High-temperature alloy mandrel applied to planetary rolling mill for rolling copper and copper alloy and preparation method thereof

A high-temperature alloy and planetary rolling mill technology, applied in metal processing equipment, cores, manufacturing tools, etc., can solve the problems of high hardness and strength of copper alloy, easy sticking of copper on the outer surface of the mandrel, and low heat dissipation efficiency of the mandrel, etc., to achieve Increase heat corrosion resistance, low probability of copper sticking phenomenon, and good comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

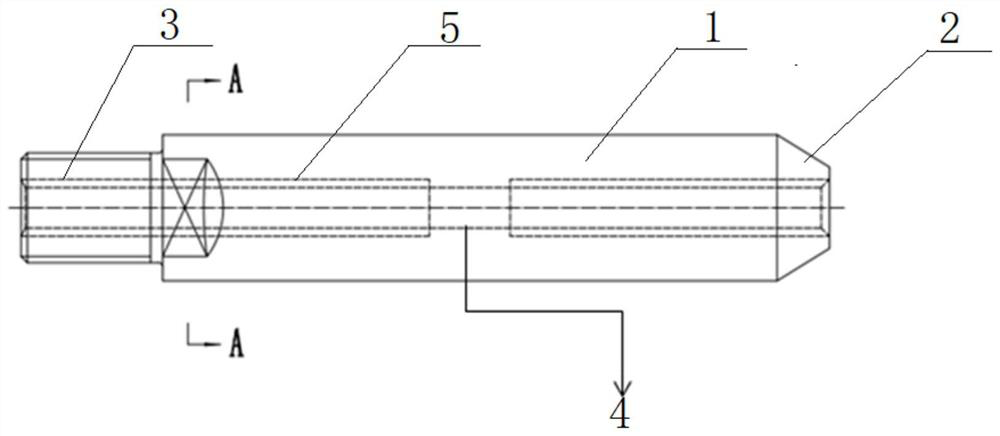

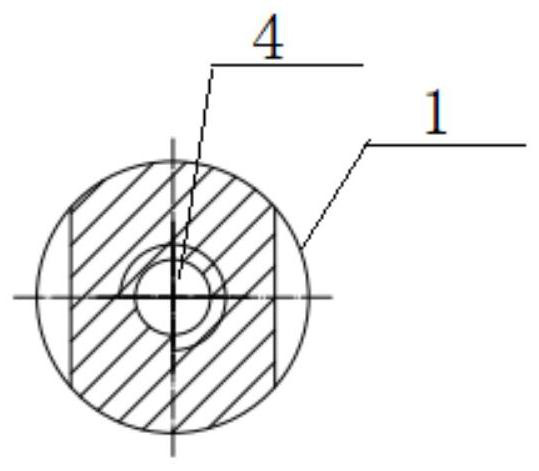

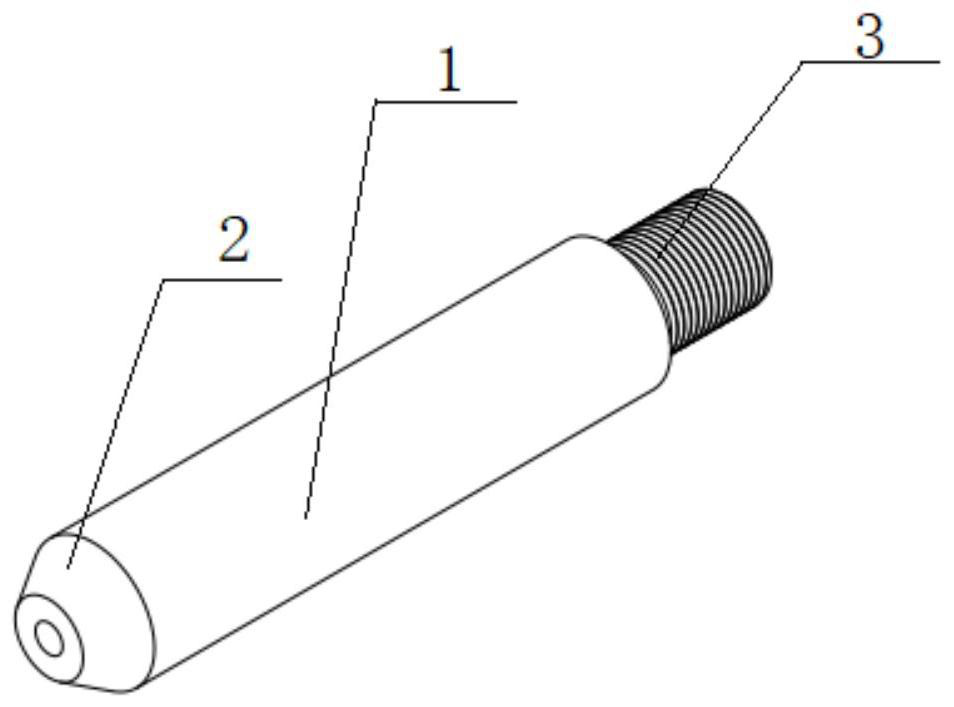

[0028] It includes a sizing belt 1, a guide cone 2, an external thread 3, a cooling hole 4 and an internal thread 5; the front end of the sizing belt 1 is provided with a guide cone 2, and the end is provided with an external thread 3; There are cooling holes 4, and internal threads 5 are arranged along the cooling holes 4.

[0029] The mandrel provided by the invention has a sizing band length of 145-155mm, a circular threaded part of 30-40mm, and a truncated conical guide cone part of 10-20mm, and the cooling hole runs through the whole mandrel such as figure 1 shown. The surface of the mandrel cooling hole is processed with internal threads, which increases the heat dissipation during the rolling process, thereby increasing the service life of the mandrel. In the center of the mandrel sizing zone, the wall thickness of 2-4cm does not process the internal thread.

[0030] The mandrel provided by the invention is used for rolling copper ingots of various copper and copper a...

Embodiment 2

[0032] A method for preparing a high-temperature alloy mandrel applied to a planetary rolling mill for rolling copper and copper alloys, the steps are as follows:

[0033] (1) Vacuum melting: In terms of mass percentage, take Cr 12.7%, Mo 4.5%, Al 6%, Ti 0.75%, Nb 2.3%, the rest is Ni, and add control trace elements B 0.012%, C 0.14%, Zr 0.12%, smelting under vacuum not higher than 5MPa, casting temperature is 1480℃, to prepare superalloy master alloy;

[0034] (2) Investment casting: The master alloy prepared in step (1) is removed from the riser, and the outer surface is ground to remove scale as the secondary melting raw material for investment casting; it is remelted and cast into the mold shell by vacuum induction melting to prepare For blanks close to the size of the mandrel, the mold shell is baked at 850°C and held for 3 hours; the refining temperature is 1510°C, the casting temperature is 1430°C, the melting vacuum is not higher than 5MPa, and the melting time is 30 m...

Embodiment 3

[0039] (1) Vacuum smelting: by weight percentage, take Cr 12.5%, Mo 4.2%, Al 6.2%, Ti 0.8%, Nb 2.2%, the rest is Ni, and the rest is Ni, and add control trace elements B 0.015%, C 0.12%, Zr 0.12%, smelting under vacuum not higher than 5MPa, casting temperature is 1490℃, to prepare superalloy master alloy;

[0040] (2) Investment casting: The master alloy prepared in step (1) is removed from the riser, and the outer surface is ground to remove scale as the secondary melting raw material for investment casting; it is remelted and cast into the mold shell by vacuum induction melting to prepare For billets close to the size of the mandrel, the mold shell baking temperature is 1000°C, and the heat preservation is 3h; the refining temperature is 1530°C, the casting temperature is 1430°C, the melting vacuum degree is not higher than 5MPa, and the melting time is 20min;

[0041] (3) Hot isostatic pressing treatment: hot isostatic pressing treatment is performed on the casting prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com