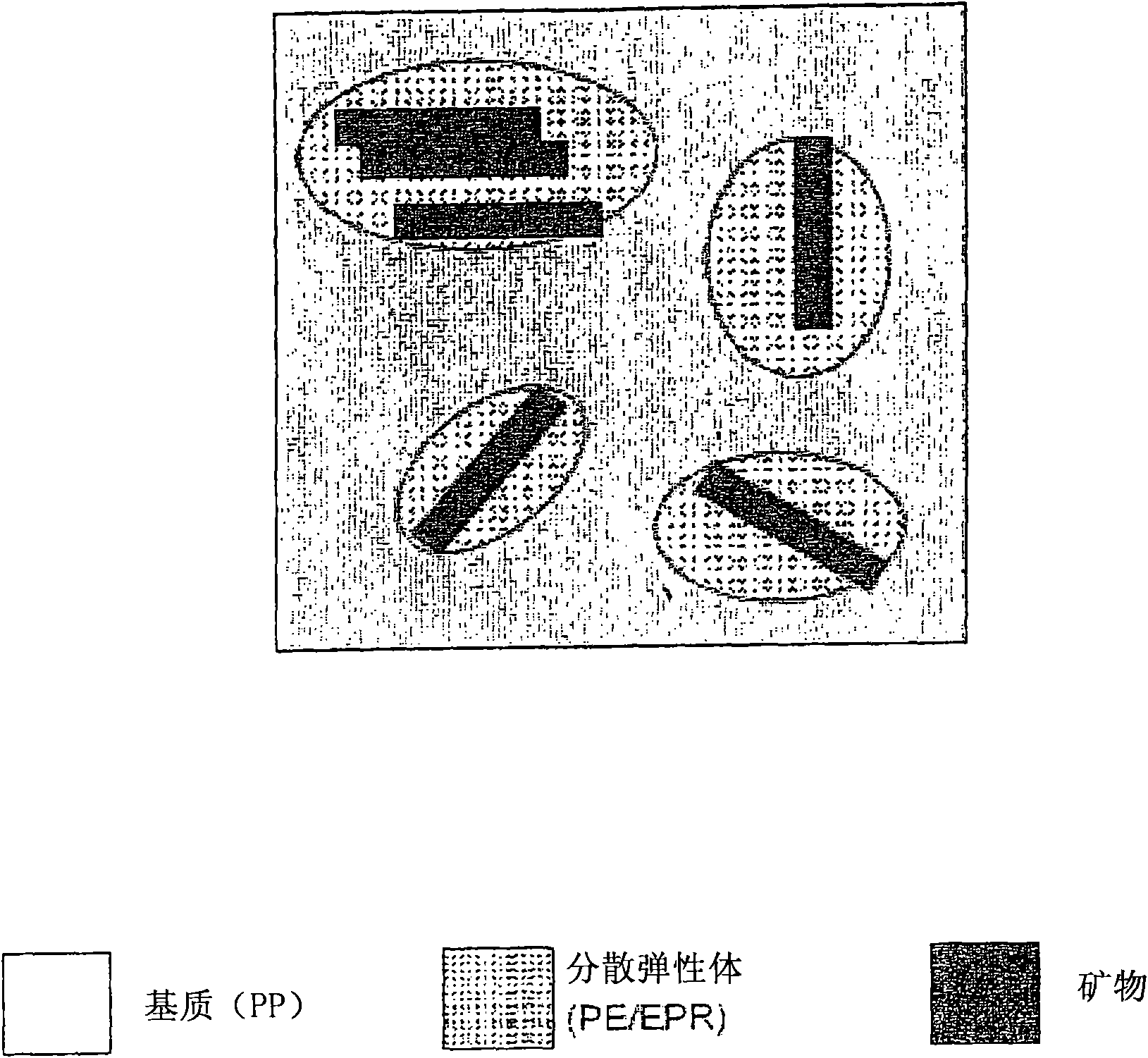

Method used

Image

Examples

Embodiment 1

[0138] 87.75 wt% PPX104 was used as matrix phase, 2.0 wt% LE4481 as silane-copolymerized polyethylene, 10.0 wt% talc and 0.25 wt% catalyst masterbatch CAT-MB50.

Embodiment 2

[0140] 87.75 wt% PPX104 was used as matrix phase, 2.0 wt% LE4423 as silane-copolymerized polyethylene, 10.0 wt% talc and 0.25 wt% catalyst masterbatch CAT-MB50.

Embodiment 3

[0142] 84.75 wt% of PPX104 as matrix phase, 5.0 wt% of LE4423 as silane-copolymerized polyethylene, 10.0 wt% of talc and 0.25 wt% of catalyst masterbatch CAT-MB50 were used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com