Anticorrosive electrode material, LCD and their preparing process

A technology for liquid crystal display device and electrode corrosion, which is applied in the field of liquid crystal display device and anti-corrosion materials for electrodes, can solve problems such as inability to effectively prevent electrode corrosion, and achieve the effects of excellent mechanical properties, good anti-corrosion effect and high thermal deformation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

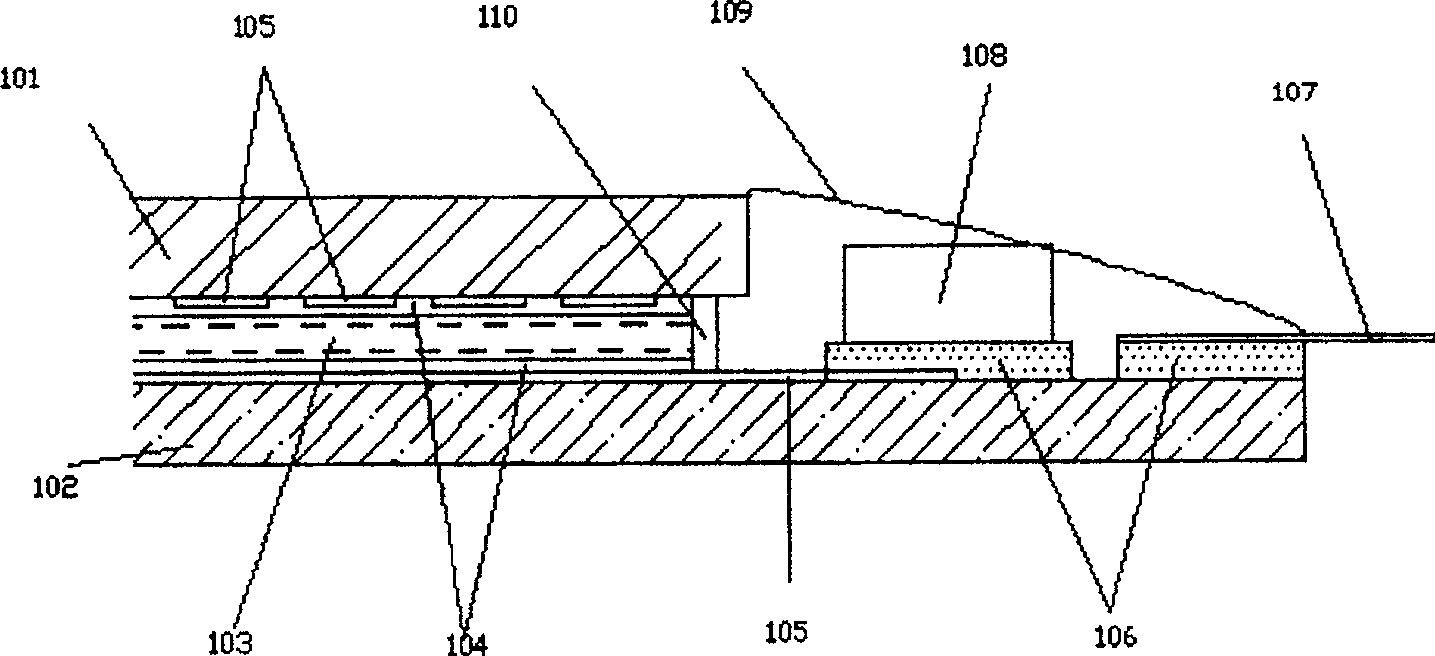

[0029] The present invention also provides a method for preparing a liquid crystal display device, which comprises placing liquid crystal and electrodes into two substrates, and then contacting a material for preventing electrode corrosion with a terminal portion of the substrate, wherein the material for preventing electrode corrosion It is the material for preventing electrode corrosion provided by the present invention. Specifically, in the present invention, the material for preventing electrode corrosion is made into a film, and then the obtained film is hot-pressed and covered on the terminal part of the substrate of the liquid crystal display device, so that the electrode corrosion prevention material covers the terminal part electrode without affecting the binding The fixed driver IC and flexible circuit board shall prevail.

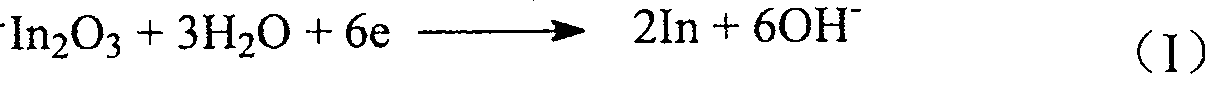

[0030] In the present invention, the anti-corrosion performance of the electrode anti-corrosion material is represented by the time that the liq...

Embodiment 1

[0033] This example is used to illustrate the preparation method of the material for preventing electrode corrosion provided by the present invention.

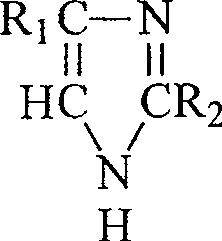

[0034] 1 gram of solid bisphenol A epoxy resin with a degree of polymerization of 2.5 (produced by Baling Petrochemical Company, EP 01661-310) was added to 200 ml of methyl ethyl ketone, and then 99 grams of liquid bisphenol with a degree of polymerization of 1.5 was added after stirring evenly. A epoxy resin (produced by Baling Petrochemical Company, EP 01551-310), add 10 grams of curing agent 2-ethyl 4-methylimidazole (Shanghai Chenri Chemical Co., Ltd.) after continuing to stir for 10 minutes, and continue to stir for 30 minutes , and then add 1 gram of acrylic plastic particles with a diameter of 8 microns. After stirring again for 10 minutes, the obtained mixture was all coated on a layer of release film by a roller coating process. After natural air-drying to remove the solvent, a thickness of 0.02 The millimeter-sized f...

Embodiment 2

[0036] This example is used to illustrate the preparation method of the material for preventing electrode corrosion provided by the present invention.

[0037] Add 15 grams of solid bisphenol A epoxy resin (produced by Baling Petrochemical Company, EP 01671-310) with a degree of polymerization of 4.5 into 200 ml of methyl ethyl ketone, stir evenly and then add 85 grams of liquid bisphenol A with a degree of polymerization of 1.2 Epoxy resin (produced by Baling Petrochemical Company, EP 01451-310), add 5 grams of curing agent 2-ethyl 4-methylimidazole (Shanghai Chenri Chemical Co., Ltd.) after continuing to stir for 10 minutes, continue to stir for 30 minutes, Then 1 gram of acrylic plastic particles with a diameter of 5 microns was added, and after stirring for 10 minutes again, the obtained mixture was all coated on a layer of release film by a roller coating process, and the solvent was naturally air-dried to obtain a thickness of 0.025 mm. The film S2 is the anti-corrosion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com