Method for improving performance of bearing bush steel backing

A technology of bearing bush and steel back, applied in the field of bearing bush steel back, can solve the problems of low strength of bearing bush steel back, easy deformation of bearing bush steel back, affecting normal use, etc., so as to improve deformation stability, reduce dimensional change, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

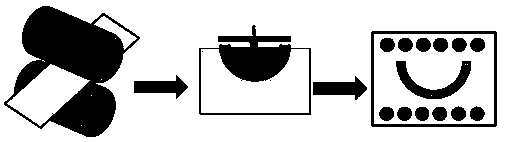

[0023] Rolling treatment: the plate-shaped bearing material is passed through the gap between a pair of rotating rolls, and the cross-section of the plate-shaped bearing material is reduced due to the compression of the rolls; bending shaping: the rolled plate is processed by a press brake The raw material of the bearing pad is bent to form a semicircle; low-temperature heat treatment: put the raw material of the plate-shaped bearing pad after bending and shaping into a heat treatment machine for heating, and then perform size processing and coating treatment after heating to obtain the finished bearing pad, heat treatment The temperature is 200℃, the holding time is 120min, the heating rate of heat treatment is 1℃ / min, and the heat treatment machine is heated by a heating coil wound internally into a ring or other shape. The steel back of the bearing bush needs to be coated before coating treatment. Sand blasting, coating treatment includes primary spraying and secondary spray...

Embodiment 2

[0025] Rolling treatment: the plate-shaped bearing material is passed through the gap between a pair of rotating rolls, and the cross-section of the plate-shaped bearing material is reduced due to the compression of the rolls; bending shaping: the rolled plate is processed by a press brake The raw material of the bearing pad is bent to form a semicircle; low-temperature heat treatment: put the raw material of the plate-shaped bearing pad after bending and shaping into a heat treatment machine for heating, and then perform size processing and coating treatment after heating to obtain the finished bearing pad, heat treatment The temperature is 220°C, the holding time is 70min, the heating rate of heat treatment is 2°C / min, and the heat treatment machine is heated by a heating coil wound internally into a ring or other shape. The steel back of the bearing bush needs to be coated before coating treatment. Sand blasting, coating treatment includes primary spraying and secondary spra...

Embodiment 3

[0027] Rolling treatment: the plate-shaped bearing material is passed through the gap between a pair of rotating rolls, and the cross-section of the plate-shaped bearing material is reduced due to the compression of the rolls; bending shaping: the rolled plate is processed by a press brake The raw material of the bearing pad is bent to form a semicircle; low-temperature heat treatment: put the raw material of the plate-shaped bearing pad after bending and shaping into a heat treatment machine for heating, and then perform size processing and coating treatment after heating to obtain the finished bearing pad, heat treatment The temperature is 250°C, the holding time is 90min, the heating rate of heat treatment is 3°C / min, and the heat treatment machine is heated by a heating coil wound internally into a ring or other shape. The steel back of the bearing bush needs to be coated before coating treatment. Sand blasting, coating treatment includes primary spraying and secondary spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com